Technique and device for preventing deposition and blockage of tar residues of tar system

A technology for tar residue and tar, which is applied in the field of processes and devices for preventing tar residue deposition and clogging in a tar system, can solve problems such as tar deposition clogging, etc., and achieve the effects of improving separation effect, reducing the number of equipment pipeline maintenance, and improving tar residue deposition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

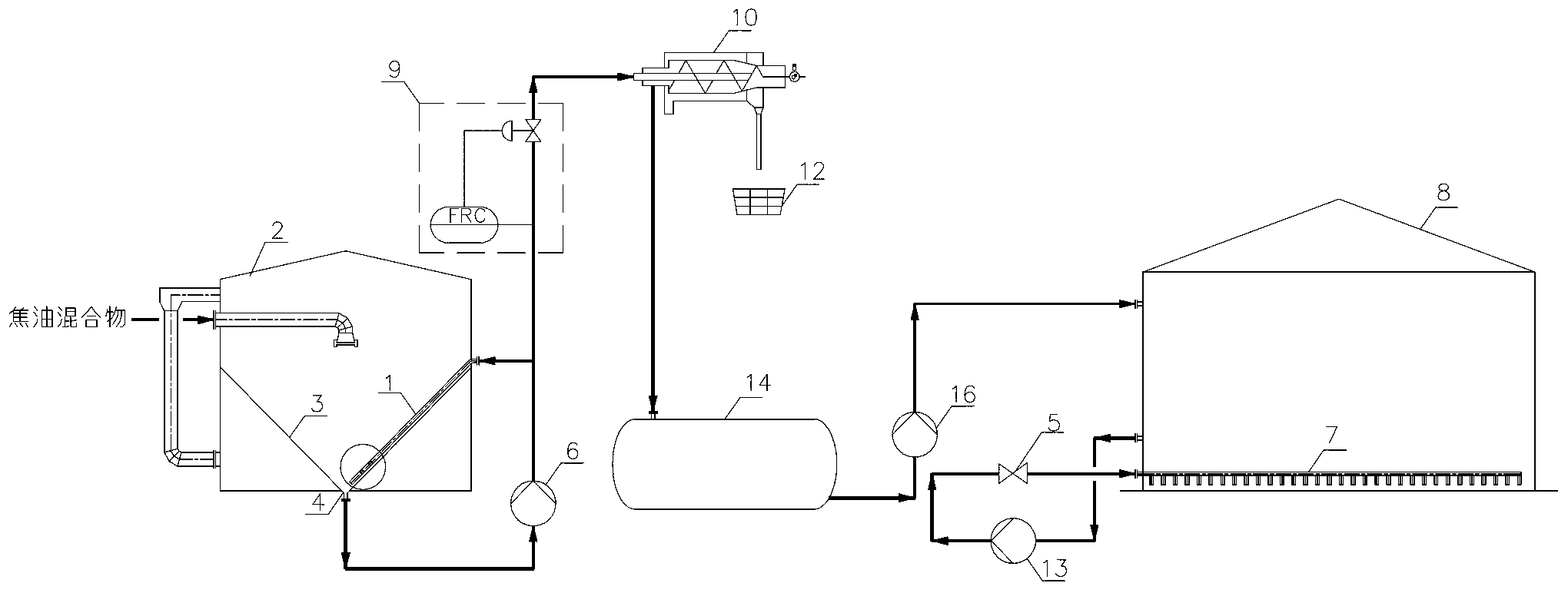

[0021] See figure 1 , is a process flow diagram for preventing tar residue deposition and clogging in the tar system of the present invention. The bottom of the tar ammonia water separation tank 2 flows through the intermediate pump 6 and the flow adjustment device 9 is connected with the centrifuge 10, and the solid tar residue separated by the centrifuge 10 enters the tar Slag box 12, the separated tar enters tar tank 14, and the outlet of tar tank 14 enters tar storage tank 8 through tar pump 16, and the bottom of tar storage tank is provided with stirring circulation pump 13.

[0022] The tar mixture containing tar residue is directly extracted from the cone bottom opening 4 of the tar ammonia water separation tank 2 by the middle pump 6, and the middle pump 6 drives a part of the mixture into the fluid dredging device 1 to stir the cone botto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com