Movement part-free low-consumption and high-efficiency ammonia water, tar and tar residue separation dewatering integration tank

A technology for separation and dehydration and tar residue, applied in the direction of tar removal through water, liquid separation, separation methods, etc., can solve the problems of difficult control of tar moisture and high energy consumption, and achieve the avoidance of transportation inconvenience, low energy consumption, and separation long time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

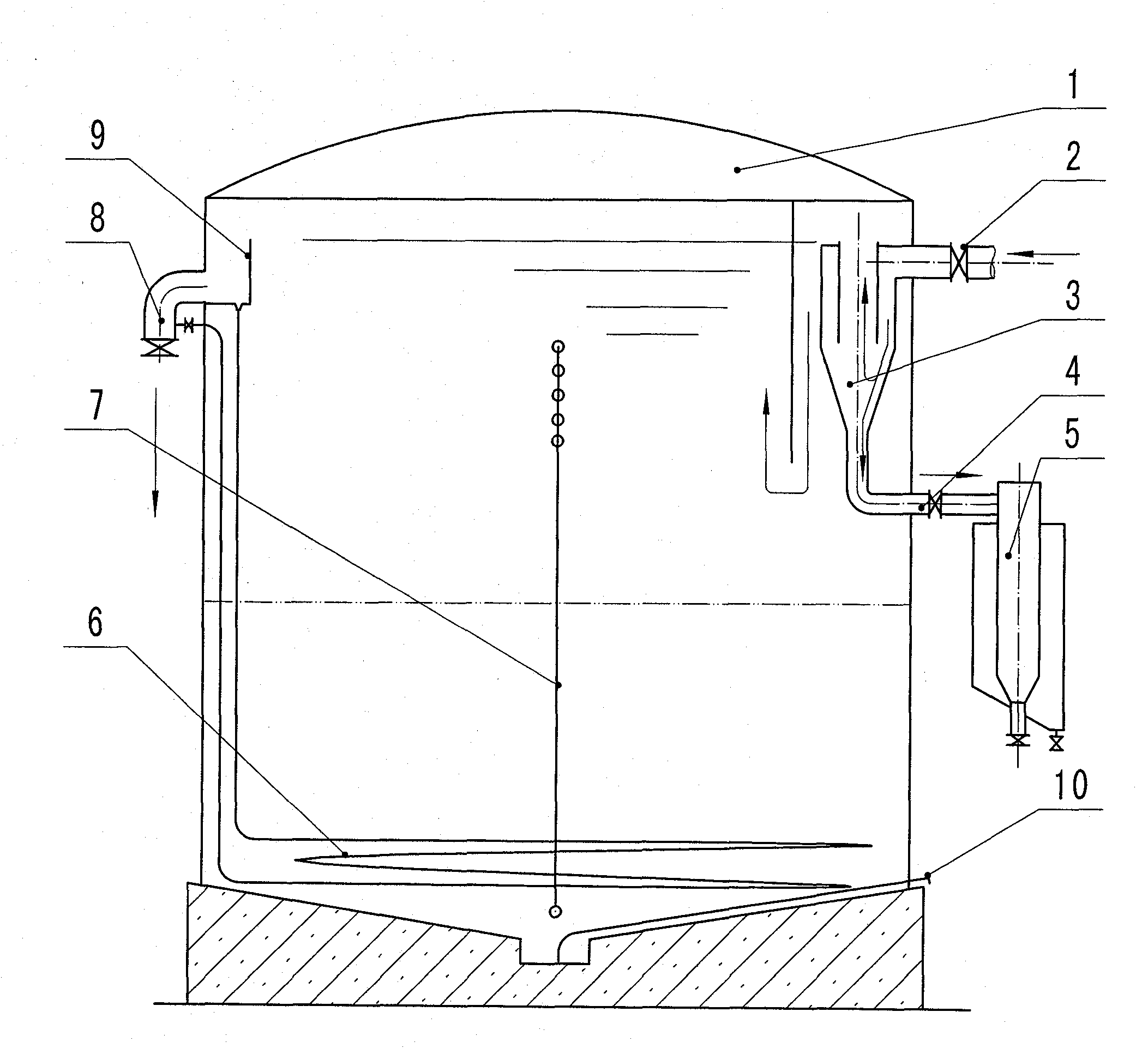

[0017] Referring to the accompanying drawings, the integrated tank for the separation and dehydration of ammonia water, tar and tar residue with low consumption and high efficiency without moving parts consists of a tank body, a mixed liquid inflow pipe, a tar outlet pipe, an ammonia water outlet pipe, a tar residue outlet pipe, a heating coil, and a tar residue separator , tar residue dehydrator, and cleaning pipe. The mixed liquid containing ammonia water, tar, and tar residue enters the tar residue separator 3 from the mixed liquid inlet pipe 2, and the tar residue is separated, the mixed liquid of ammonia water and tar floods into the tank body 1, and the tar residue mixture passes through the outlet pipe 4 Enter the tar residue dehydrator 5 to dehydrate the tar residue. The mixed solution flooded into the tank is naturally separated into upper and lower layers due to the difference in specific gravity between ammonia water and tar. The specific gravity of ammonia water i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com