Composite dustless paper and production process and application thereof

A technology of dust-free paper and composite fiber, which is applied in medical science, bandages, absorbent pads, etc., can solve the problems of complex process, high production cost, and reduce sanitary napkins, etc., to increase the microporous structure, improve efficiency, and reduce The effect of the supply chain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

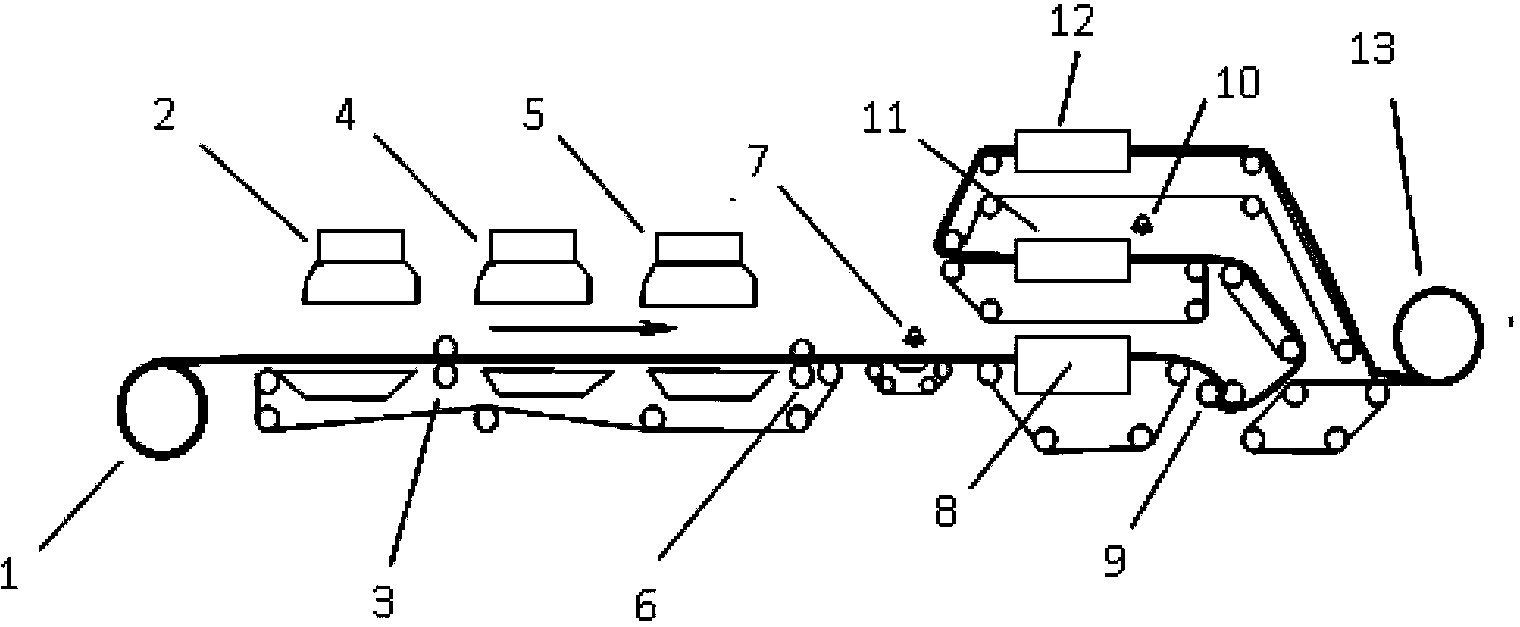

Method used

Image

Examples

Embodiment 1

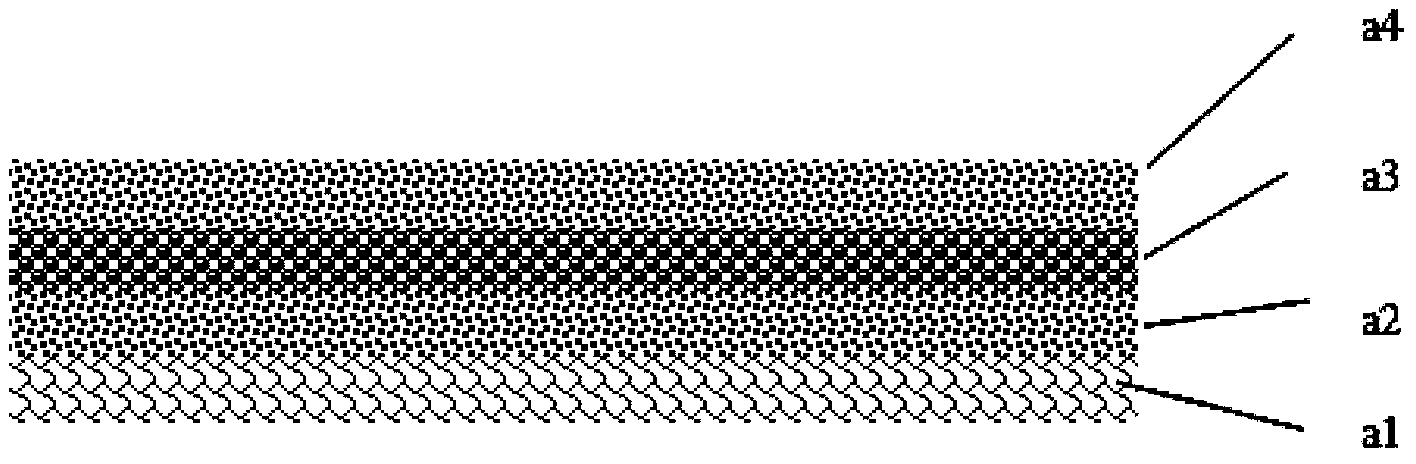

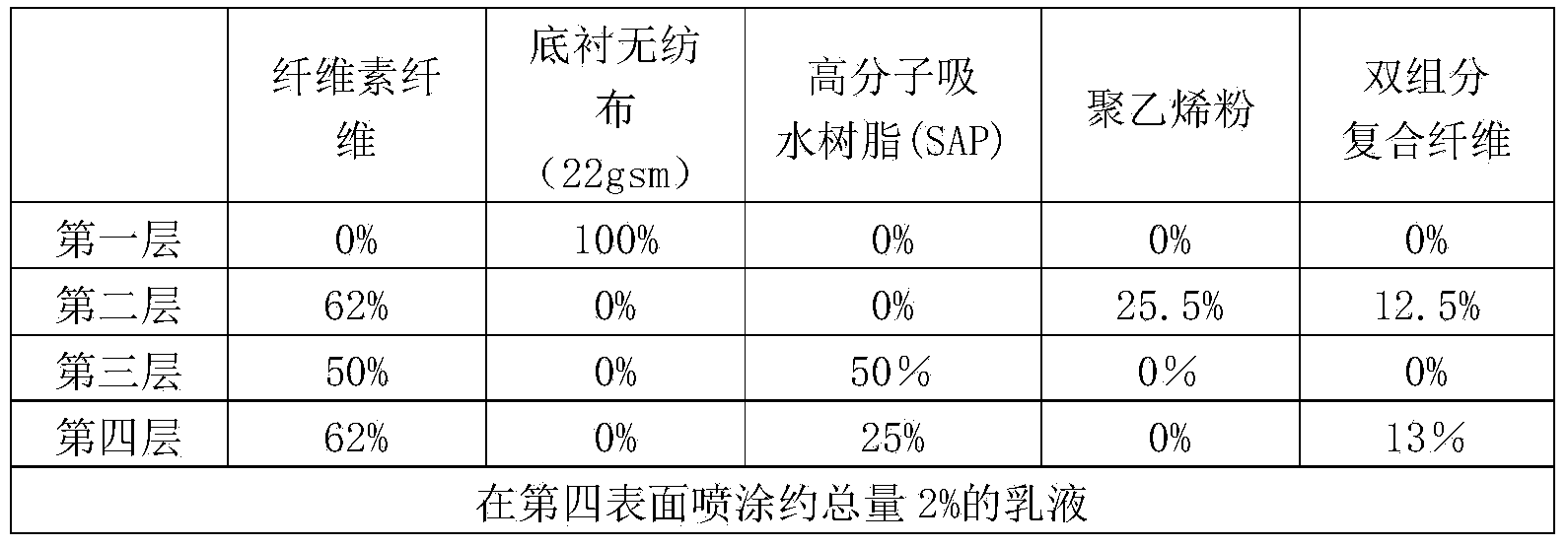

[0076] The total weight of the dust-free paper is about 175g / m2, and the thickness is about 1.45mm. The specific raw materials and structure are as follows: the cellulose fiber is Weyerhauser NB416, and the fiber length is about 2-5mm. The bicomponent composite fiber is composed of a core layer and a skin layer, the core layer is polypropylene (PP), the skin layer is polyethylene (PE), the fiber length is about 3-6mm, and the fineness is about 1.7-3.0 decitex. The non-woven fabric adopts 22gsm polypropylene spun-bonded non-woven fabric, and the polymer water-absorbing resin comes from Sandia-930, or from manufacturers such as Stockhausen, Sumitomo, Shokubai, etc. In this embodiment, the emulsion is sprayed on the fourth layer, Vinnapas192 from Wacker Company product.

[0077] The composite dust-free paper structure includes four layers, the basis weight of the first layer accounts for about 12.6% of the total weight of the product, the weight of the second layer accounts for a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com