Method for producing high-performance regenerated polyester colored special-shaped filaments on basis of waste polyester textile products

A technology of waste textiles and recycled polyester, applied in the field of textile and chemical fibers, can solve the problems of high energy consumption and secondary pollution, achieve efficient impurity removal, save dyeing steps, and achieve good product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

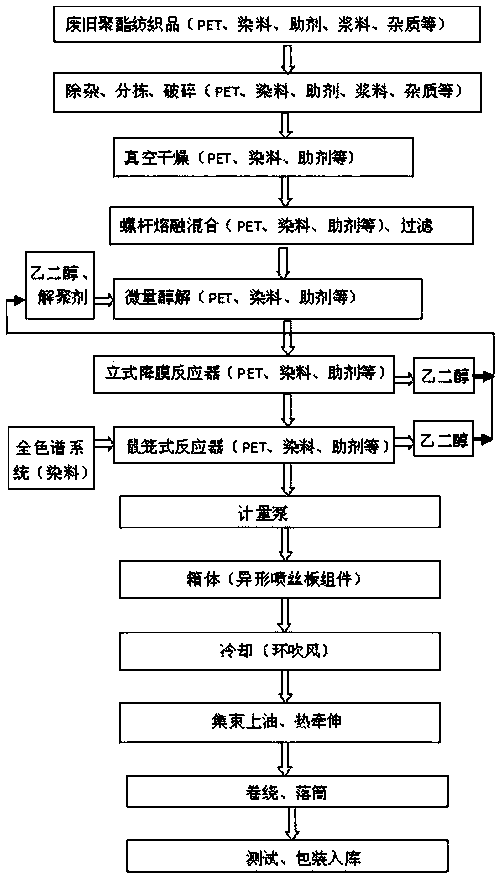

[0025] Such as figure 1As shown, the method for producing high-performance regenerated polyester colored special-shaped filaments based on waste polyester textiles in this embodiment includes the following steps: after removing impurities, sorting, crushing, etc., waste textiles are put into a vacuum drum, and the drum The temperature is 190°C, and it is dried for 6 hours. Then put the dried waste textiles into the screw, the length-to-diameter ratio of the screw is 25, and the temperatures of the first to seventh zones of the screw are 250°C, 265°C, 270°C, 275°C, 275°C, 274°C, 272°C respectively , The screw head pressure is 18Mpa. The regenerated polyester melt enters the vertical falling film reactor after primary filtration, and the temperature is 270°C. Ethylene glycol was added online in the front section of the falling film reactor, and the addition amount was 0.04%. After reacting for 30 minutes, it enters the squirrel-cage reactor after being filtered by a filter. T...

Embodiment 2

[0027] Such as figure 1 As shown, the method for producing high-performance regenerated polyester colored special-shaped filaments based on waste polyester textiles in this embodiment includes the following steps: after removing impurities, sorting, crushing, etc., waste textiles are put into a vacuum drum, and the drum The temperature is 200°C, and it is dried for 5 hours. Then put the dried waste textiles into the screw, the length-to-diameter ratio of the screw is 30, and the temperatures of the first to seventh zones of the screw are 255°C, 270°C, 273°C, 278°C, 278°C, 277°C, 275°C respectively , The screw head pressure is 16Mpa. The regenerated polyester melt enters the vertical falling film reactor after primary filtration, and the temperature is 275°C. Ethylene glycol was added online in the front section of the falling film reactor, and the addition amount was 0.08%. After reacting for 45 minutes, it is filtered through a filter and enters the squirrel-cage reactor. ...

Embodiment 3

[0029] Such as figure 1 As shown, the method for producing high-performance regenerated polyester colored special-shaped filaments based on waste polyester textiles in this embodiment includes the following steps: after removing impurities, sorting, crushing, etc., waste textiles are put into a vacuum drum, and the drum The temperature is 190°C, and it is dried for 6 hours. Then put the dried waste textiles into the screw, the length-to-diameter ratio of the screw is 25, and the temperatures of the first to seventh zones of the screw are 250°C, 265°C, 270°C, 275°C, 275°C, 274°C, 272°C respectively , The screw head pressure is 18Mpa. The regenerated polyester melt enters the vertical falling film reactor after primary filtration, and the temperature is 270°C. Ethylene glycol was added online in the front section of the falling film reactor, and the addition amount was 0.04%. After reacting for 30 minutes, it enters the squirrel-cage reactor after being filtered by a filter. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| Irregularity | aaaaa | aaaaa |

| Irregularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com