Method of separating components of coal tar

A separation method and technology for coal tar, applied in the field of coal chemical industry, can solve the problems of cumbersome separation method and the like, and achieve the effects of easy availability of solvent, high reliability and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

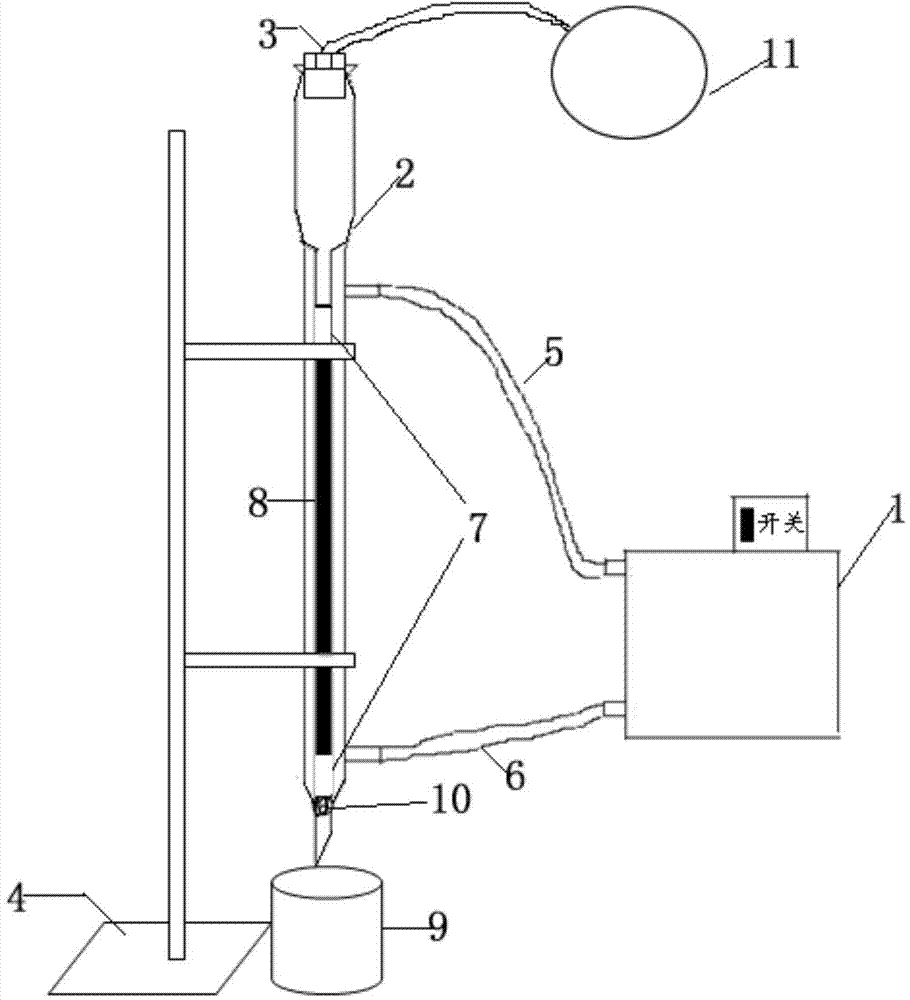

Method used

Image

Examples

Embodiment 1

[0037] 1) Place a small ball of dry absorbent cotton at the lower end of the separation column, and add 1cm of quartz sand, 120cm of column chromatography silica gel, and 1cm of quartz sand in sequence;

[0038] 2) Rinse the separation column with 100ml n-hexane.

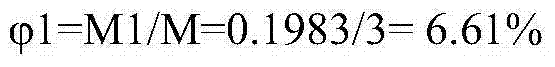

[0039] 3) Adding coal tar whose total mass M is 3g. A receiving bottle 1 is placed at the lower port of the separation column for elution with n-hexane.

[0040] 4) Test with an aromatic indicator prepared by concentrated sulfuric acid (99wt%) and formaldehyde at a volume ratio of 50:1 to observe whether the end point is reached.

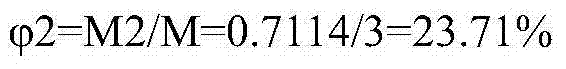

[0041] 5) When the aromatic hydrocarbon indicator turns red, replace the elution solvent with toluene, and replace the receiving bottle 2 at the same time.

[0042] 6) The refractive index of the receiving liquid is consistent with that of the toluene solvent, and the solvent is replaced with methanol, and the receiving bottle 3 is replaced at the same time.

[0043] 7) The refractive ...

Embodiment 2

[0056] 1) Place a small ball of dry absorbent cotton at the lower end of the separation column, and add 0.8cm high quartz sand, 140cm column chromatography silica gel, and 1.2cm quartz sand in sequence;

[0057] 2) Rinse the separation column with 100ml of n-pentane.

[0058] 3) Adding coal tar whose total mass M is 3g. The receiving bottle 1 is placed at the lower port of the separation column, and is eluted with n-pentane.

[0059] 4) Test with an aromatic indicator prepared by concentrated sulfuric acid (99wt%) and formaldehyde at a volume ratio of 50:1 to observe whether the end point is reached.

[0060] 5) When the aromatic hydrocarbon indicator turns red, replace the elution solvent with ethylbenzene, and replace the receiving bottle 2 at the same time.

[0061] 6) The refractive index of the receiving liquid is consistent with that of the toluene solvent, and the solvent is replaced with methanol, and the receiving bottle 3 is replaced at the same time.

[0062] 7) ...

Embodiment 3

[0075] 1) Place a small ball of dry absorbent cotton at the lower end of the separation column, and then add quartz sand with a height of 1.2cm, 100cm column chromatography silica gel, and 0.8cm quartz sand;

[0076] 2) Rinse the separation column with 100ml butane.

[0077] 3) Add coal tar whose total mass M is 3.24g. The receiving bottle 1 is placed at the lower port of the separation column, and is eluted with butane.

[0078] 4) Test with an aromatic indicator prepared by concentrated sulfuric acid (95wt%) and formaldehyde at a volume ratio of 51:1 to observe whether the end point is reached.

[0079] 5) When the aromatic hydrocarbon indicator turns red, replace the elution solvent with benzene, and replace the receiving bottle 2 at the same time.

[0080] 6) The refractive index of the receiving liquid is consistent with that of the toluene solvent, and the solvent is replaced with ethanol, and the receiving bottle 3 is replaced at the same time.

[0081]7) The refract...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com