Patents

Literature

33results about How to "Meet the requirements of subsequent processing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

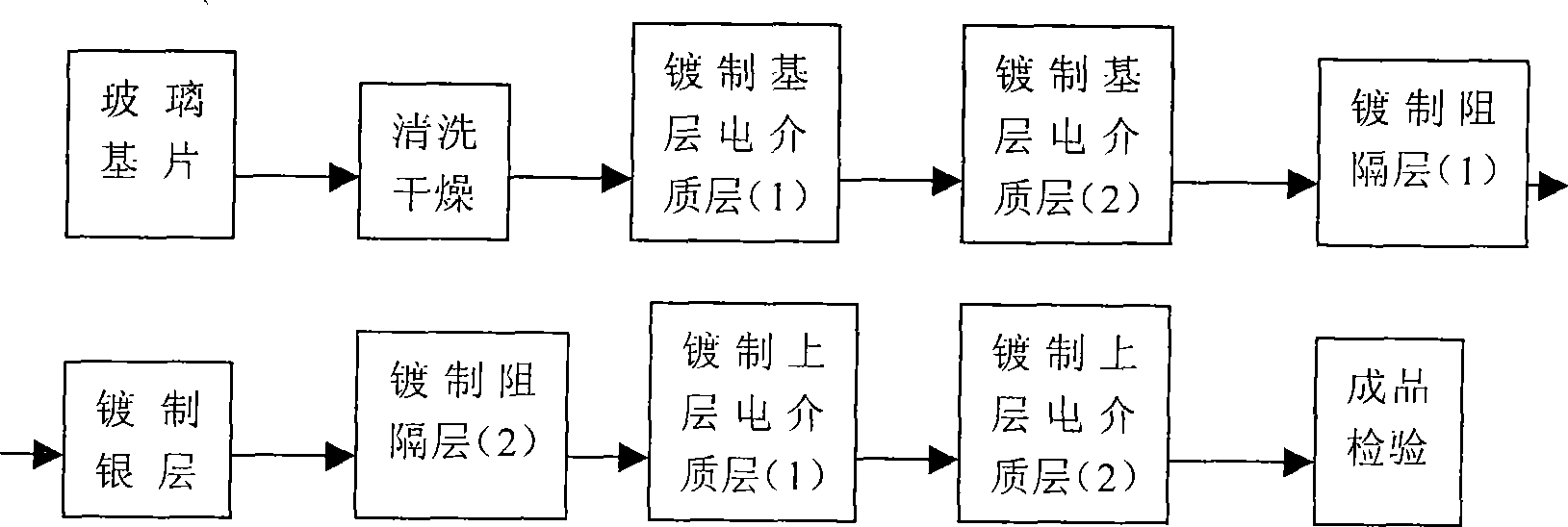

Low radiation glass capable of being post-treated and its production process

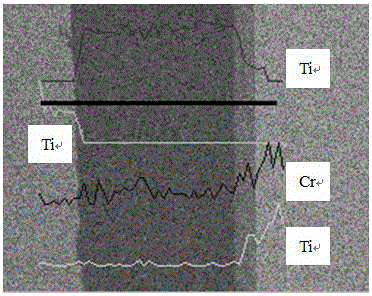

InactiveCN101066845AOptical performance is stableRich in colorVacuum evaporation coatingSputtering coatingSilicon nitrideLow emissivity

The low radiation glass capable of being post-treated is prepared through cleaning glass substrate, drying and coating film, and features that the vacuum magnetically controlled sputtered film on the glass substrate includes Si3N4 film, ZnSnOx film, NiCrOx film, Ag film, NiCrOx film, ZnSnO film and Si3N4 film successively coated. The coated glass has low radiation, stable optical performance, different colors, capacity of being toughened and / or bent at high temperature up to 700 deg.c, and capacity of being cut and treated in other modes.

Owner:SHENZHEN CSG APPLIED TECH CO LTD

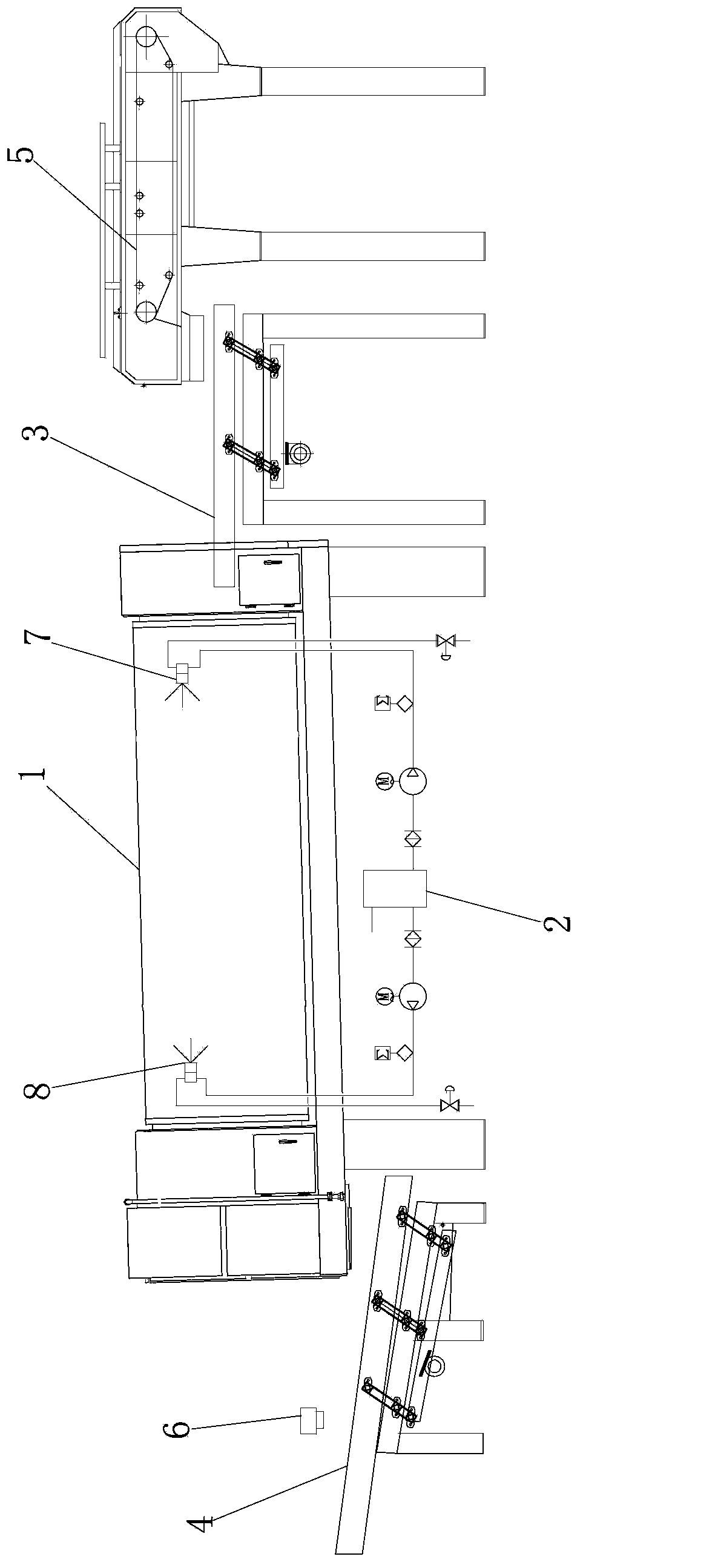

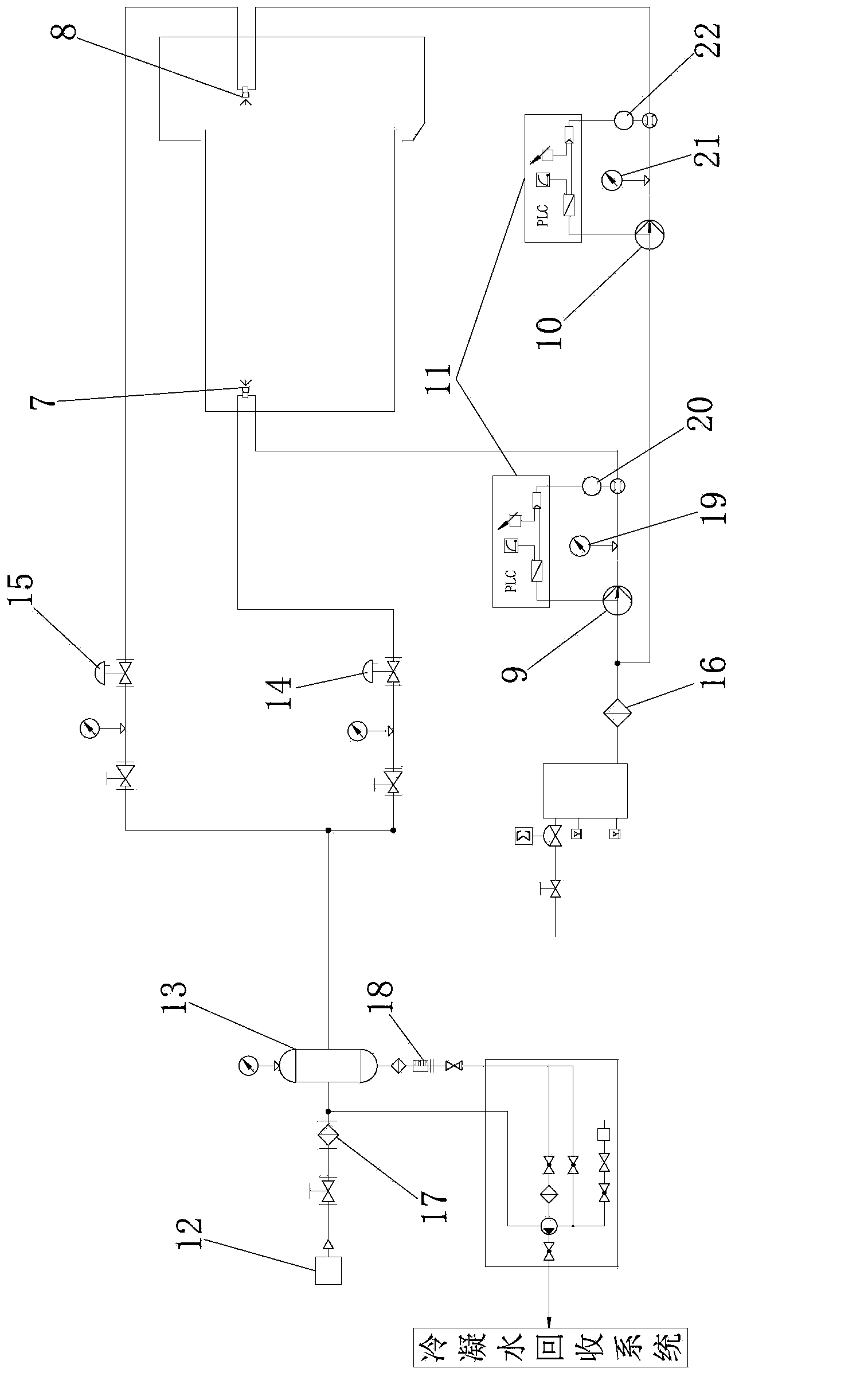

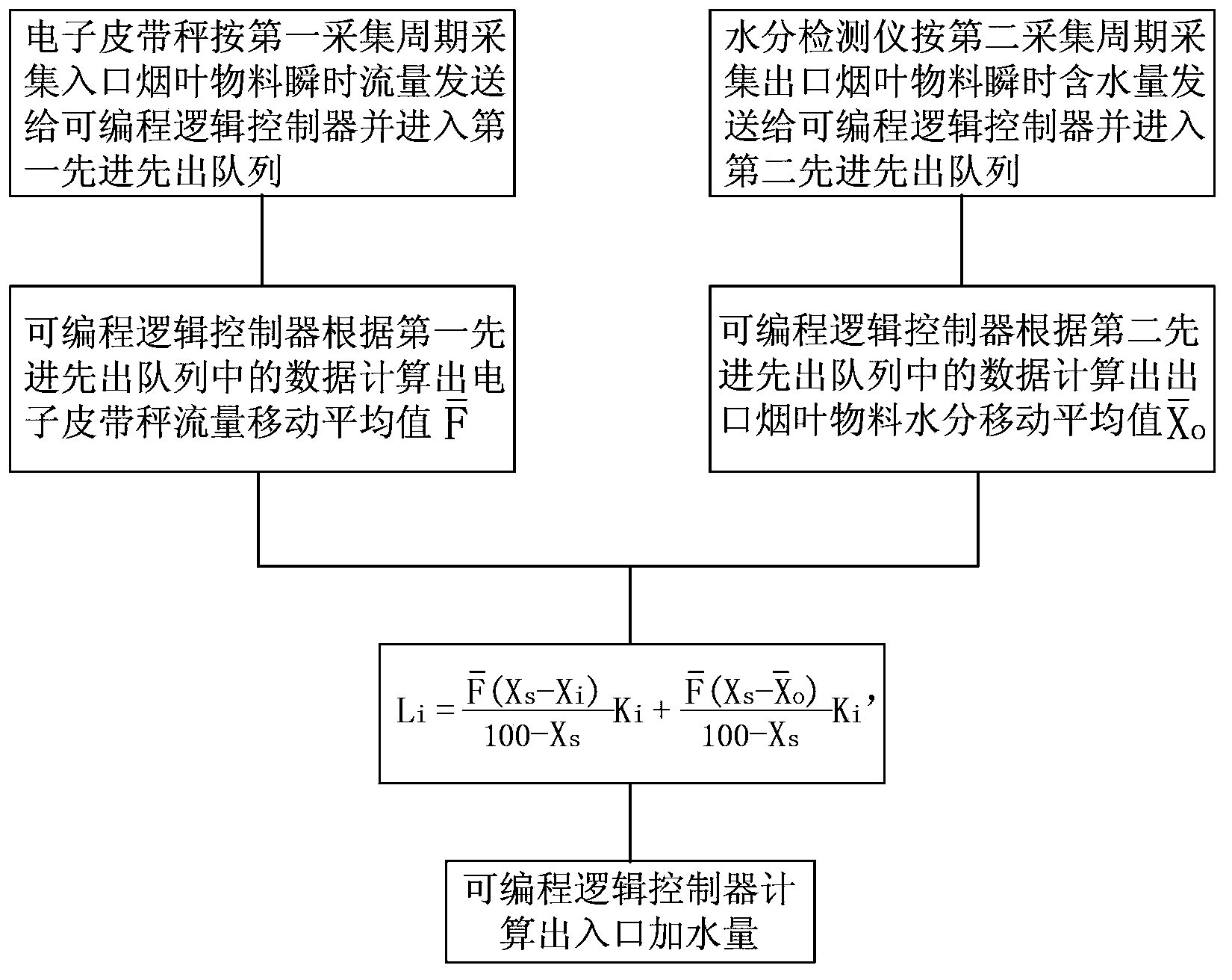

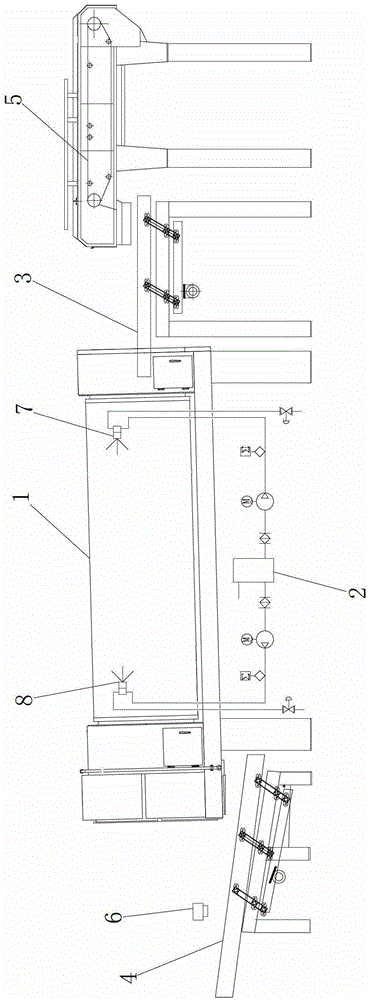

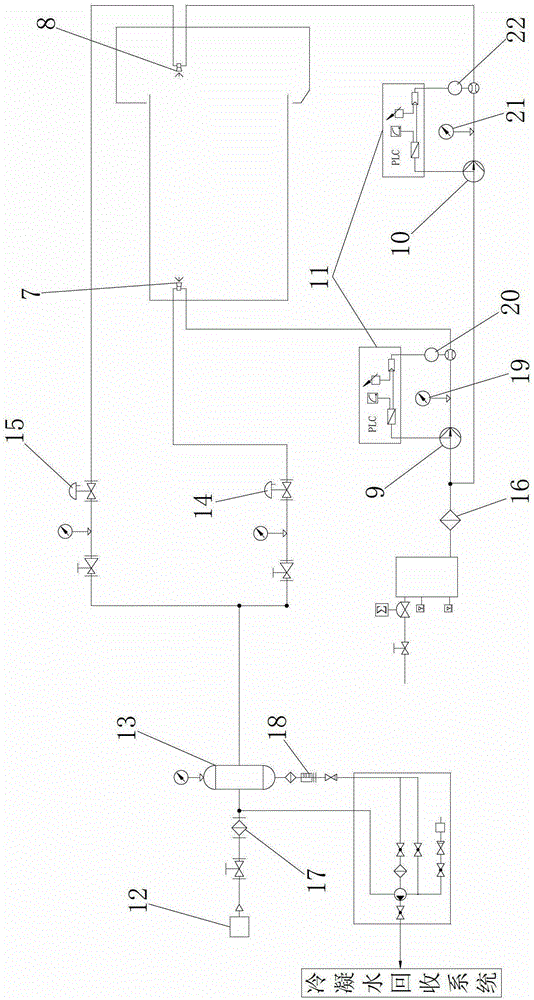

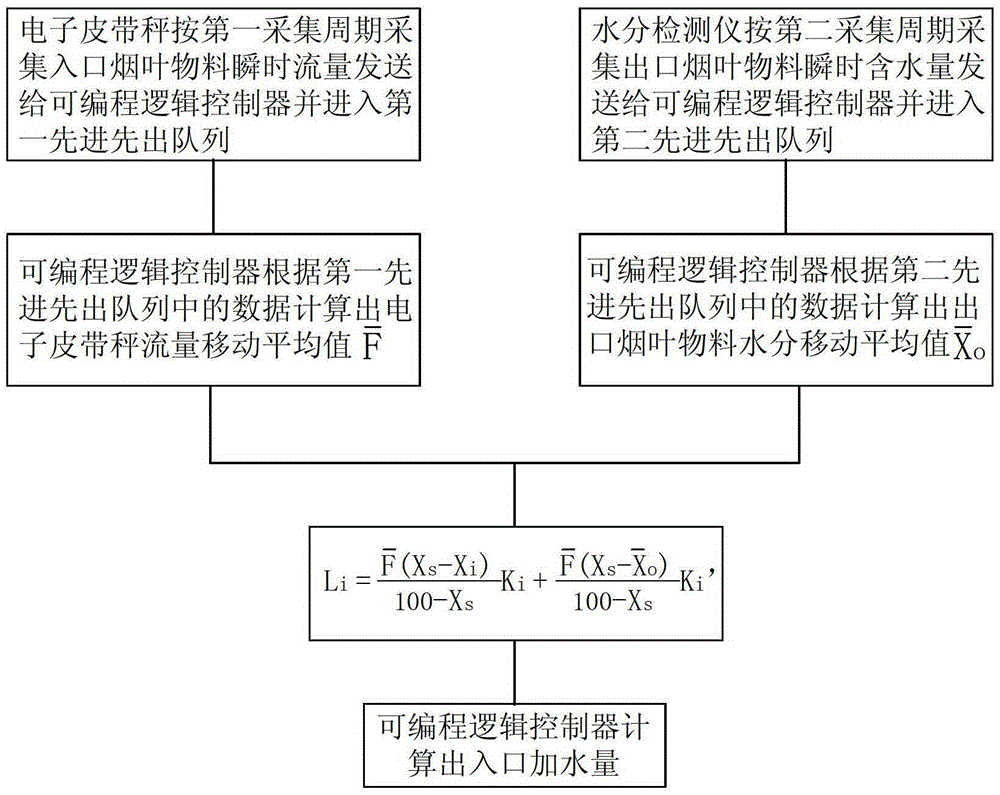

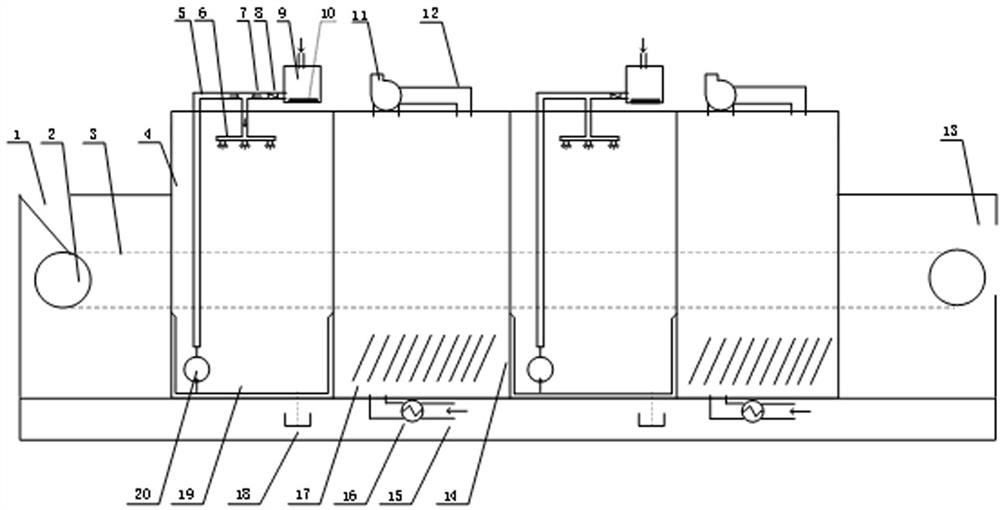

Tobacco leaf loosening and dampening device and water adding control method thereof

ActiveCN103844337AImprove stabilityMeet the requirements of subsequent processingTobacco preparationGear pumpProgrammable logic controller

The invention discloses a tobacco leaf loosening and dampening device and a water adding control method thereof. The tobacco leaf loosening and dampening device comprises a dampening rotary drum, a water tank, an inlet vibration groove, an outlet vibration groove, an electronic belt scale, a moisture detector, a dampening rotary drum inlet water adding system, a dampening rotary drum outlet water adding system and a programmable logic controller. The dampening rotary drum inlet water adding system comprises a first double-medium atomizing nozzle and a first gear pump, and the dampening rotary drum outlet water adding system comprises a second double-medium atomizing nozzle and a second gear pump. The water adding control method comprises an inlet water adding amount control method and an outlet water adding amount control method. By the tobacco leaf loosening and dampening device and the water adding control method, tobacco leaf moisture fluctuation is effectively reduced, the tobacco leaf material moisture stability is improved through tobacco leaf material moisture preliminary adjustment and quick feedback adjustment, and the stability of the inherent quality of follow-up cigarette products is improved.

Owner:CHINA TOBACCO SHANDONG IND

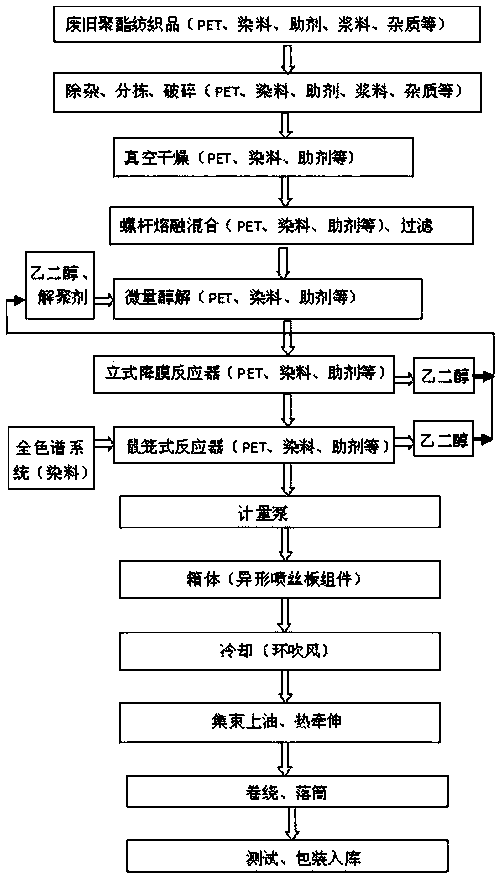

Method for producing high-performance regenerated polyester colored special-shaped filaments on basis of waste polyester textile products

InactiveCN108396392AEfficient removal of impuritiesSimple processDrying solid materials without heatMelt spinning methodsDepolymerizationHigh energy

The invention relates to a method for producing high-performance regenerated polyester colored special-shaped filaments on the basis of waste polyester textile products. By the aid of the method, theproblems of high energy consumption and secondary pollution due to impurity removing, cleaning, drying and the like in existing waste textile product recycling procedures can be solved. The method includes steps of 1), pretreating the waste regenerated polyester textile products; 2), carrying out vacuum drying; 3), carrying out screw melting extrusion, micro-depolymerization, conditioning viscosity increasing, full-color-spectrum color matching and toning, spinning manifold treatment, circular air blowing cooling, bundling oiling and winding doffing on dried polyester textile products to obtain the high-performance regenerated polyester colored special-shaped filaments. The method has the advantages that the problems of high energy consumption and secondary pollution due to impurity removing, cleaning, drying and the like in the waste textile product recycling procedures can be solved by the aid of the method; the monofilament denier of fibers obtained by the aid of the method ranges from 1.0 dtex to 3.0 dtex; the yarn evenness of the fibers is lower than or equal to 2.2%; the breaking strength of the fibers is higher than or equal to 4.0 cN / dtex; the elongation at break ranges from 15% to 25%.

Owner:ZHEJIANG HAILI ENVIRONMENTAL TECH CO LTD

Preparation method of pseudo-boehmite and porous alumina

ActiveCN102910656AKeep dryLow costCatalyst carriersAluminium oxide/hydroxide preparationEnergy consumptionAluminium salts

The invention provides a preparation method of pseudo-boehmite and porous alumina. The weight content of pseudo-boehmite is 30%-50% that of alumina. The preparation method of pseudo-boehmite comprises the steps of (1) performing neutralized gelatinizing reaction on an aluminium salt solution and a precipitating agent; (2) filtering and recovering solid products of the gelatinizing reaction; (3) drying the solid product obtained by filtering, wherein the dried material is pseudo-boehmite with the weight content being 30-50% that of alumina; and shaping, drying and roasting the obtained pseudo-boehmite to obtain porous alumina. The method simplifies the drying process in the preparation process of pseudo-boehmite, increases production efficiency, reduces production energy consumption, and further reduces the cost of catalysts. The porous alumina prepared by the method can be used as carriers for various hydrogenation catalysts.

Owner:CHINA PETROLEUM & CHEM CORP +1

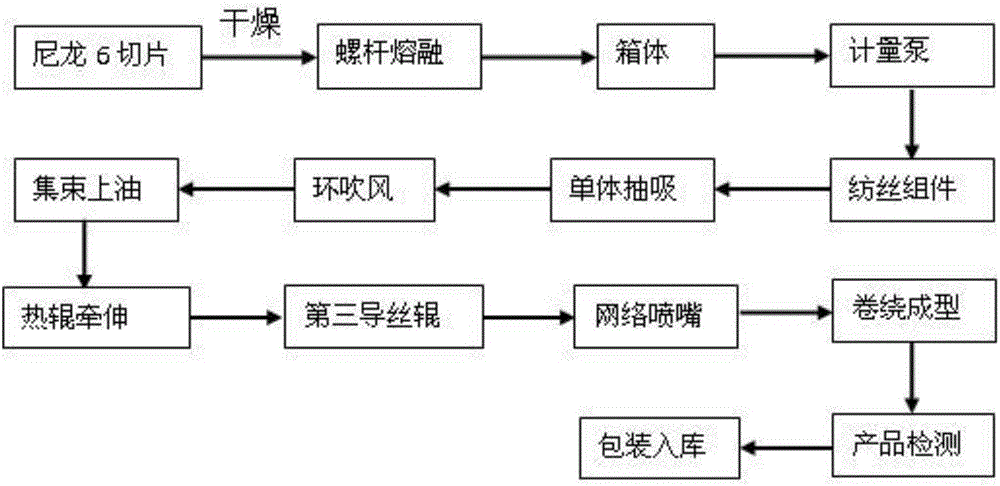

Ultra-coarse-denier flat nylon 6 filament and method for producing the same

InactiveCN104818538AStable productionImprove product qualityArtificial thread manufacturing machinesFilament/thread formingBreaking strengthFiber

The invention discloses a method for producing an ultra-coarse-denier flat nylon 6 filament. The producing method comprises the following steps of cutting the nylon 6 into pieces and conveying into a screw for heating and melting, extruding fondants into a box through the screw (including static and dynamic mixers); placing the fondants into a spinneret assembly through a metering pump, mixing and filtrating through different-size metal sands and then extruding by spinneret orifices. Through a monomer pumping device, filament bundles extruded by the spinneret orifices are wound into a filament barrel after performing circular blowing cooling, bundling oiling, air interlacing jet, heating roller sizing. The aperture of each spinneret orifice is in the range of 1.5mm-5.0mm*0.15mm-0.40mm, and the orifice depth is in the range of 0.5mm-1.5mm; according to the producing method, the flatness of the fiber is in the range of 4.0-9.0. The production process is relatively steady, the produced ultra-coarse-denier flat nylon 6 filament is good in quality, and the flatness, breaking strength, breaking elongation and oil percentage of the filament can meet subsequent processing requirements, and thus the filament is a novel differential nylon 6 fiber with a high additional value.

Owner:ZHEJIANG MESBON CHEM FIBER +1

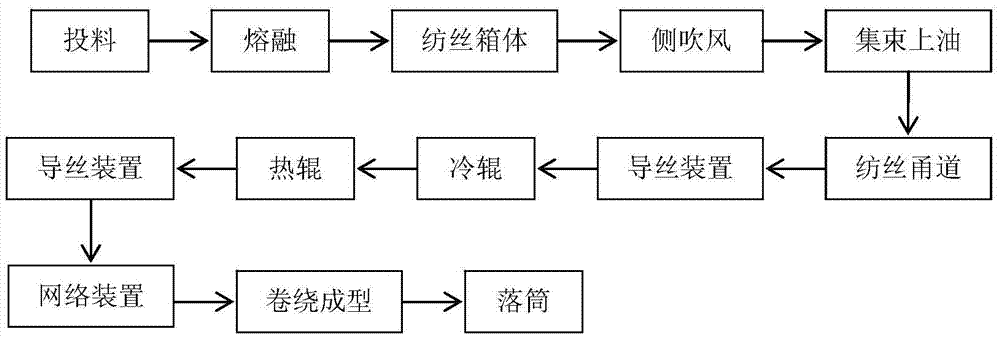

Imitation rabbit hair chinlon 6 fiber and production method of imitation rabbit hair chinlon 6 fiber

InactiveCN105442071AReasonable designMelt fine flow forming effect is goodMelt spinning methodsFilament-forming treatmentFinenessRelative viscosity

The invention relates to an imitation rabbit hair chinlon 6 fiber and a production method of the imitation rabbit hair chinlon 6 fiber. Fiber-stage chinlon 6 with the relative viscosity being 2.47+ / -0.02 and the moisture content being less than or equal to 500ppm are sliced and are put into a material cabin; the materials are heated to a fusion state by a screw extruder, and are fed into a spinning manifold through a flux distribution pipeline; the flux enters a spinning assembly in the spinning manifold, and is sprayed out through flat cross section spinning orifices; the spinning orifices are arranged in a mode of a linear shape; lateral blowing is adopted for cooling a flat cross section nascent fiber; the flux streamlet is solidified into a fiber in high-speed movement; the cooled fiber beams are oiled and then enter a spinning passage; the silk beams complete the winding forming on a winding head by a spinning-stretching one-step method after passing through a cold roller, a hot roller, a net device and a tensioning roller. The imitation rabbit hair chinlon 6 fiber has the advantages that the flatness degree is 6.0 to 10.0, the thread density is 1.5 to 9D; a product has the characteristics of softness and fineness; the handfeel and the luster are like those of the rabbit hair; meanwhile, the excellent fluffiness, dirt resistance and anti-pilling performance are realized.

Owner:CHANGLE LIHENG POLYAMIDE TECH

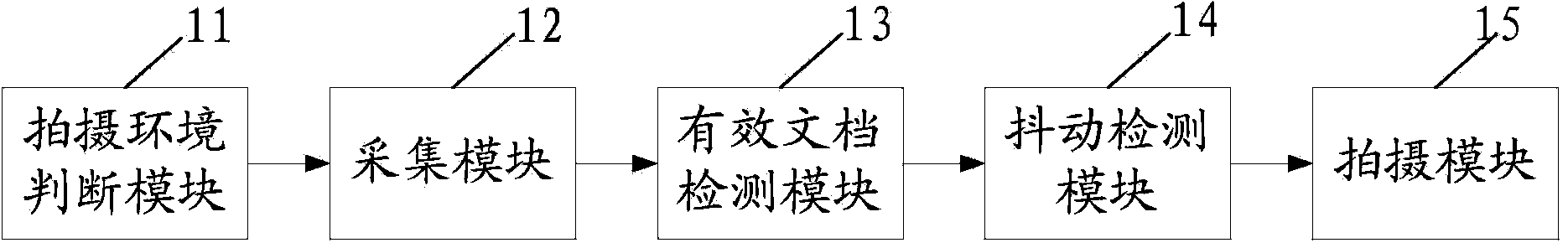

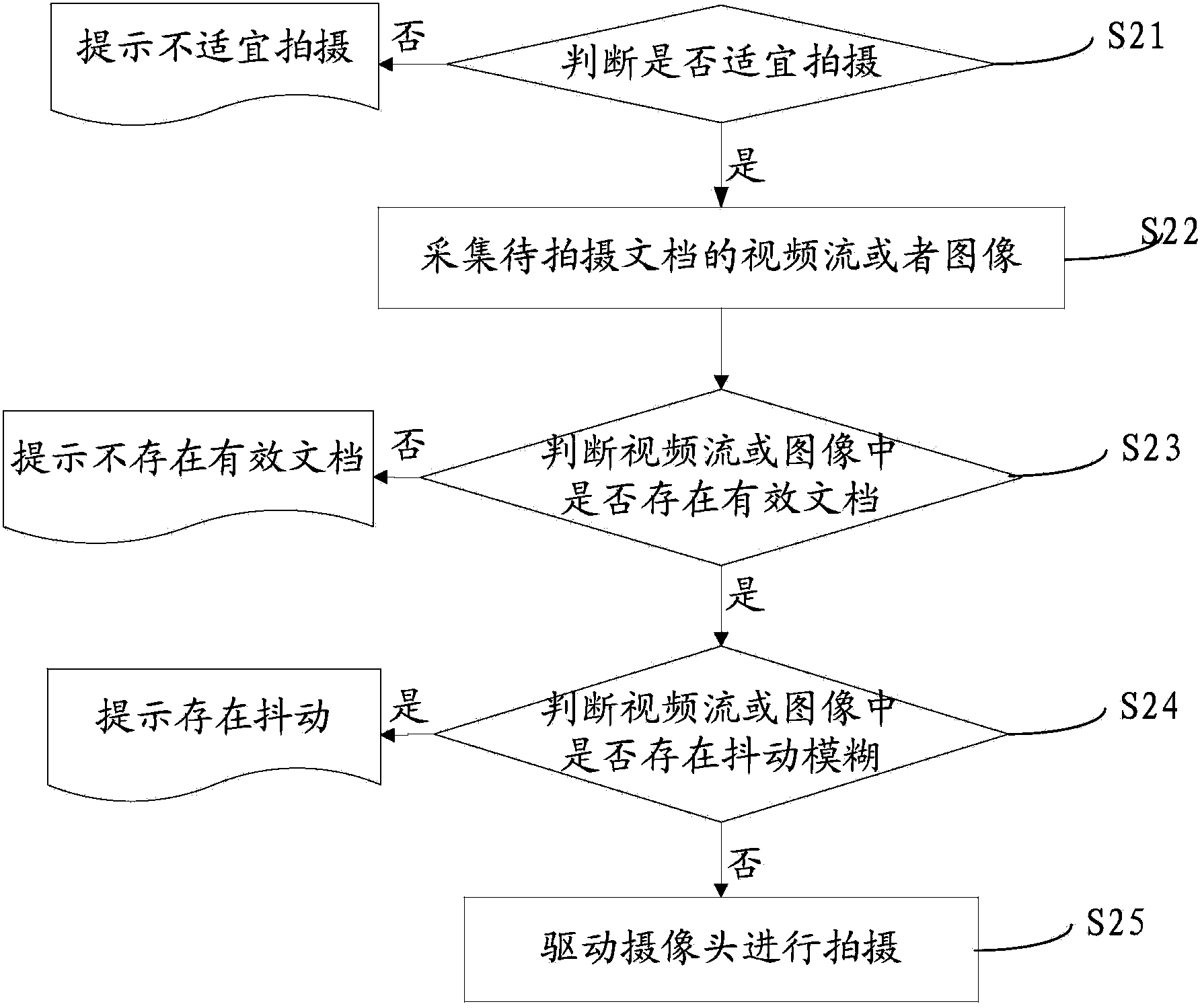

Method and system for shooting document image automatically

InactiveCN103455809AMeet the requirements of subsequent processingRealize automatic shootingTelevision system detailsCharacter and pattern recognitionComputer graphics (images)Autofocus

The invention relates to a method and system for shooting a document image automatically, and belongs to the field of image shooting. In the prior art, images are acquired mostly in a manual mode, and shot document images cannot easily meet the requirement of follow-up processing. According to the method and system, firstly, a camera is switched on to obtain current parameters, whether a current environment is suitable for shooting is judged, and the camera is used for collecting video streams or the images of a document to be shot if the current environment is suitable for shooting; secondly, whether an effective document exists in the video streams or the images is judged; thirdly, whether a jittering blur exists in the video streams or the images is judged; lastly, the camera is driven to conduct automatic focusing, the shooting of the document to be shot is completed, and the document image is obtained. When the method and system are used for shooting the document image, whether the shooting environment meets requirements, whether the effective document exists in the shooting process, and whether jittering exists in the shooting process can be detected automatically, and the document image can be obtained automatically.

Owner:FOUNDER INTERNATIONAL CO LTD +1

Method for removing metal from hydrocarbon oil using acrylic acid - acrylic ester copolymers

InactiveCN1521237AMitigate the impact of further processingMeet the requirements of subsequent processingHydrocarbon oils refiningDemulsifierCalcium content

The process of eliminating metal from hydrocarbon oil with acrylic acid-acrylate copolymer includes mixing the acrylic acid-acrylate copolymer with water injecting demulsifier and raw oil at 30-200 deg.c to make metal in hydrocarbon oil generate water soluble compound dissolved in water, and oil-water separation to eliminate metal from hydrocarbon oil. The acrylic acid-acrylate copolymer has molecular weight of 1000-50000, and molar ratio between acrylic acid structure units and acrylate structure units of 0.1-20. The copolymer consumption is 0.5-5 times, preferably 1.0-3.0 times, the total calcium weight in hydrocarbon oil. The process has the features of less copolymer consumption and high elimination efficiency, and may be used for hydrocarbon oil in excessive calcium content.

Owner:CHINA PETROLEUM & CHEM CORP +1

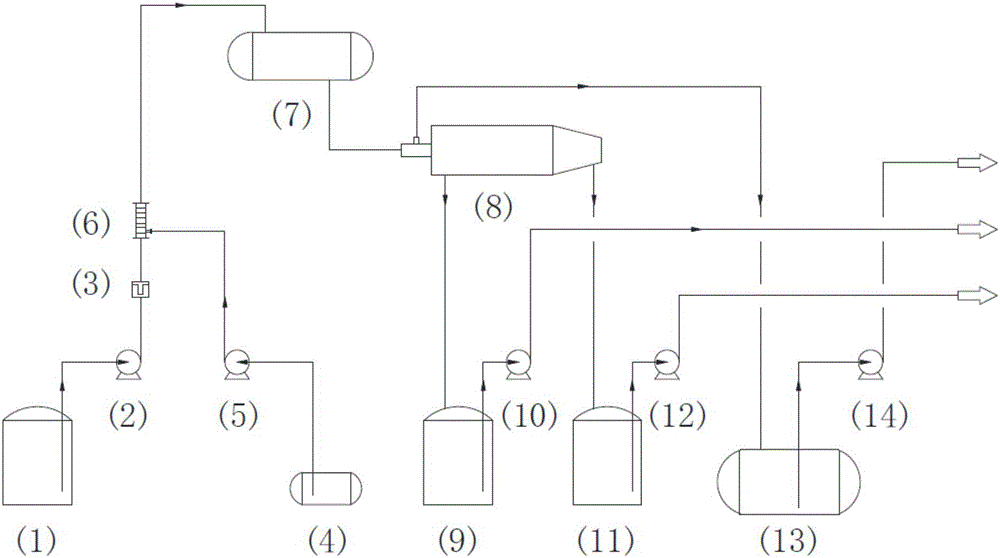

Coal tar pretreatment combined system and method

PendingCN106118703ATo achieve the purpose of dehydrationBreak the patternTar working-up by water removalDemulsifierSlag

The invention discloses a coal tar pretreatment combined system and method. The coal tar pretreatment combined system comprises a coal tar tank, a demulsifier tank, a separating and feeding buffer tank, a three-phase separator, a sewage tank, a slag tank, and an oil tank. The coal tar tank is connected with the separating and feeding tank through a coal tar pump, an automatic backwashing filter and a static mixer, and the demulsifier tank is connected with the static mixer through a demulsifier pump. Before separation, by adding the demulsifier, small-particle-size hydrone can be combined under the action of the demulsifier. Meanwhile, small-particle-size oil molecules can be combined to thereby break up the pattern of oil in water and water in oil thoroughly and release emulsified water from oil thoroughly. At this time, coal tar can be centrifugally separated, oil and water can be well separated and the purpose for dehydrated coal tar can be achieved.

Owner:BEIJING HUAFU ENG

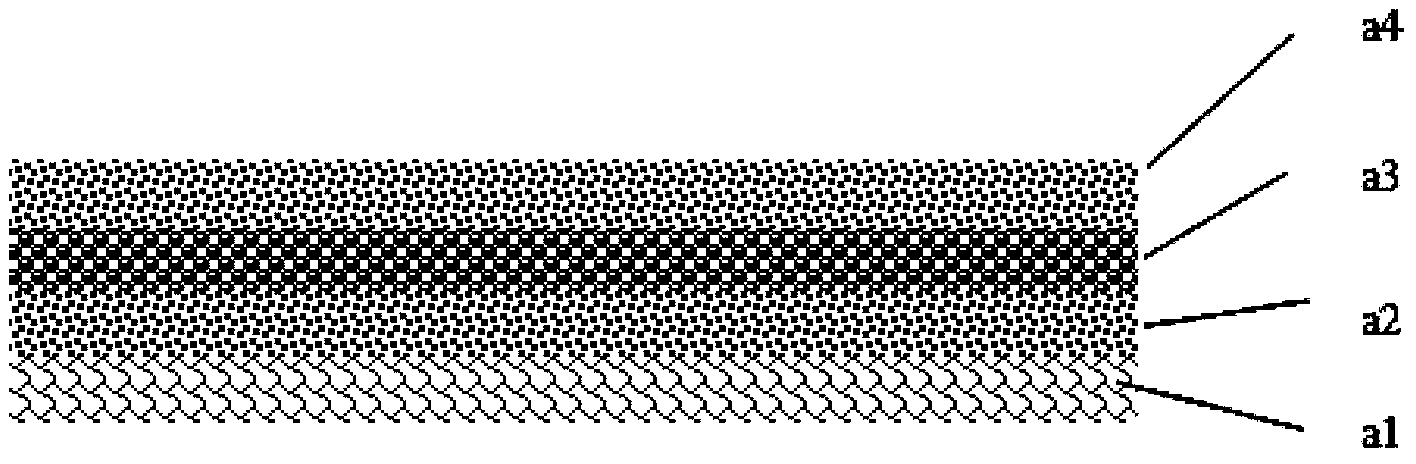

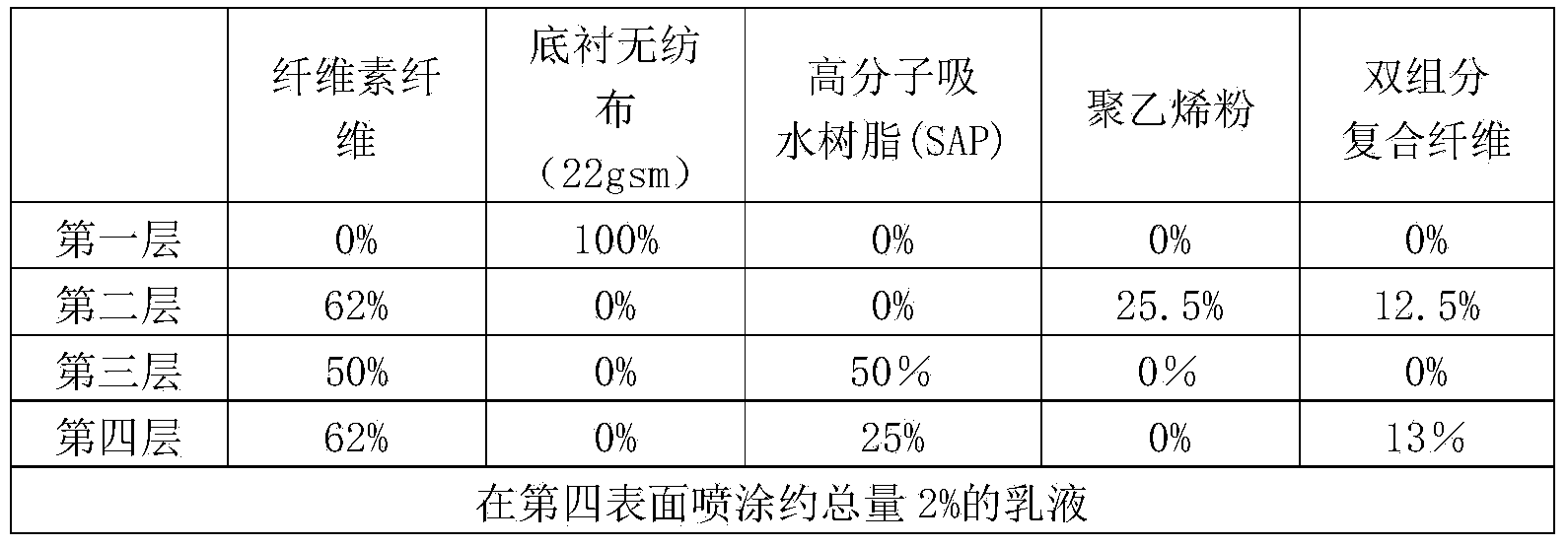

Composite dustless paper and production process and application thereof

ActiveCN103006391BNot easy to layerMeet the requirements of subsequent processingLayered productsAbsorbent padsPolymer scienceCellulose fiber

The invention relates to composite dustless paper and production process and application thereof. The composite dustless paper has the structure that a first layer is a lining layer and is made from a non-woven material; a second layer comprises a cellulosic fiber, a bonding material and a high molecular absorbing material; a third layer comprises a high molecular water-absorbing material, a cellulosic fiber and a selectively added bicomponent composite material; a fourth layer comprises a cellulosic fiber, a bicomponent composite fiber and a high molecular water-absorbing material; and an emulsion can be selectively sprayed onto the surface of the lining layer and / or the fourth layer. The composite dustless paper is continuously produced in a forming process by an air flow web-forming manufacturing process. The composite dustless paper is applied to disposable hygienic products including the hygienic products for women, adult incontinence products and paper diapers, food pads, pet pads and the like. By the composite dustless paper, the application variety of other materials to disposable hygienic product production is reduced, a supply chain and a production process are simplified, and the efficiency is improved.

Owner:FITESA CHINA AIRLAID

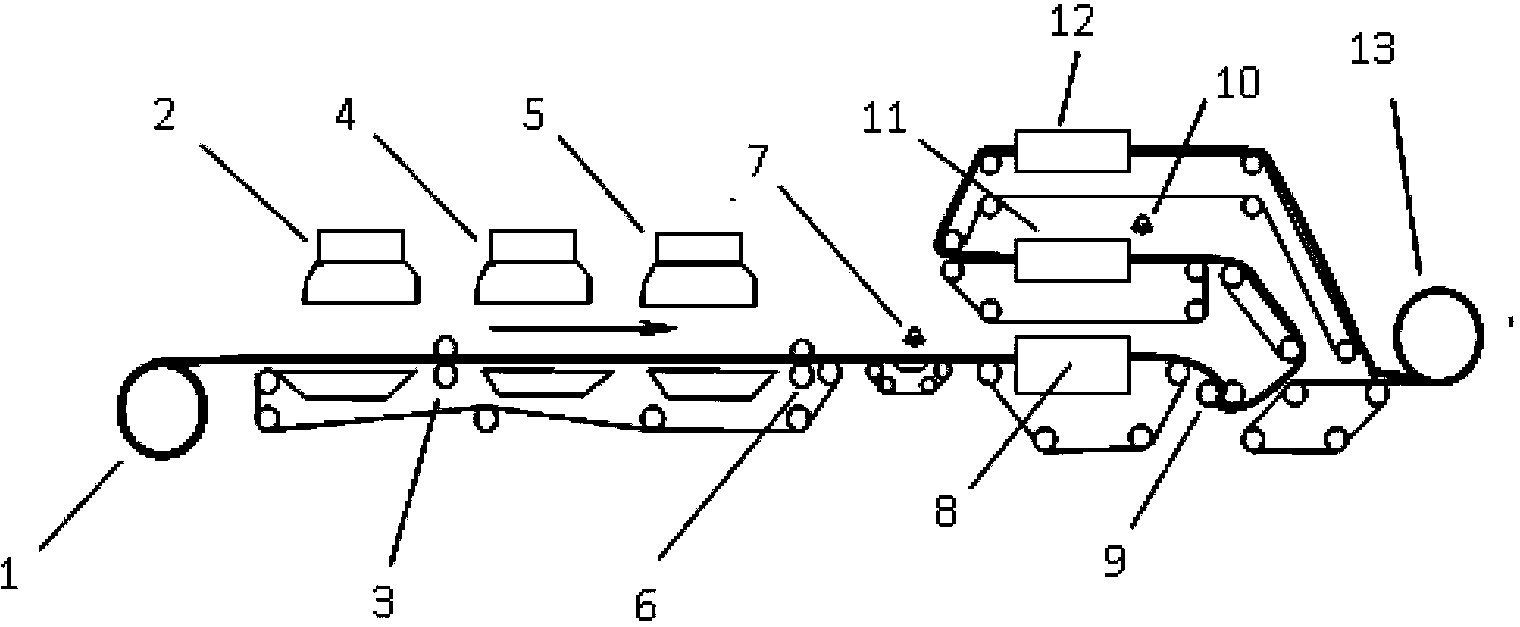

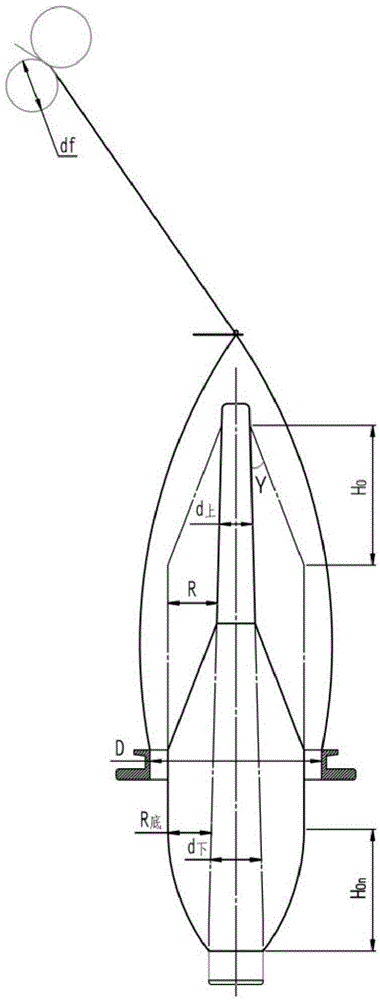

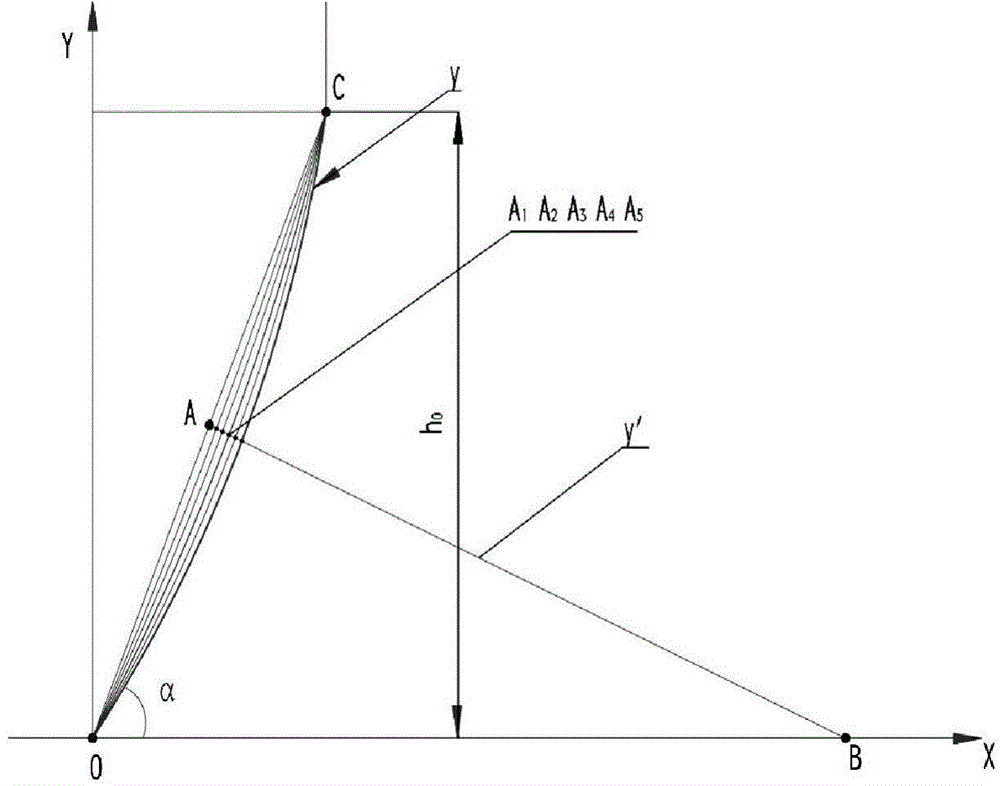

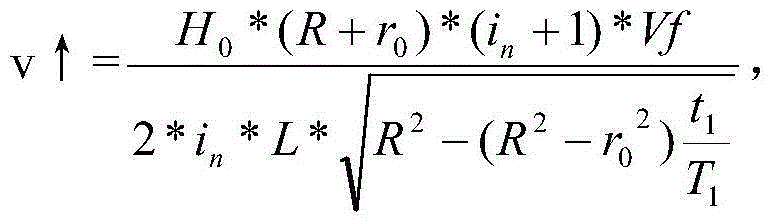

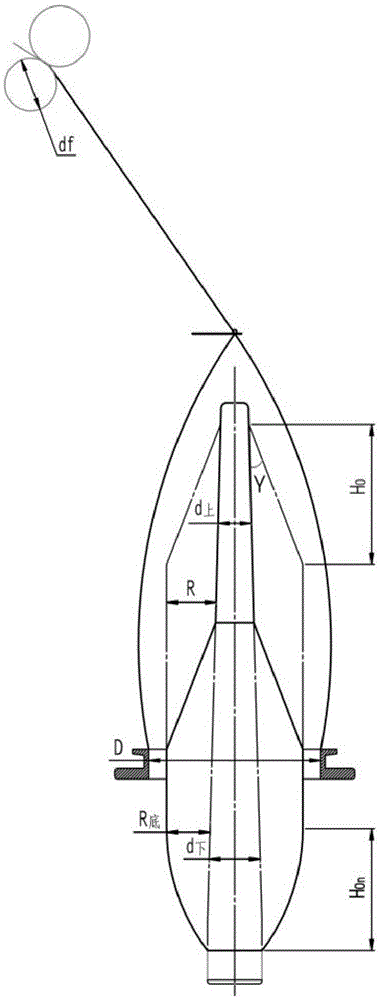

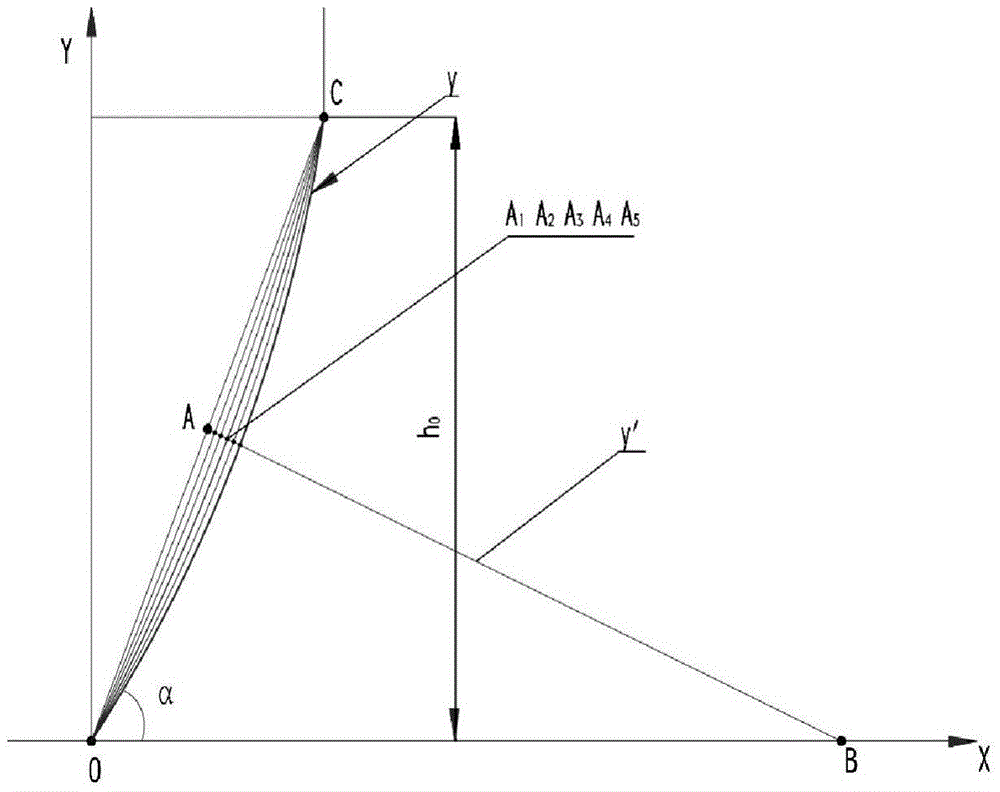

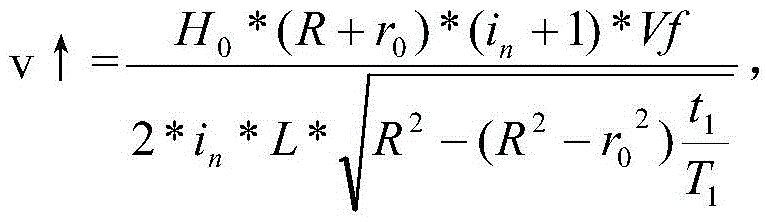

Spinning frame tube electronic forming method

InactiveCN104153060ALarge capacityGood lookingContinuous wound-up machinesMathematical modelConductor Coil

Provided is a spinning frame tube electronic forming method. A conical cross winding mode is adopted for a tube, in the winding process, a steel collar plate is independently transmitted by an independent motor, and the steel collar plate repeatedly conducts a plurality of short stroke lifting movements upwards from the bottom winding position of the tube; through the establishment of a preference mathematic model, the speed controllable and position controllable transmission mode of the steel collar plate is completed, and thus the equal thread pitch winding and leveling up arrangement of the tube on a forming conical surface are achieved, and the internal forming structure of the tube is controlled according to the continuously developing technical state of a spring frame through the reasonable selecting optimization of parameters in the mathematic model. In any short stroke lifting process, the proportion of ascending time and descending time can be adjusted as needed. The spinning frame tube electronic forming method can achieve the technical purpose of meeting the forming requirements of different spinning varieties. A tube bottom forming section is further arranged, the tube with the large volume and good appearance forming is formed, the requirement for automatic winding high speed unwinding of a subsequent procedure can be met, and the production efficiency is improved.

Owner:PACIFIC MECHATRONIC GRP

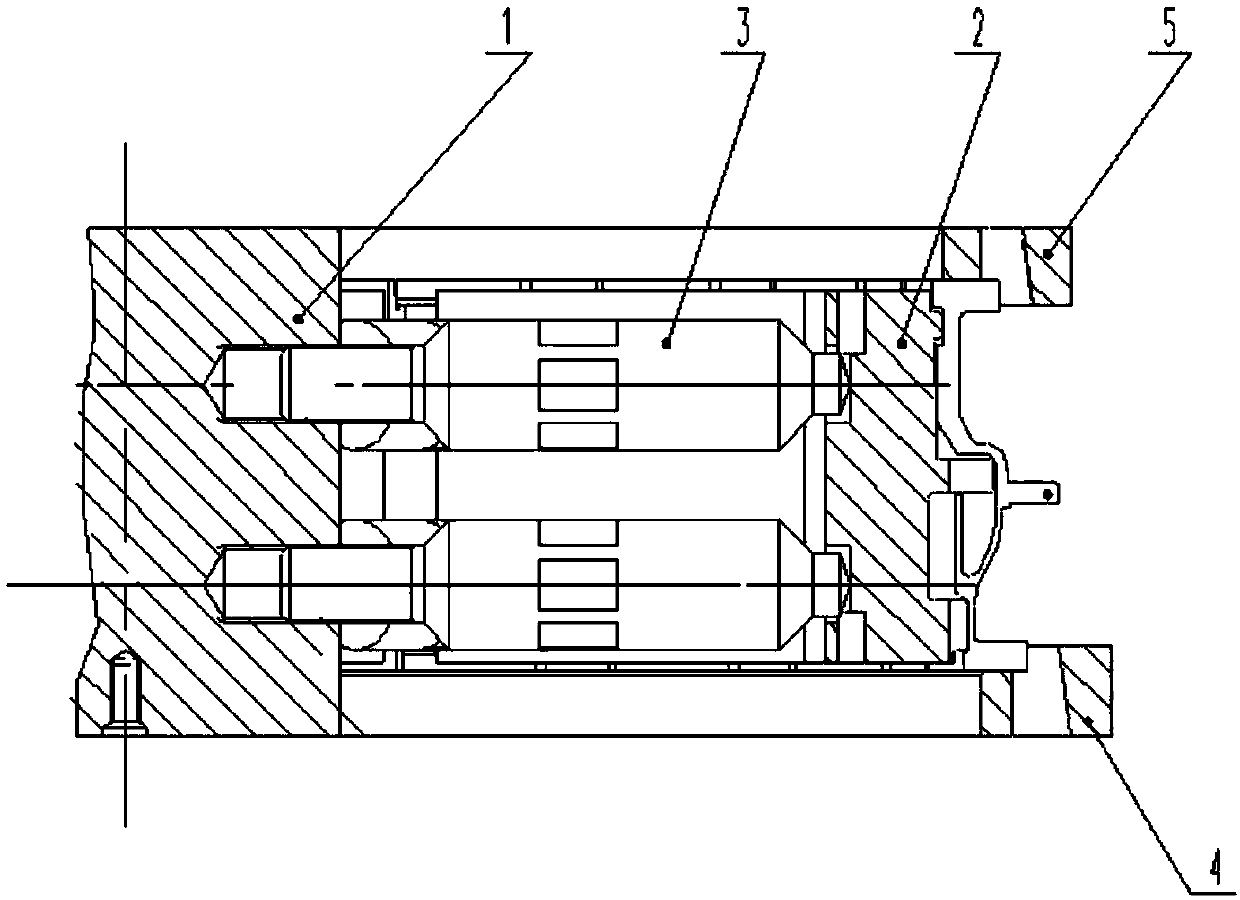

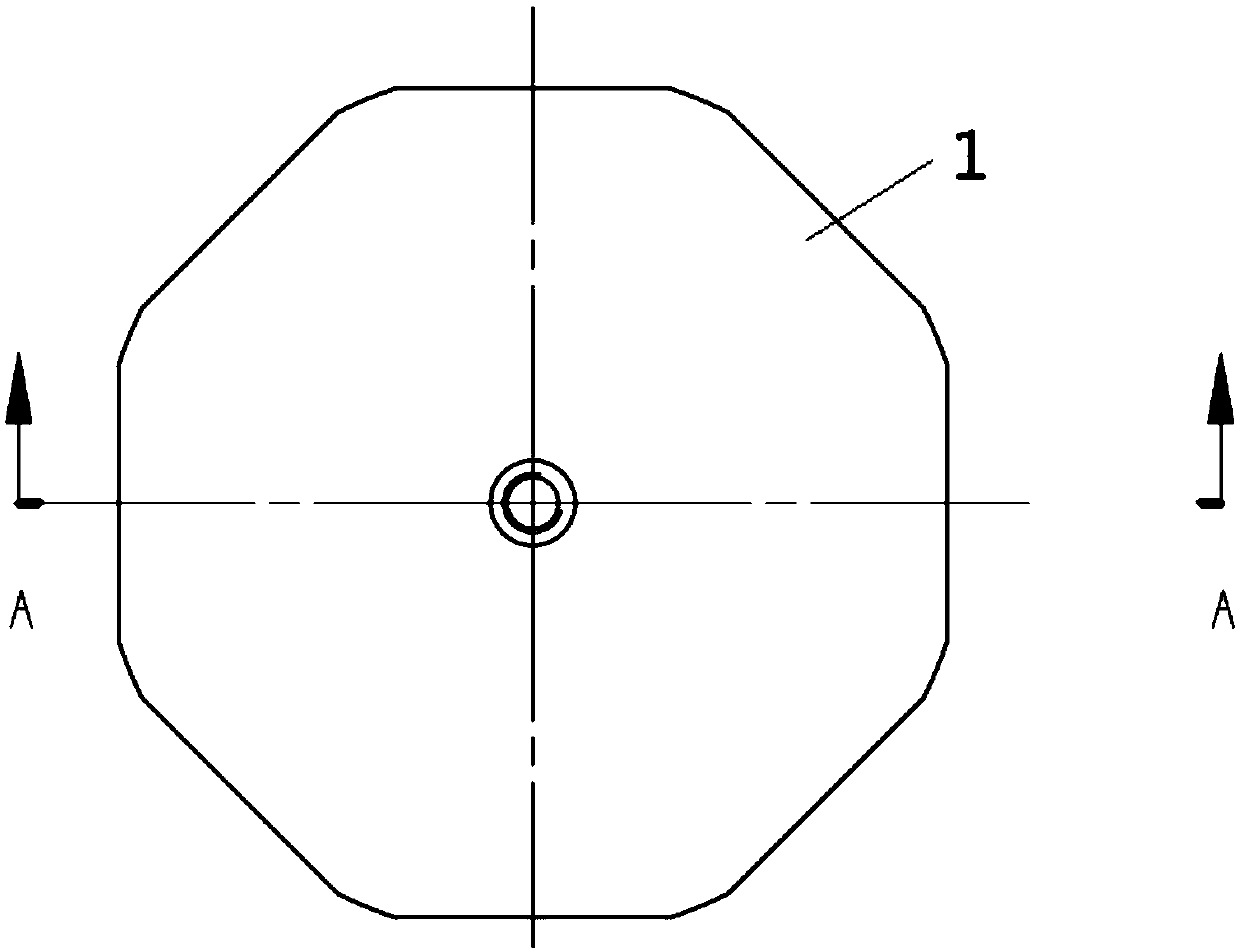

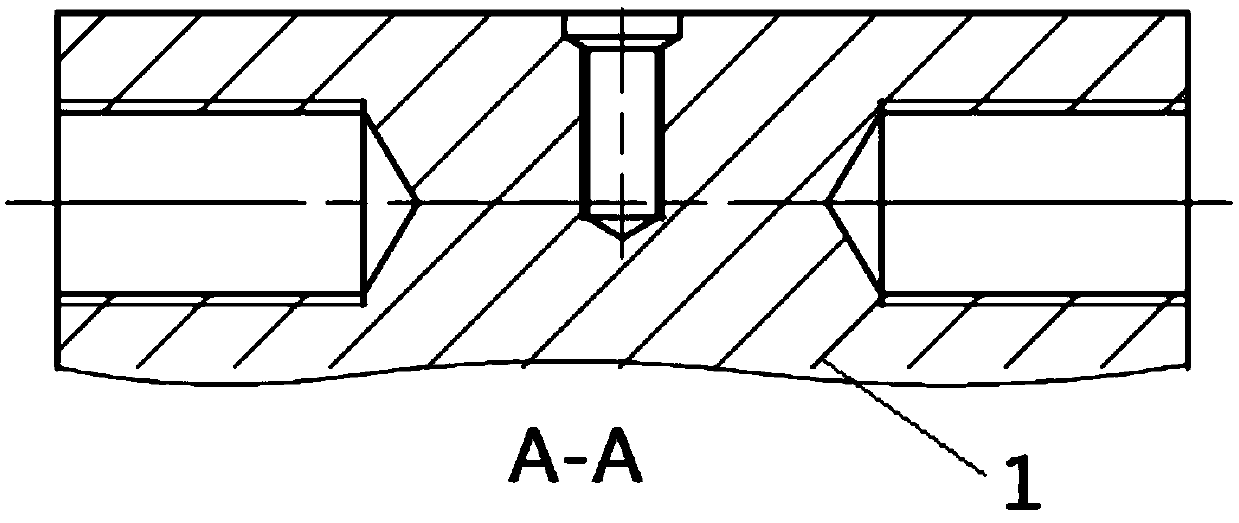

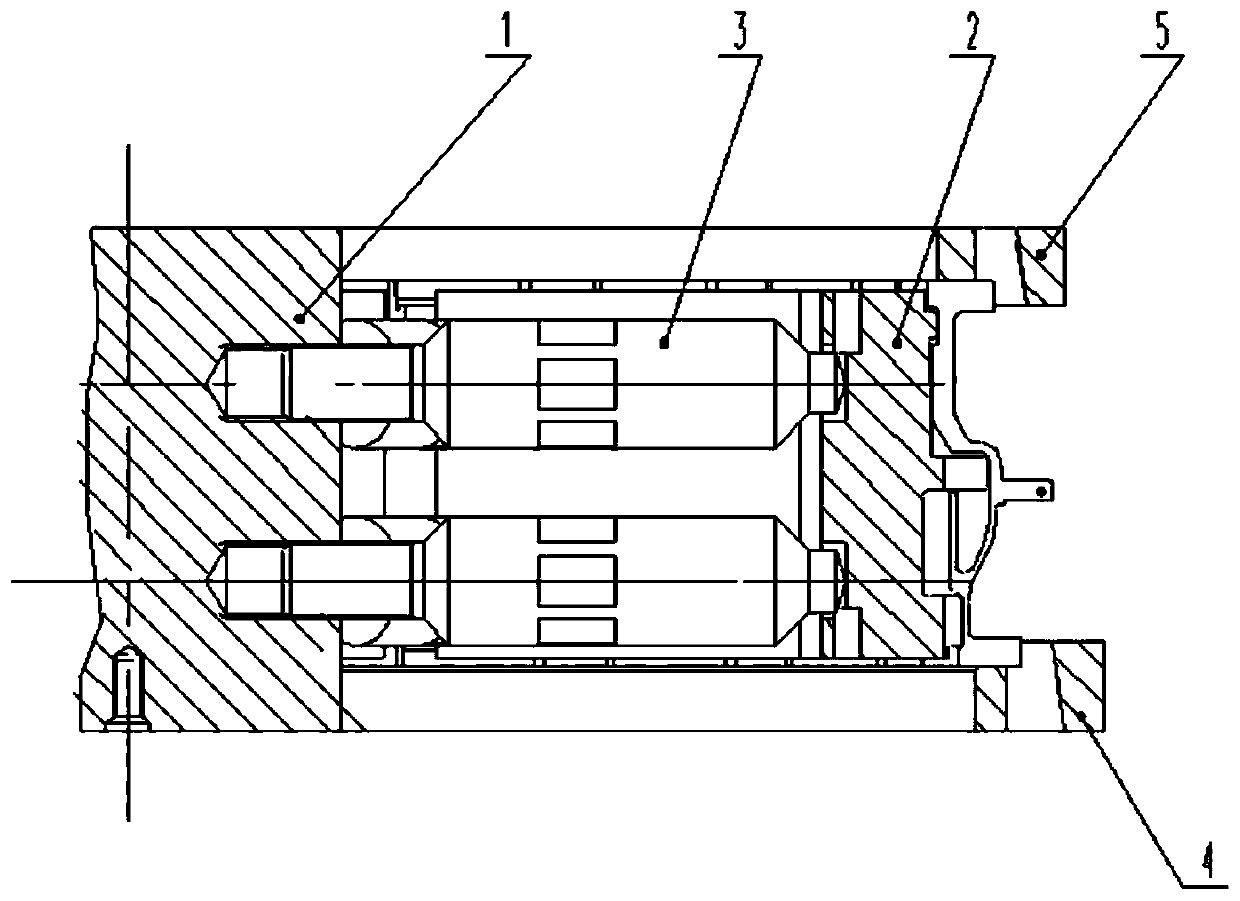

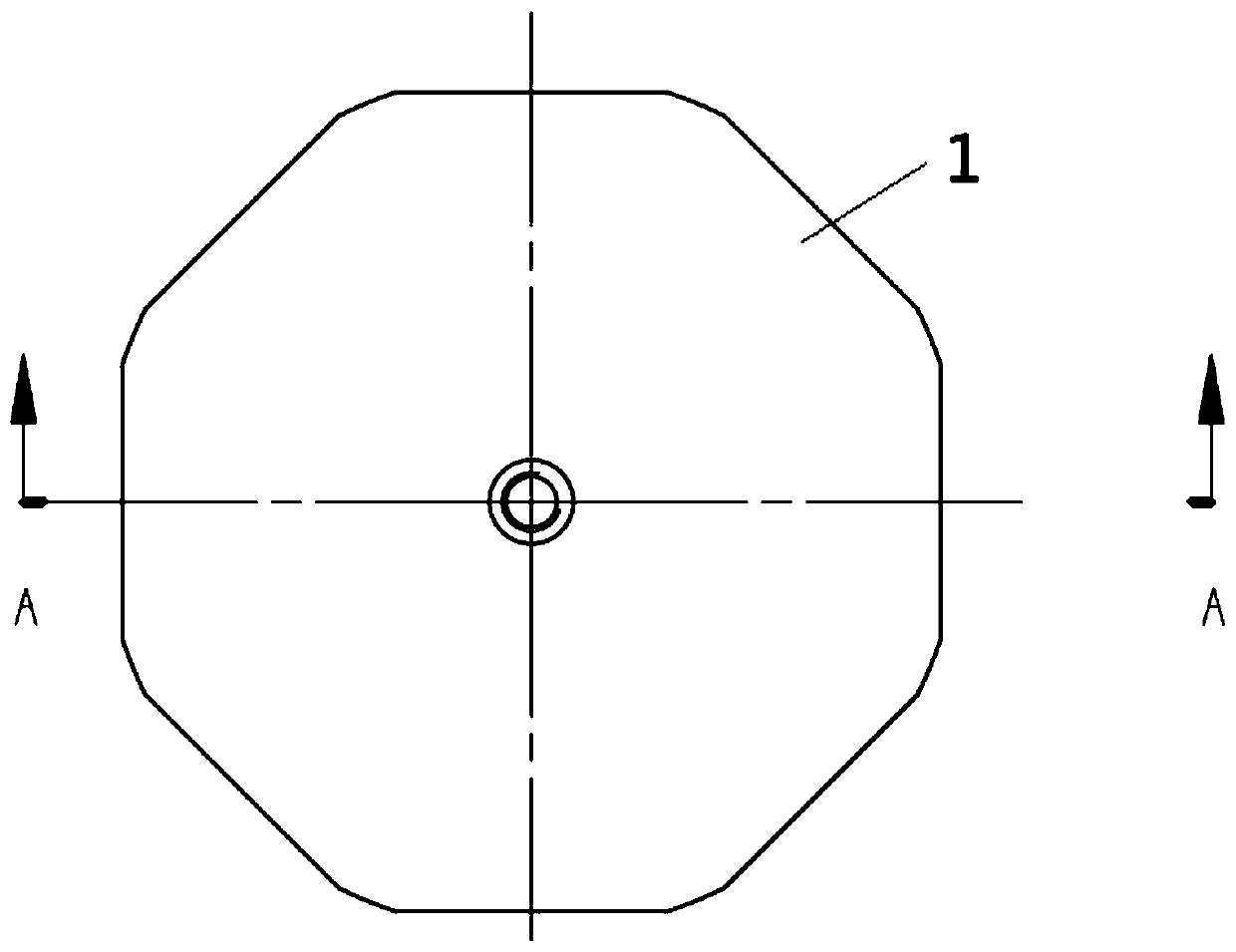

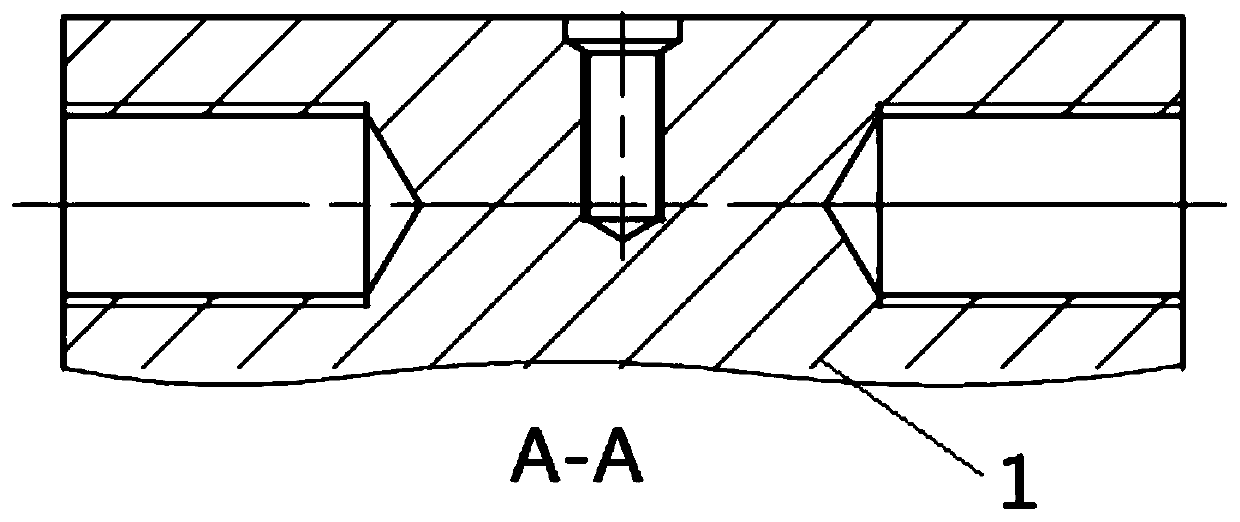

Shape correcting device of high temperature alloy split-opened casing and correcting method of shape correcting device

The invention discloses a shape correcting device of a high temperature alloy split-opened casing. The shape correcting device comprises a first outer shape correcting ring and a second outer shape correcting ring; an annular stopping opening is formed in the inner side of each outer shape correcting ring, and the diameter of each annular stopping opening is the same as the theoretical outer diameter of the end surface of the casing subject to shape correcting; a plurality of wedge holes are formed in the end surface of each outer shape correcting ring in the circumferential direction evenly and penetrate through the annular stopping openings in the outer shape correcting rings, and the shape correcting device further includes wedge blocks matched with the wedge holes; and a supporting rodinner shape supporting is connected with a supporting block and a mandrel, the outer shape surface of the supporting block is consistent with the inner shape surface of the casing subject to shape correcting, and the supporting rod is arranged in the radial direction of the casing subject to shape correcting. The invention further discloses a shape correcting method of the split-opened casing. Through the combination of cold shape correcting and heat shape correcting of the split-opened casing, the problem that the design requirements are not met due to the fact that the ellipticity of the split-opened casing changes too much is solved, the fact that the ellipticity of the split-opened can meet the requirements of the subsequent processing is ensured, the difficulty of the subsequent processing process is simplified, the processing quality of the parts is improved, and the rejection rate is reduced.

Owner:AECC AVIATION POWER CO LTD

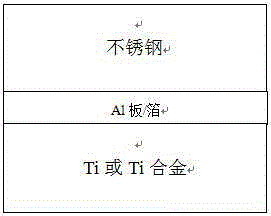

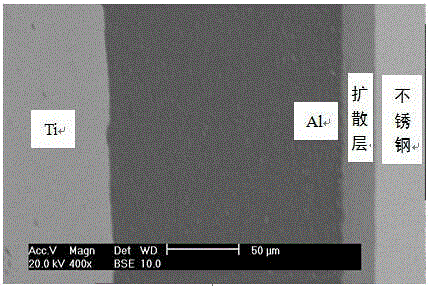

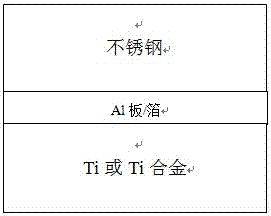

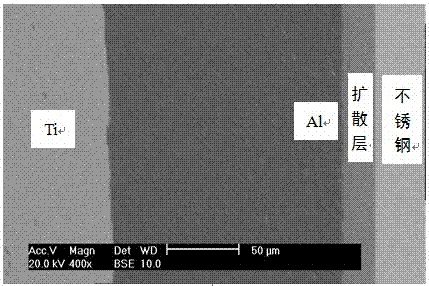

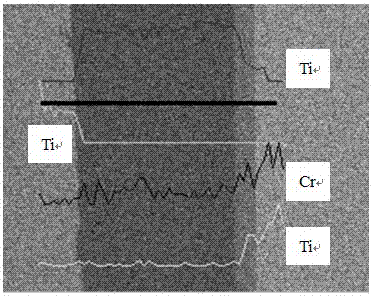

Preparing method for titanium-aluminum-stainless-steel composite plate

ActiveCN105172308AEasy to operateEasy to implementLaminationLamination apparatusSteel platesSheet steel

The invention discloses a preparing method for a titanium-aluminum-stainless-steel composite plate and belongs to field of composite material preparation. The method comprises the steps that a titanium plate, an aluminum plate / foil and a stainless steel plate are assembled, a titanium-aluminum-stainless-steel interlayer structure is formed and put into vacuum hot press equipment to be treated for 0.5-2 hours at the pressure of 1-4 MPa at 550-650 DEG C, and then cooling treatment is conduced to obtain the titanium-aluminum-stainless-steel composite plate. The preparing method is simple in operation and convenient to implement, a titanium / aluminum interface and an aluminum / stainless steel interface form metallurgical bonding through even dispersing, and the titanium-aluminum-stainless-steel composite plate is obtained.

Owner:KUNMING UNIV OF SCI & TECH

Process for demetalizating of hydrocarbon oil

InactiveCN1295303CProduce secondary pollutionReduce the impact of processingHydrocarbon oils refiningOil processingDemulsifier

A demetallating process for the hydrocarbon oil includes such steps as mixing the acetylacetone as demetalating agent with raw hydrocarbon oil, water and demulsifier, and oil-water separation. Its advantage is high effect to remove Ca, Mg, Fe, etc.

Owner:EAST CHINA UNIV OF SCI & TECH

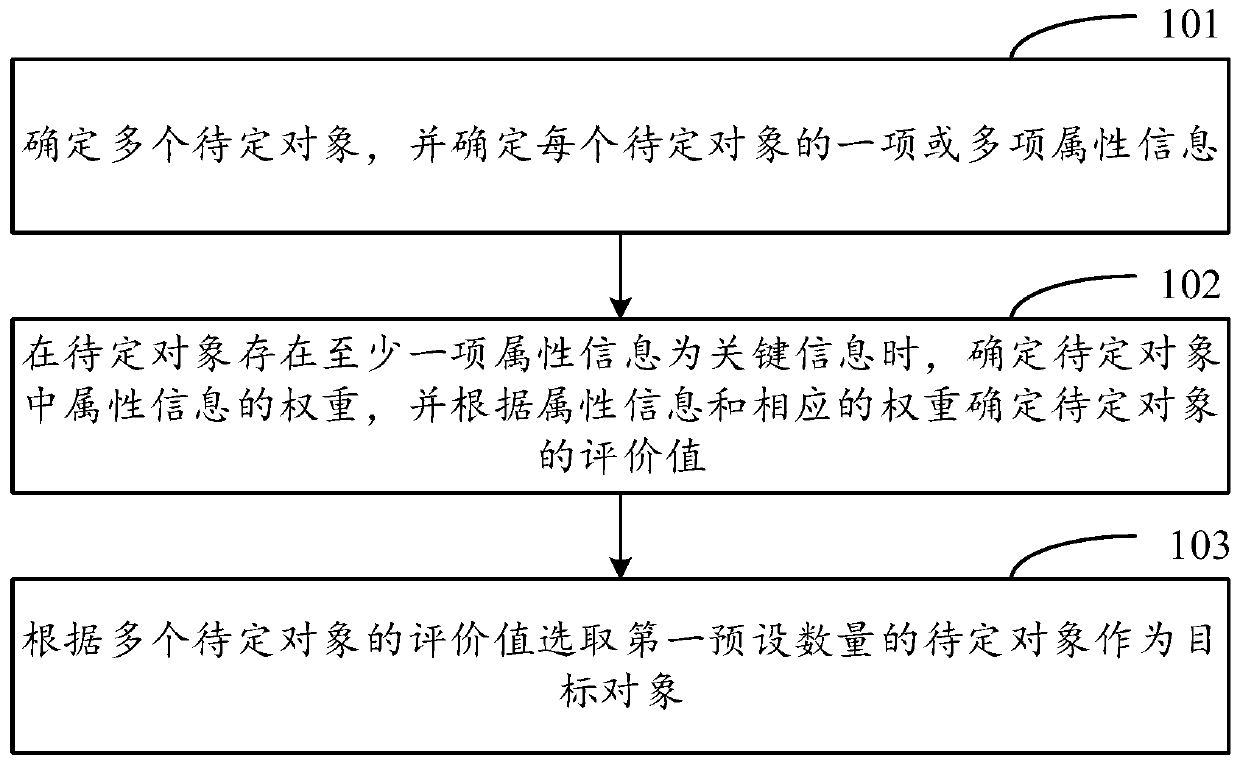

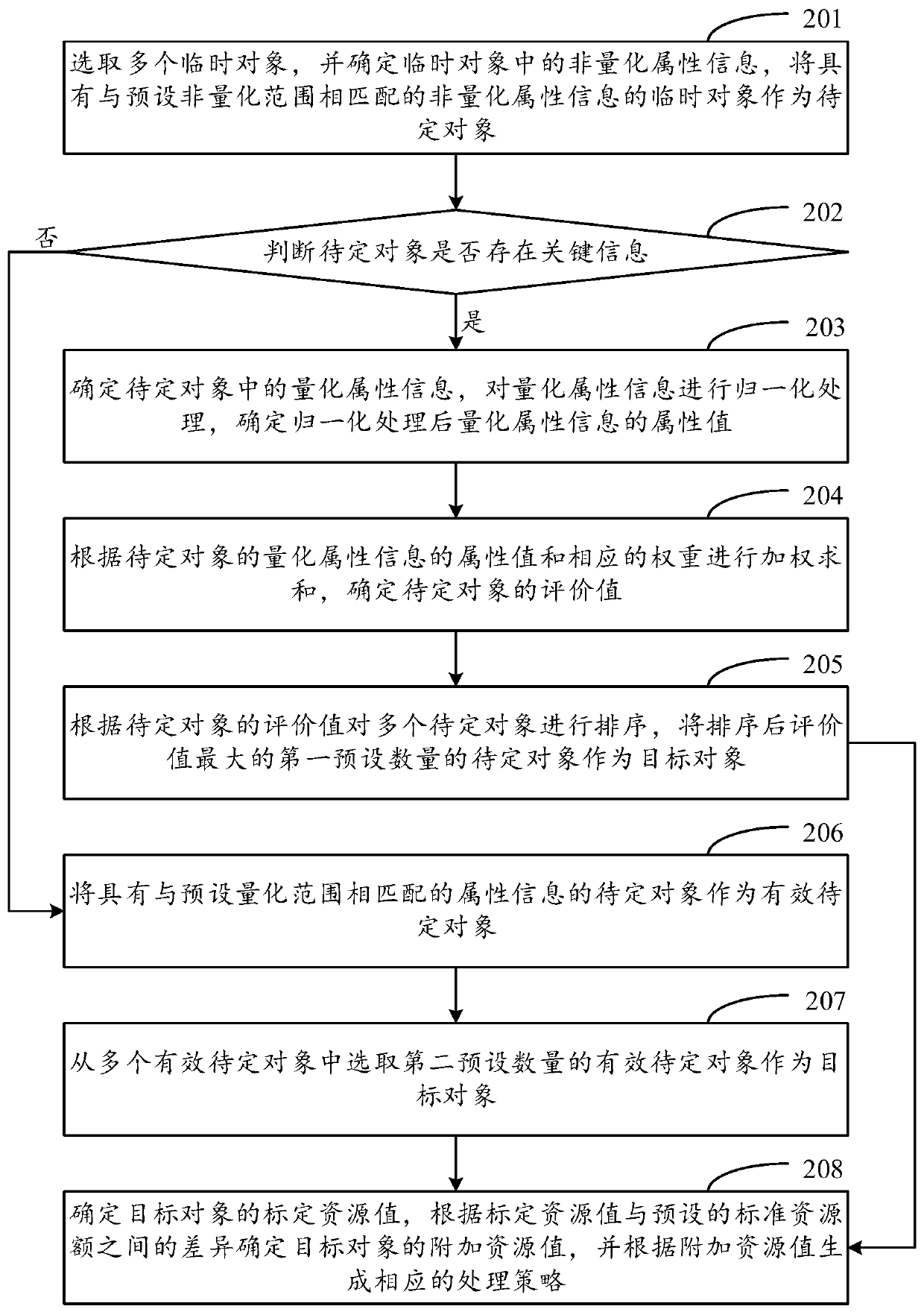

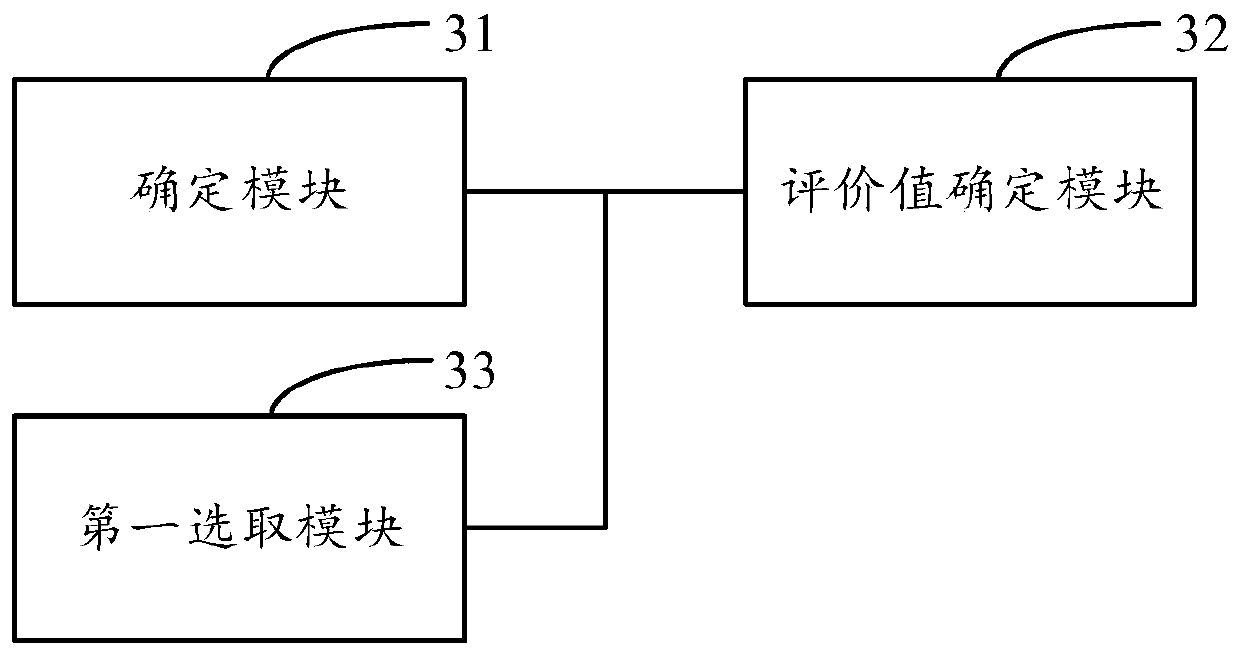

Object selection method and device, storage medium and electronic equipment

PendingCN110533485AEasy to handleReduce labor costsDiscounts/incentivesMarket data gatheringSoftware engineeringElectric equipment

The invention provides an object selection method and a device, a storage medium and electronic equipment, wherein the method comprises the steps: determining a plurality of to-be-determined objects,and determining one or more pieces of attribute information of each to-be-determined object; when at least one item of attribute information of the to-be-determined object is key information, determining the weight of the attribute information in the to-be-determined object, and determining an evaluation value of the to-be-determined object according to the attribute information and the corresponding weight; and selecting a first preset number of to-be-determined objects as target objects according to the evaluation values of the to-be-determined objects. According to the object selection method and the device, the storage medium and the electronic equipment provided by the embodiment of the invention, manual participation is not needed, the labor cost can be reduced, and the efficiency can be improved; the target object is objectively selected based on the evaluation value of the to-be-determined object, the selection result is more accurate, and the selected target object better meets the requirements of subsequent processing.

Owner:JINGUAZI TECH DEV CO LTD

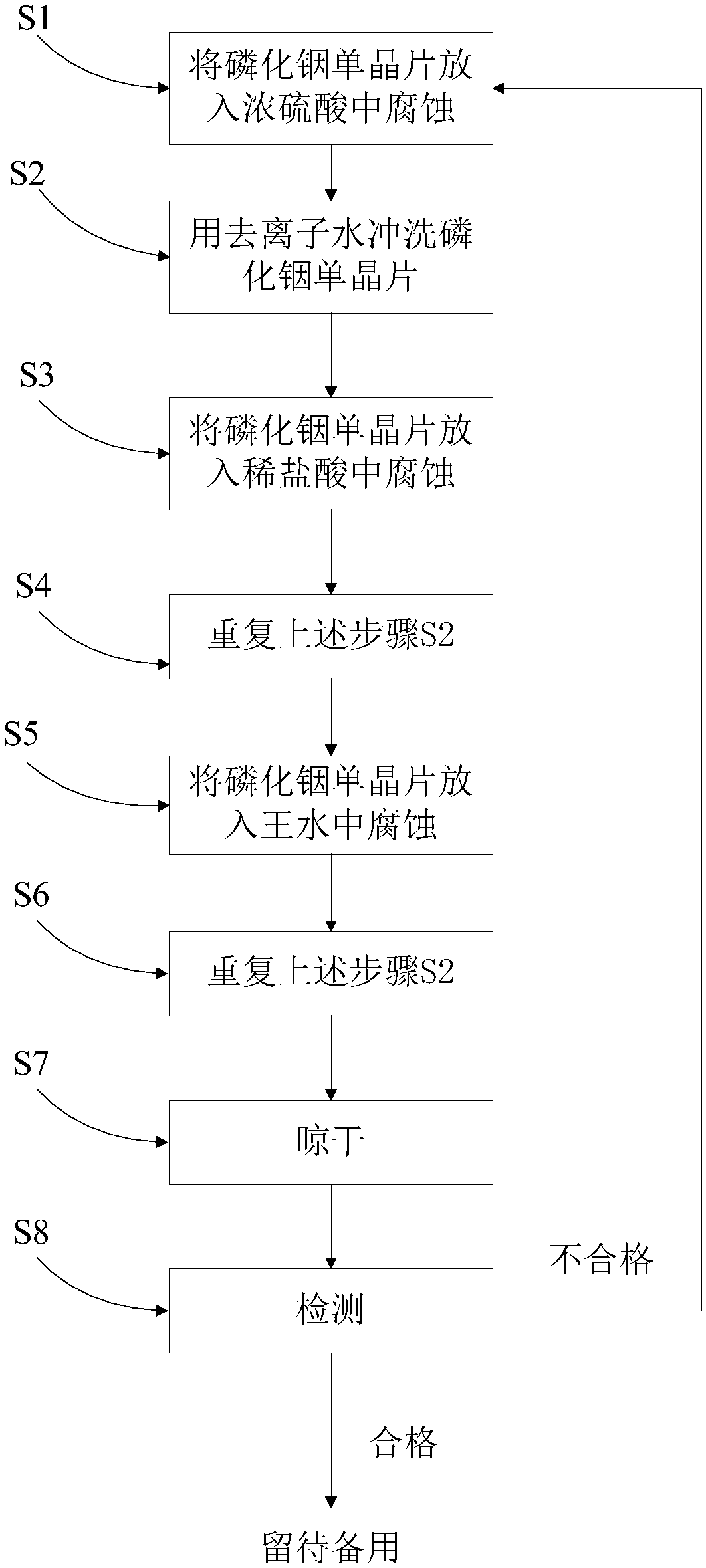

Method for corroding indium phosphide single crystal wafer

InactiveCN107723802AEfficient removalMeet the requirements of subsequent processingPolycrystalline material growthAfter-treatment detailsAcid corrosionSingle crystal

The invention discloses a method for corroding an indium phosphide single crystal wafer. The method comprises the following steps: S1, corroding an indium phosphide single crystal wafer into concentrated sulfuric acid; S2, irrigating the indium phosphide single crystal wafer with deionized water; S3, corroding the indium phosphide single crystal wafer in diluted hydrochloric acid; S4, repeating the step S2; S5, corroding the indium phosphide single crystal wafer in chloroazotic acid; S6, repeating the step S2; and S7, drying in the air. According to the method, the split and ground indium phosphide single crystal wafer is corroded by adopting an acid corrosion mode, the damage layer and stress layer on the surface of the single crystal wafer can be effectively removed, and a clean single crystal wafer surface can be obtained to meet the requirement for subsequent processing.

Owner:珠海鼎泰芯源晶体有限公司

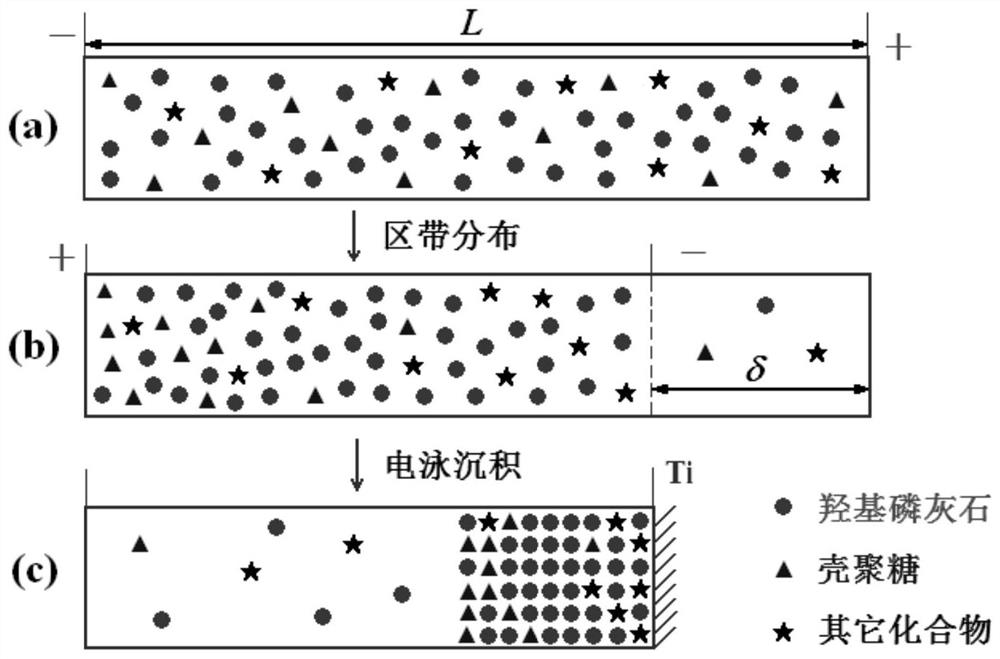

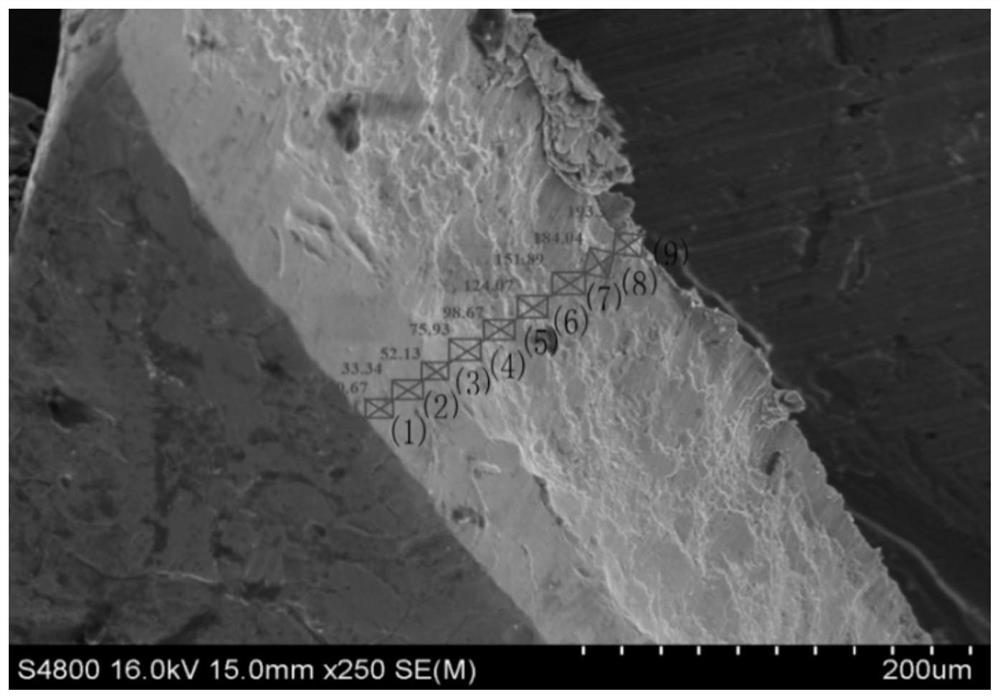

Zone electrophoresis and electrophoretic deposition method for preparing HA gradient composite coating material

InactiveCN113106519AControl travel differenceProperties of Distinct Gradient DistributionsElectrophoretic coatingsDispersed mediaElectrophoresis

The invention discloses a zone electrophoresis and electrophoretic deposition method for preparing an HA gradient composite coating material. The method specifically comprises the following steps: (1) preparation of HA turbid liquid: adding 3-4 different fine particulate matters which are subjected to screening pretreatment and contain HA into a dispersion medium according to a certain mass ratio, adding a synergistic dispersant, and standing and aging after ultrasonic dispersion; (2) pretreatment of a titanium sheet substrate; (3) zone electrophoresis distribution of HA turbid liquid: using two pre-treated titanium sheets as a positive electrode and a negative electrode of zone electrophoresis to be placed in the HA turbid liquid in parallel, applying a direct-current constant voltage, and forming zone distribution by electrophoresis of the fine particles; (4) inserting a third pretreated titanium sheet as a negative electrode, and connecting a conversion electrode for electrophoretic deposition; and (5) depositing on the surface of the third pretreated titanium sheet to obtain the HA gradient composite coating material. The HA composite coating material realizes obvious gradient distribution in the normal direction by adopting a physical electrophoretic deposition method, the required equipment is simple and convenient, the operation is simple, and the adhesive force of the composite coating is moderate.

Owner:FUJIAN NORMAL UNIV

Composite additive for reinforcing nickel laterite ore briquette and preparation method and application thereof

The invention provides a composite additive for reinforcing a nickel laterite ore briquette and a preparation method and application thereof. The composite additive comprises 5-10 wt% of water glass, 50-65 wt% of anthracite, 5-10 wt% of sodium humate and 10-30 wt% of limestone. The preparation method is to weigh and uniformly mix anthracite, sodium humate and limestone according to the mass ratios to obtain a mixture; and then, water glass is singly mixed. The composite additive can prominently improve the yield and the cold / hot-state strength of the nickel laterite ore briquette, and can be applied to the nickel laterite ore briquette.

Owner:CENT SOUTH UNIV

A kind of preparation method of titanium-aluminum-stainless steel composite plate

ActiveCN105172308BEasy to operateEasy to implementLaminationLamination apparatusMaterials preparationSheet steel

The invention discloses a preparing method for a titanium-aluminum-stainless-steel composite plate and belongs to field of composite material preparation. The method comprises the steps that a titanium plate, an aluminum plate / foil and a stainless steel plate are assembled, a titanium-aluminum-stainless-steel interlayer structure is formed and put into vacuum hot press equipment to be treated for 0.5-2 hours at the pressure of 1-4 MPa at 550-650 DEG C, and then cooling treatment is conduced to obtain the titanium-aluminum-stainless-steel composite plate. The preparing method is simple in operation and convenient to implement, a titanium / aluminum interface and an aluminum / stainless steel interface form metallurgical bonding through even dispersing, and the titanium-aluminum-stainless-steel composite plate is obtained.

Owner:KUNMING UNIV OF SCI & TECH

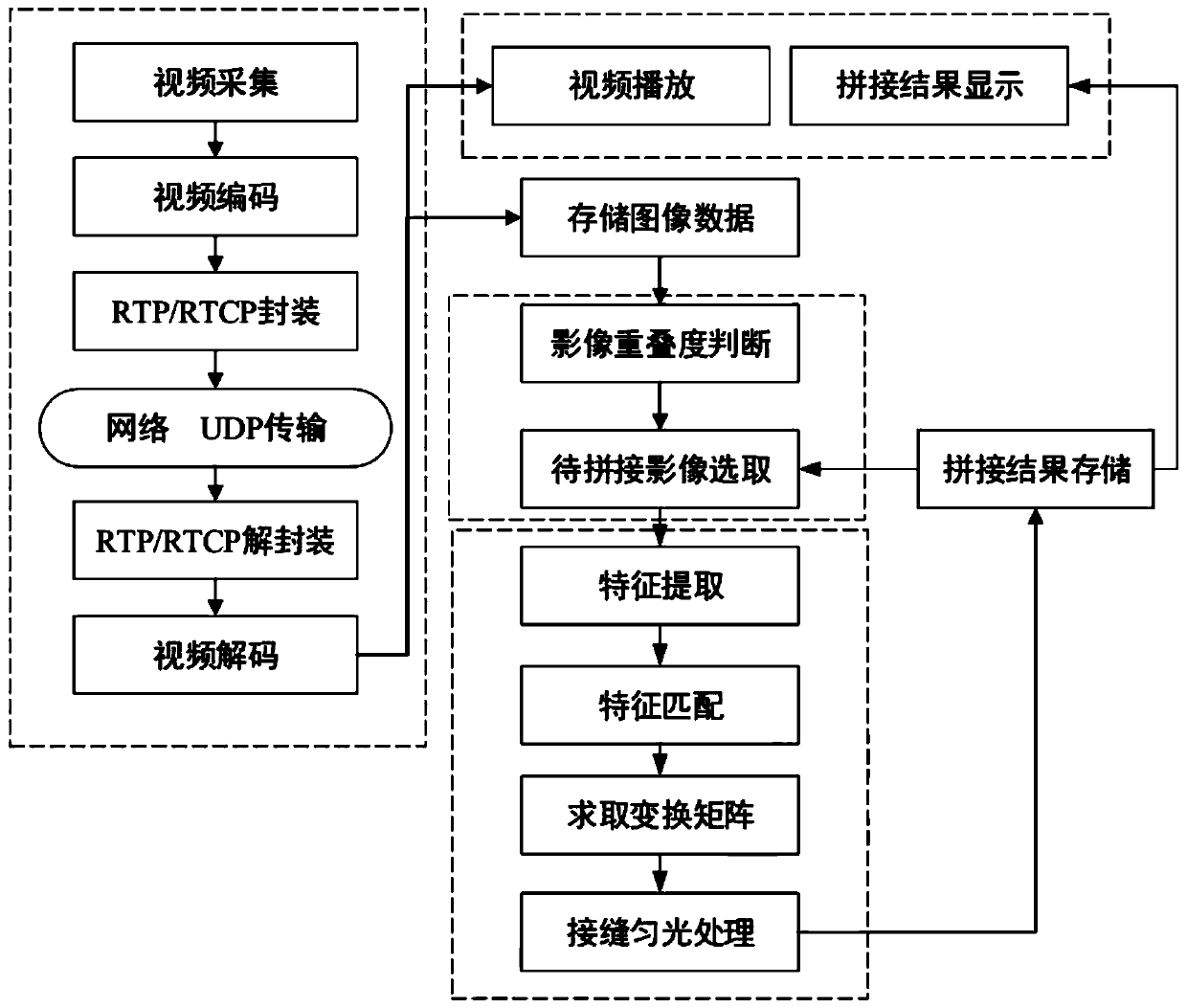

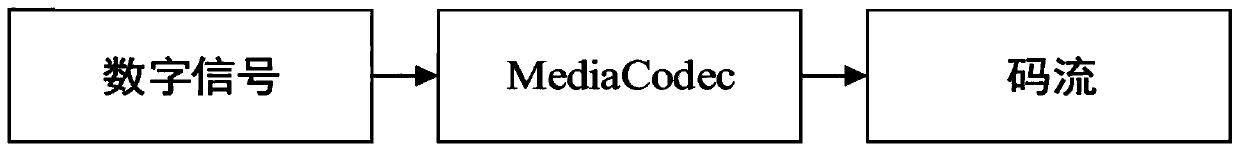

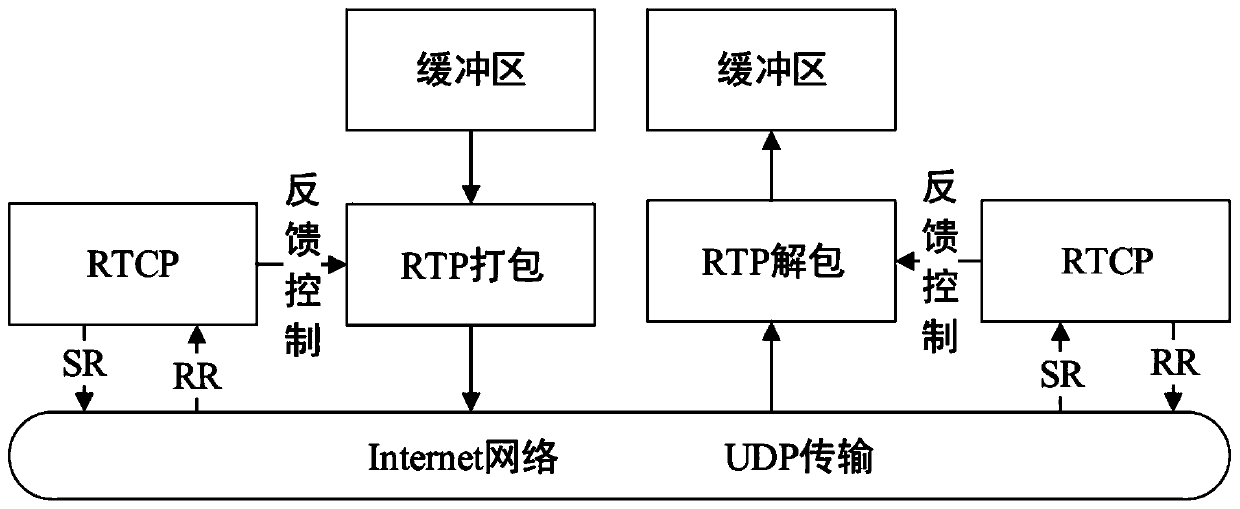

A high-efficiency processing system for UAV images

ActiveCN107371040BNo guarantee of qualityMeet the requirements of subsequent processingTelevision system detailsColor television detailsComputer graphics (images)Uncrewed vehicle

The invention provides an unmanned aerial vehicle (UAV) image efficient processing system. Key technologies, such as the image compression encoding technology and the network transmission technology, involved in UAV image acquisition and transmission, are improved. The UAV image stitching fusion method is improved. A UAV aerial image acquisition, transmission and efficient processing system is realized. The system achieves functions such as UAV aerial image acquisition, compression encoding and real-time transmission through programming based on Android on a mobile phone. At a server side, a transmitted video is decoded, played and stored. The degree of overlap between stored images can be judged, and the judgment result can guide image thinning. After thinning, part of the images are selected and stitched. The quality of stitching is ensured, and the speed of region stitching is increased. The system can meet the requirement of real-time acquisition and transmission, can realize UAV image stitching and processing without control points, and can achieve a good visual effect.

Owner:安徽图联科技有限公司

A calibrating device and calibrating method for a superalloy open case

The invention discloses a shape correcting device of a high temperature alloy split-opened casing. The shape correcting device comprises a first outer shape correcting ring and a second outer shape correcting ring; an annular stopping opening is formed in the inner side of each outer shape correcting ring, and the diameter of each annular stopping opening is the same as the theoretical outer diameter of the end surface of the casing subject to shape correcting; a plurality of wedge holes are formed in the end surface of each outer shape correcting ring in the circumferential direction evenly and penetrate through the annular stopping openings in the outer shape correcting rings, and the shape correcting device further includes wedge blocks matched with the wedge holes; and a supporting rodinner shape supporting is connected with a supporting block and a mandrel, the outer shape surface of the supporting block is consistent with the inner shape surface of the casing subject to shape correcting, and the supporting rod is arranged in the radial direction of the casing subject to shape correcting. The invention further discloses a shape correcting method of the split-opened casing. Through the combination of cold shape correcting and heat shape correcting of the split-opened casing, the problem that the design requirements are not met due to the fact that the ellipticity of the split-opened casing changes too much is solved, the fact that the ellipticity of the split-opened can meet the requirements of the subsequent processing is ensured, the difficulty of the subsequent processing process is simplified, the processing quality of the parts is improved, and the rejection rate is reduced.

Owner:AECC AVIATION POWER CO LTD

Heat treatment method of drilling tool steel

PendingCN113981190AImprove toughnessFull recovery, recrystallization and refinementTool steelHardness

The invention belongs to the technical field of production and manufacturing of drilling tool steel, and particularly relates to a heat treatment method of drilling tool steel. According to the method, austenite grains can be fully recovered, recrystallized and refined through reasonable control over deformation temperature and the deformation amount in a forging process, and full preparation is made for improving toughness of steel; and then a cooling rate after forging is controlled, and slow cooling is conducted, so that in a deformation austenite transformation process, proeutectoid ferrite can be fully nucleated and grow up, and necessary conditions are provided for reducing a hardness value of a forging stock. According to the invention, furnace cooling is added after precision forging; and after the furnace cooling, the structure is mainly lath bainite, lath spacing is large, part of grain structure appears, full preparation is made for annealing, and a final blank is obtained after annealing and provided for a user.

Owner:CHENGDU ADVANCED METAL MATERIALS IND TECH RES INST CO LTD

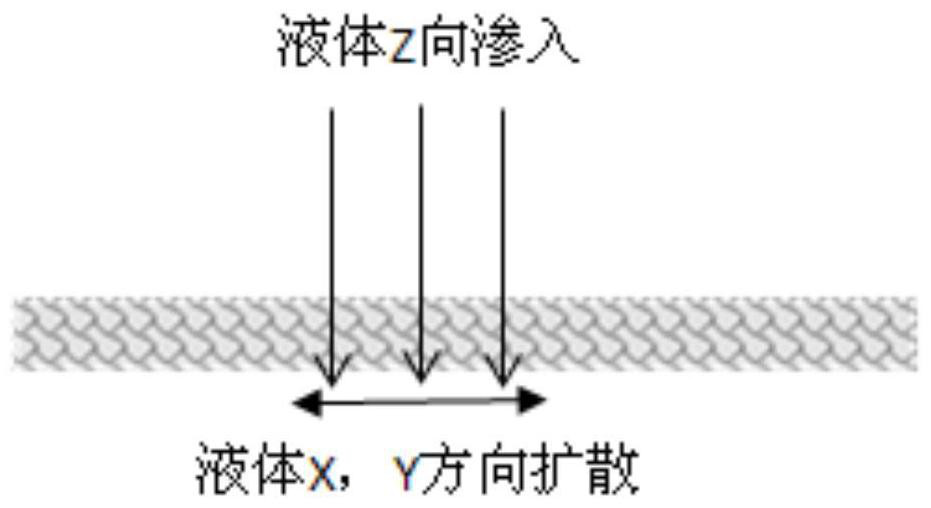

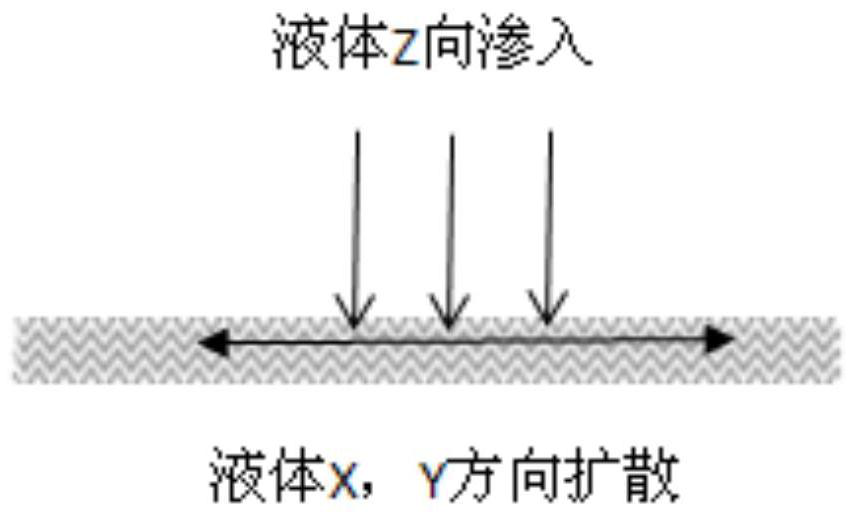

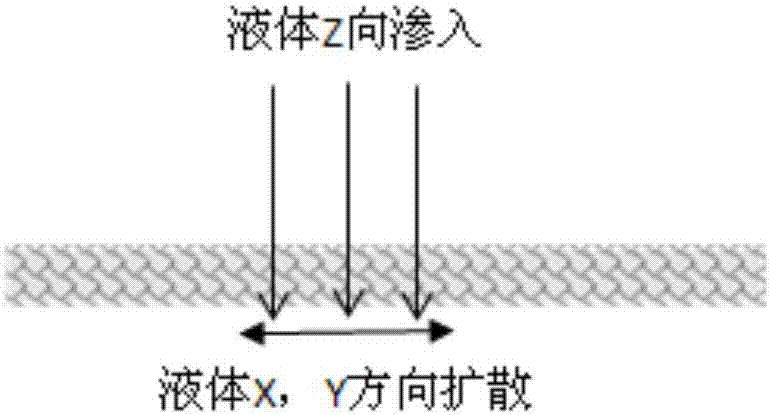

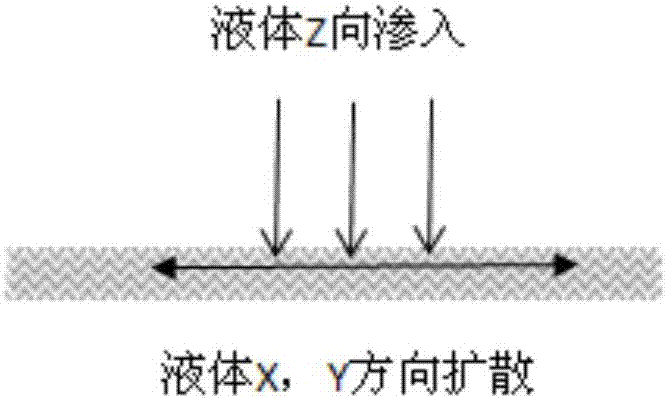

Thermal composite rapid infiltration diversion material and application thereof

PendingCN114161783ANot easy to layerMeet the requirements of subsequent processingLamination ancillary operationsPersonal careCellulose fiberCeramic materials

The invention provides an on-line thermal composite rapid infiltration flow guide material and application thereof. The on-line thermal composite rapid infiltration flow guide material comprises a rapid infiltration flow guide layer and a dust-free paper layer which are in liquid communication with each other, the rapid infiltration flow guide layer is made of a porous non-woven material and accounts for 8-85% of the total mass of the composite rapid infiltration flow guide material; the dust-free paper layer comprises at least one fiber layer, the fiber layer is made of cellulosic fibers and bi-component composite fibers, and the mass of the dust-free paper layer accounts for 15-92% of the total mass of the composite flow guide material dust-free paper; the mass of the cellulose fibers in the fiber layer accounts for 5-95% of the total mass of the fiber layer, and the mass of the two-component composite fibers accounts for 5-95% of the total mass of the fiber layer; when the number of the fiber layers is two or more, the adjacent fiber layers are communicated through liquid. A sanitary napkin product prepared from the composite quick-seepage flow guide material is fluffy, soft, good in rebound resilience, low in production cost, good in overall performance and simple and novel in structure, not only has the functions of quick liquid flow guide, quick seepage, diffusion and temporary liquid storage, but also has excellent reverse seepage resistance.

Owner:FITESA CHINA AIRLAID

A kind of heavy oil hydrogenation catalyst and preparation method thereof

ActiveCN103769118BShorten drying timeAvoid pollutionCatalyst carriersMetal/metal-oxides/metal-hydroxide catalystsDry basisBULK ACTIVE INGREDIENT

The invention discloses a heavy oil hydrogenation catalyst and a preparation method thereof. The heavy oil hydrogenation catalyst comprises a carrier and an active ingredient; the carrier is aluminum oxide, and is prepared from pseudo-boehmite with dry basis content below 50% via moulding; the active ingredient are metals selected form family VIII, Co or Ni, and / or family VI B, Mo or W. The preparation method comprises following steps: preparation of pseudo-boehmite, preparation of the carrier, and loading of the active ingredient. The heavy oil hydrogenation catalyst is capable of maintaining high demetalization, desulphurization, and carbon residue removing activities, simplifying drying process of pseudo-boehmite preparation, avoiding dust pollution caused by moulding process, increasing production efficiency, reducing production energy consumption, and reducing catalyst cost further.

Owner:CHINA PETROLEUM & CHEM CORP +1

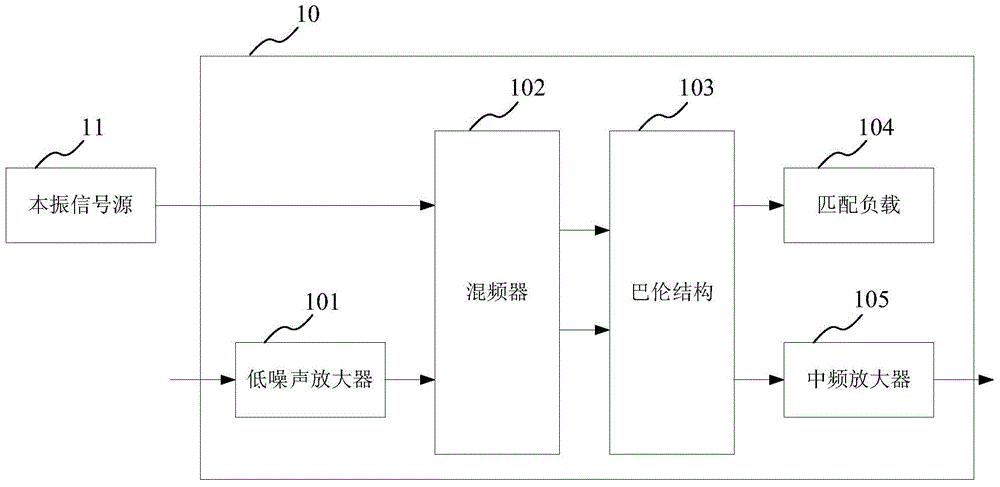

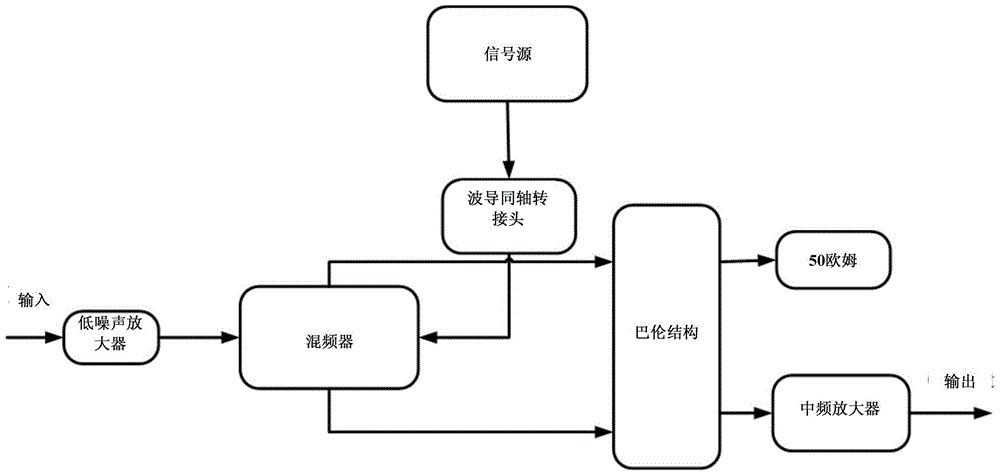

A frequency spreading structure

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

Online thermal composite quick infiltration guide material

InactiveCN107215034ADifferent structureDifferent performanceLamination ancillary operationsPersonal careCellulose fiberMaterials science

The invention provides an online thermal composite quick infiltration guide material. The online thermal composite quick infiltration guide material comprises a quick infiltration guide layer and a dust-free paper layer which are communicated with each other by virtue of liquid; the quick infiltration guide layer is prepared from a porous nonwoven material and accounts for 8 to 85 percent of the total weight of the composite quick infiltration guide material; the dust-free paper layer comprises at least one fiber layer, the fiber layer is prepared from cellulose fibers and dual-component composite fibers, and the dust-free paper layer accounts for 15 to 92 percent of composite guide material dust-free paper; the cellulose fibers in the fiber layer account for 5 to 95 percent of the total weight of the fiber layer, and the dual-component composite fibers account for 5 to 95 percent of the total weight of the fiber layer; and when the layer number of the fiber layers is two or more, the two adjacent fiber layers are communicated with each other by virtue of liquid. A sanitary towel product prepared from the composite quick infiltration guide material is loose, soft, good in resilience, low in production cost, good in overall performance, simple and novel in structure, not only capable of quickly guiding, infiltrating, dispersing and temporarily storing the liquid, but also excellent in back-permeability resistance.

Owner:FITESA CHINA AIRLAID

Tobacco leaf loose moisture regain equipment and its water adding control method

ActiveCN103844337BImprove stabilityMeet the requirements of subsequent processingTobacco preparationGear pumpProgrammable logic controller

The invention discloses a tobacco leaf loosening and dampening device and a water adding control method thereof. The tobacco leaf loosening and dampening device comprises a dampening rotary drum, a water tank, an inlet vibration groove, an outlet vibration groove, an electronic belt scale, a moisture detector, a dampening rotary drum inlet water adding system, a dampening rotary drum outlet water adding system and a programmable logic controller. The dampening rotary drum inlet water adding system comprises a first double-medium atomizing nozzle and a first gear pump, and the dampening rotary drum outlet water adding system comprises a second double-medium atomizing nozzle and a second gear pump. The water adding control method comprises an inlet water adding amount control method and an outlet water adding amount control method. By the tobacco leaf loosening and dampening device and the water adding control method, tobacco leaf moisture fluctuation is effectively reduced, the tobacco leaf material moisture stability is improved through tobacco leaf material moisture preliminary adjustment and quick feedback adjustment, and the stability of the inherent quality of follow-up cigarette products is improved.

Owner:CHINA TOBACCO SHANDONG IND

Device and method for improving sensory quality of tobacco lamina fermented by biological enzyme

PendingCN112971196AReduce moisture contentMeet the requirements of subsequent processingTobacco preparationTobacco treatmentBiotechnologyWarm water

The invention relates to the field of cigarette tobacco leaf raw material processing, in particular to a device and a method for improving sensory quality of tobacco lamina after biological enzyme fermentation, and is characterized in that the device comprises a porous mesh belt and a water washing and hot air drying box body, and the porous mesh belt penetrates through the water washing and hot air drying box body, and is used for conveying the fermented tobacco sheet materials for washing and drying treatment. The method comprises the following steps: washing fermented laminas with warm water, and drying the laminas with hot air to remove small molecular chemical substances generated on the surfaces of the tobacco leaves through biological enzymolysis. Compared with the prior art, the method has the outstanding advantages that small-molecule chemical substances generated by degrading the tobacco lamina by the biological enzyme can be quickly removed through water washing and drying, the chemical component coordination of the tobacco lamina is improved, the sensory quality of the tobacco lamina is further improved, and the use value of the tobacco lamina is improved.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

Electronic Forming Method of Spinning Frame Cops

InactiveCN104153060BFulfil requirementsMeet the requirements of high-speed retreatContinuous wound-up machinesMathematical modelElectric machinery

Provided is a spinning frame tube electronic forming method. A conical cross winding mode is adopted for a tube, in the winding process, a steel collar plate is independently transmitted by an independent motor, and the steel collar plate repeatedly conducts a plurality of short stroke lifting movements upwards from the bottom winding position of the tube; through the establishment of a preference mathematic model, the speed controllable and position controllable transmission mode of the steel collar plate is completed, and thus the equal thread pitch winding and leveling up arrangement of the tube on a forming conical surface are achieved, and the internal forming structure of the tube is controlled according to the continuously developing technical state of a spring frame through the reasonable selecting optimization of parameters in the mathematic model. In any short stroke lifting process, the proportion of ascending time and descending time can be adjusted as needed. The spinning frame tube electronic forming method can achieve the technical purpose of meeting the forming requirements of different spinning varieties. A tube bottom forming section is further arranged, the tube with the large volume and good appearance forming is formed, the requirement for automatic winding high speed unwinding of a subsequent procedure can be met, and the production efficiency is improved.

Owner:PACIFIC MECHATRONIC GRP

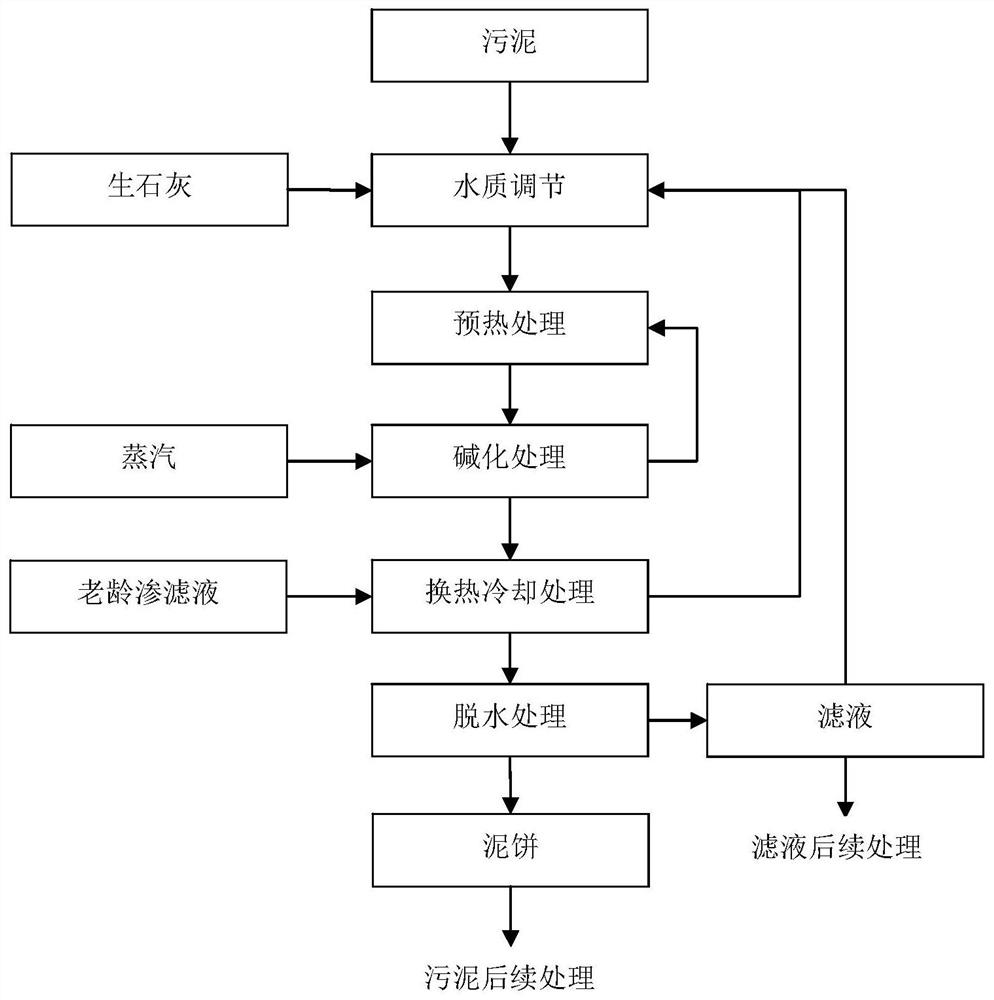

A method and system for synergistic sludge dewatering treatment of aged leachate in a landfill

ActiveCN112661366BImprove the breaking effectImprove dehydration effectSludge treatment by de-watering/drying/thickeningWaste based fuelProcess engineeringCo-processing

The invention discloses a method and a system for synergistic sludge dewatering treatment of aged leachate in a landfill. The method comprises the following steps: mixing sludge and aged leachate, adding alkali for alkalization treatment and dehydration treatment, and completing Co-processing of aged leachate and sludge. The system includes an alkalizing unit and a dehydrating unit. The method for synergistic sludge dewatering treatment of aged leachate of a landfill in the present invention takes the aged leachate of the landfill as the dilution water for sludge dewatering treatment, and adds alkali for alkalization treatment and dehydration treatment, so as to improve the sludge dewatering process. At the same time of wall effect and dehydration performance, it can also realize the resource utilization of aged leachate, which has the advantages of simple process, short process, convenient operation, high treatment efficiency, low dosage of chemicals, low energy consumption, low cost, good dehydration effect, and two At the same time, the pH of the obtained filtrate is easy to adjust, the conductivity is suitable, and the subsequent advanced treatment is easy, so it has a good use value and a good application prospect.

Owner:HUNAN JUNXIN ENVIRONMENTAL PROTECTION CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com