Spinning frame tube electronic forming method

A spinning frame and tube bottom forming technology, which is applied to spinning machines, continuous winding spinning machines, textiles and papermaking, etc. It can solve the problems of unsatisfactory high-speed unwinding, poor tube bottom forming, and inability to control bobbin forming. Adapt to different spinning varieties, etc., to achieve the effect of large capacity and good appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

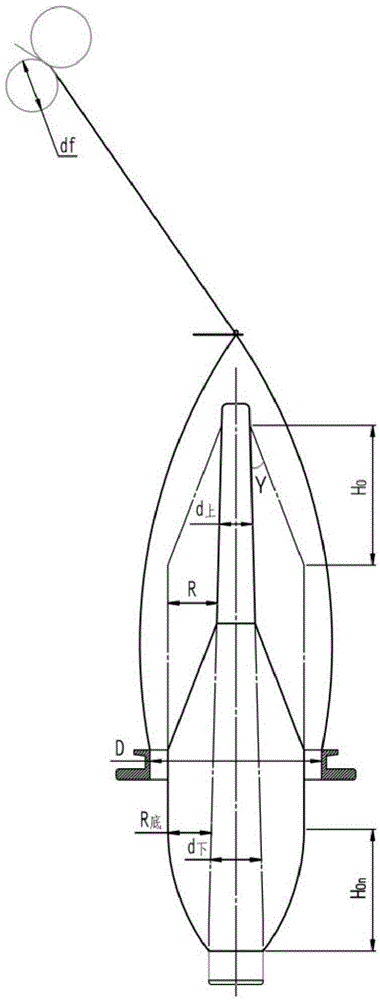

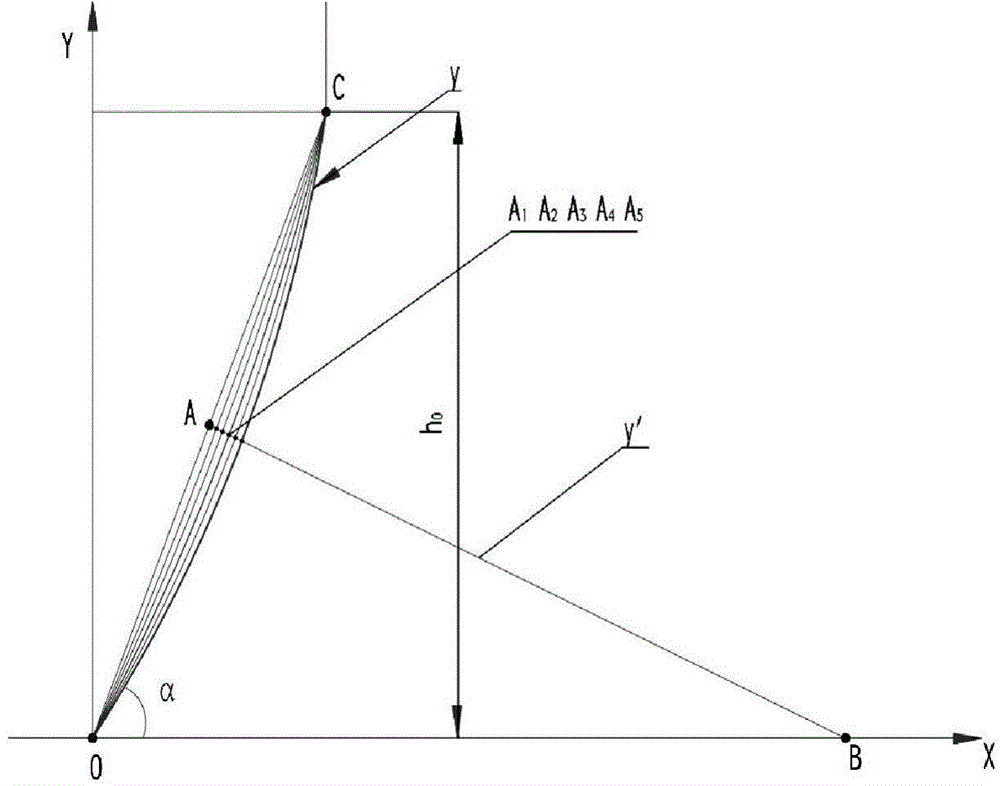

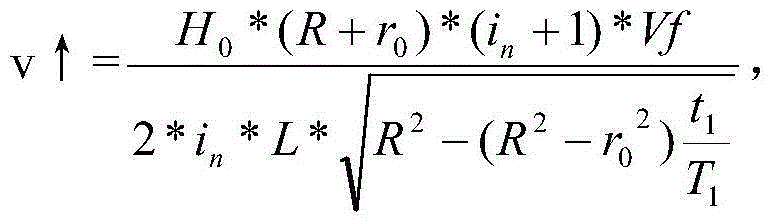

[0026] The electronic forming method for doffing bobbin of the spinning frame of the present invention includes a process of adjusting the position of the ring plate on the axial direction of the bobbin while the bobbin is winding, wherein the bobbin is in the form of conical cross-winding, steel The collar plate is driven by an independent motor alone, and repeats multiple short-stroke lifting actions upwards from the bottom winding position of the bobbin. Through the establishment of an optimal mathematical model, the collar plate completes the transmission mode with controllable speed and position. In this way, the equal-pitch winding and step-up setting of the bobbin on the forming cone surface can be realized, and the bobbin forming structure can be controlled through the reasonable selection and optimization of the parameters in the mathematical model. During any short stroke lifting process, the time ratio of rising and falling can be adjusted according to needs. The in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com