Method for processing low-temperature pyrolyzed coal tar

A technology of low-temperature coal tar and processing method, which is applied in the processing of tar, the processing of removing tar by water, and the processing of refining tar by chemical method, etc., can solve problems such as comprehensive utilization and waste of resources, achieve reasonable utilization, low cost, and solve The effect of difficult separation of oil and water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

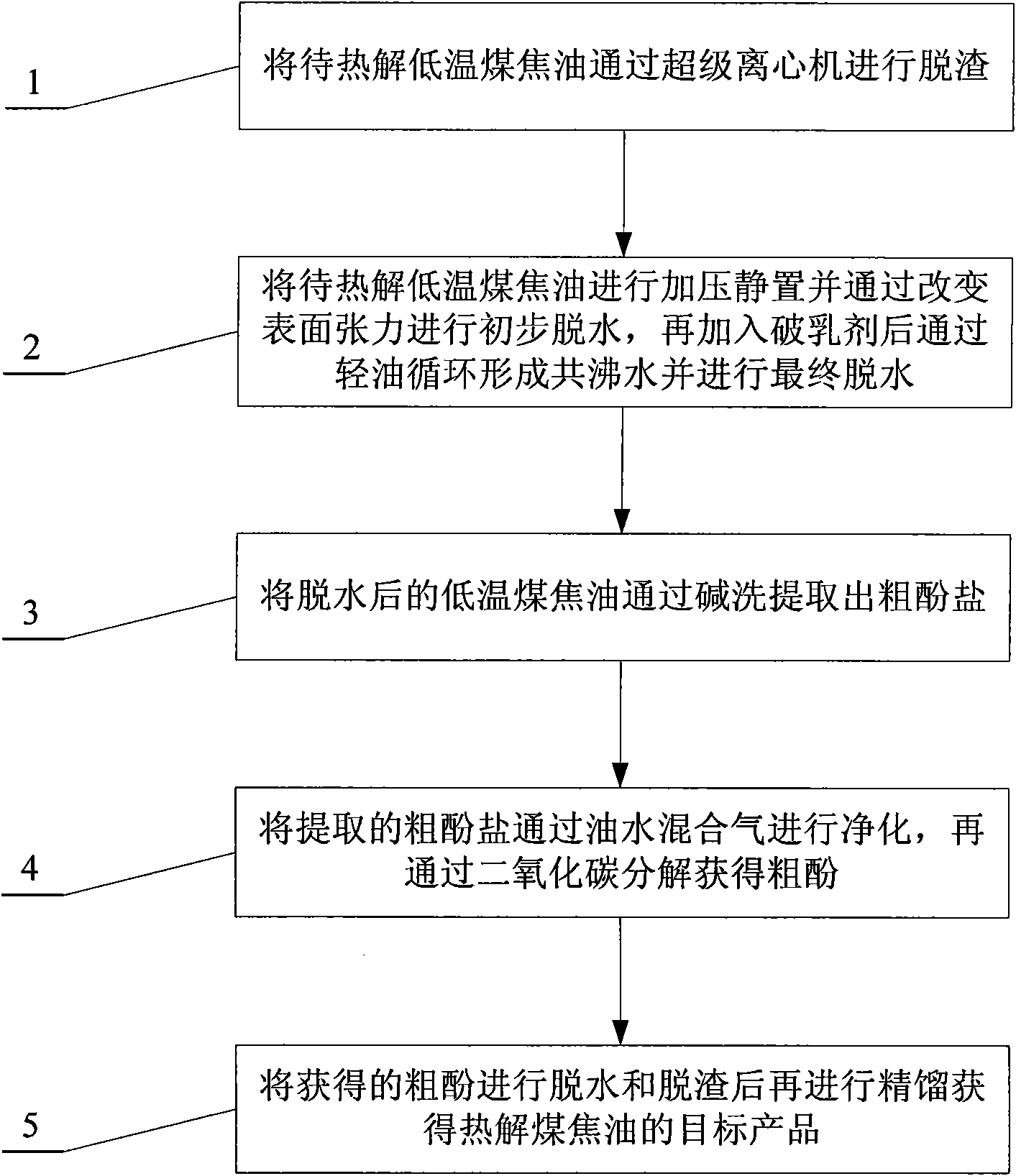

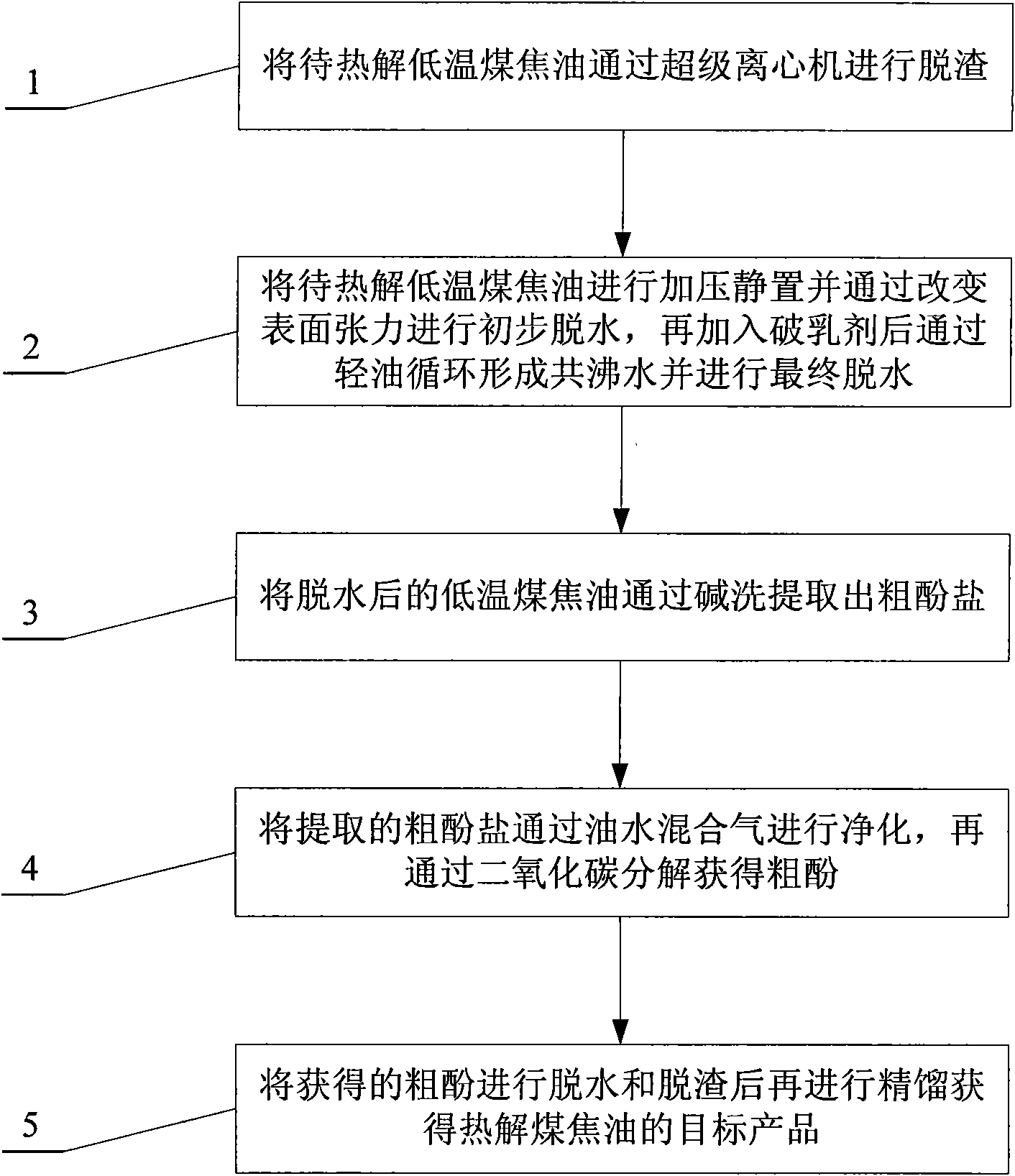

[0013] This specific embodiment provides a processing method for low-temperature pyrolysis coal tar, which is mainly composed of five parts: preprocessing before processing, alkali extraction, crude phenate purification, crude phenol refining, and processing of the remaining part after alkali extraction. The technical scheme is clearly described, and will be described below in conjunction with the accompanying drawings of the description, such as figure 1 As shown, the method may specifically include:

[0014] In step 1, the low-temperature coal tar to be pyrolyzed is deslagged through a super centrifuge.

[0015] In order to obtain a higher extraction rate of crude phenoxide, the low-temperature coal tar to be pyrolyzed can be pre-deslagged first, and the coarse slag can be removed by a high-speed centrifuge to obtain the low-temperature coal tar to be pyrolyzed. Wherein said super centrifuge can select the centrifuge that rotating speed is 50000r / min.

[0016] In step 2, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com