Dehydration device and dehydration method for aqueous vinyl chloride monomer

A technology for water-containing vinyl chloride and vinyl chloride monomers, which is applied in the disproportionation separation/purification of halogenated hydrocarbons, organic chemistry, etc., can solve the problem of high production cost of dehydration devices, and achieve safe and reliable dehydration effects, convenient operation and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

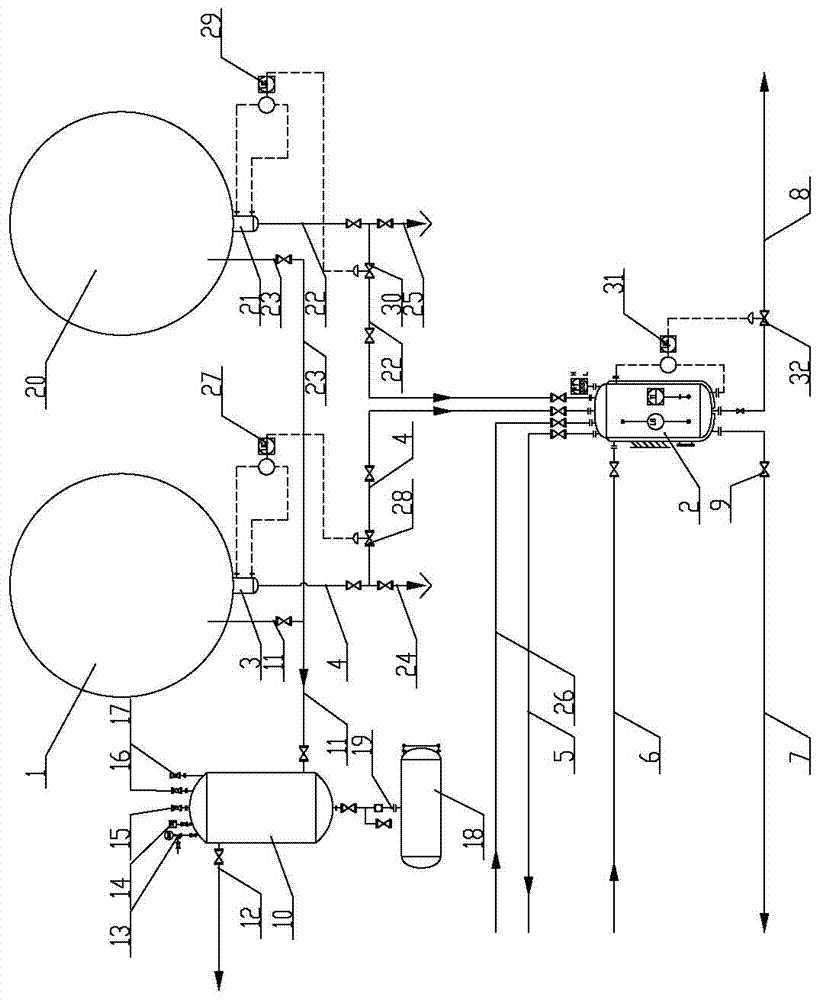

[0022] Embodiment 1, as attached figure 1 As shown, the dehydration device of the aqueous vinyl chloride monomer includes a first spherical tank 1 and a steam-water separator 2; the bottom of the first spherical tank 1 is integrally fixed with the first accumulated water communicated with the cavity of the first spherical tank 1 Bag 3 has a water outlet end at the bottom of the first water accumulation bag 3, and has a vinyl chloride recovery port and a first water inlet end at the top of the steam-water separator 2; the water outlet end of the first water accumulation bag 3 and the soda water The first water inlet end of the separator 2 is fixedly connected together through the first water outlet pipe 4, and a vinyl chloride recovery pipe 5 is fixedly installed on the vinyl chloride recovery port end of the steam-water separator 2, and there is steam at the upper part of the steam-water separator 2. At the inlet end, the steam pipe 6 is fixedly installed on the steam inlet en...

Embodiment 2

[0029] Embodiment 2, as attached figure 1 Shown, the dehydration method of the dehydration device that this uses hydrous vinyl chloride monomer, carries out according to the following steps: the first step, hydrous vinyl chloride monomer is left standstill in the first spherical tank 1 or the second spherical tank 20 for 6h to After standing for 8 hours, the water-containing vinyl chloride monomer is divided into upper and lower layers. The upper layer is the vinyl chloride monomer containing a small amount of water, and the lower layer is water containing a small amount of vinyl chloride monomer. The vinyl chloride monomer containing a small amount of water passes through the first outlet The pipe 11 or the second liquid outlet pipe 23 enters the solid alkali drier 10 for drying treatment, and after the drying treatment, it is sent to the polymerization process through the vinyl chloride monomer pipeline 12; in the second step, the water containing a small amount of vinyl chlo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com