Zone electrophoresis and electrophoretic deposition method for preparing HA gradient composite coating material

A composite coating and zone electrophoresis technology, which is applied in the application field of composite coating material science, can solve the problem that HA composite coating materials do not have gradient distribution characteristics, and achieves improved negative charge properties, improved ionization degree, and simple operation process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

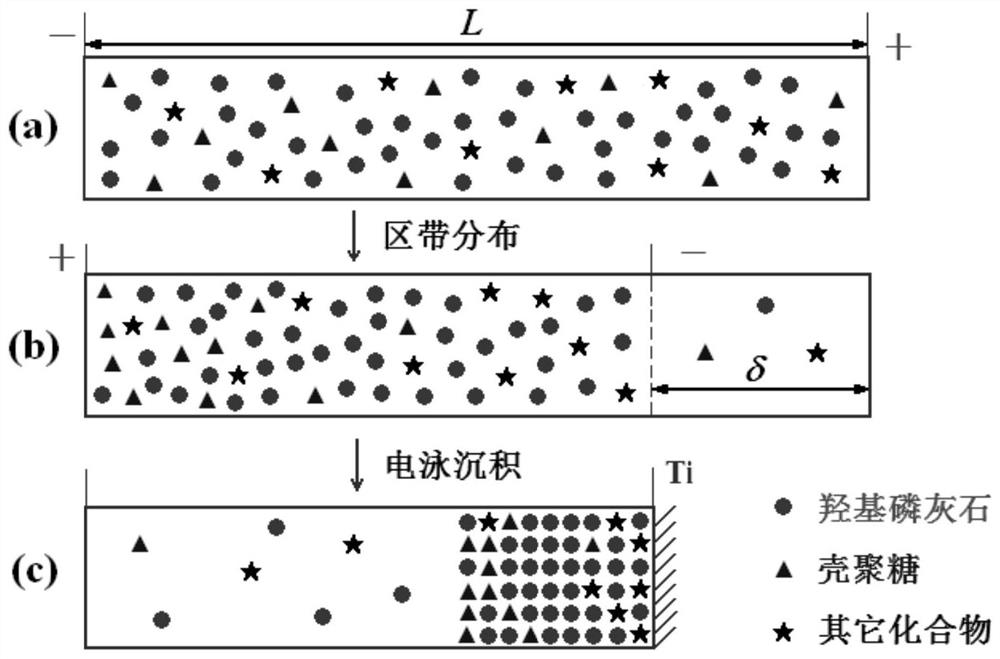

[0031] See attached figure 1 , a kind of zonal electrophoresis and electrophoretic deposition method for preparing HA gradient composite coating material, specifically comprises the following steps:

[0032] (1) Preparation of HA suspension: the mixture of HA and chitosan, metal oxide fine particles, metal oxide fine particles such as MgO, ZnO, SrCO 3 , SiO 2 , Fe 2 o 3Add it to the n-butanol dispersion medium, and add triethanolamine as a synergistic dispersant at the same time, ultrasonically disperse for 1 hour and then leave it to age for 24 hours to obtain a HA suspension; wherein, the amount of triethanolamine added is 1% of the volume of n-butanol ; In the present embodiment, the mixture includes 100 parts by weight of HA, 5 parts of chitosan, 1 part of ZnO particles and 1 part of SiO 2 particles;

[0033] (2) Pretreatment of the titanium sheet substrate: after polishing the pure titanium sheet with 800 mesh emery, use a mixed solution of hydrofluoric acid with a m...

Embodiment 2

[0040] See attached figure 1 , a kind of zonal electrophoresis and electrophoretic deposition method for preparing HA gradient composite coating material, specifically comprises the following steps:

[0041] (1) Preparation of HA suspension: the mixture of HA and chitosan, metal oxide fine particles, metal oxide fine particles such as MgO, ZnO, SrCO 3 , SiO 2 , Fe 2 o 3 etc. were added to the n-butanol dispersion medium, and triethanolamine was added as a synergistic dispersant at the same time, and the HA suspension was obtained after ultrasonic dispersion for 0.5h and standing for 30h; wherein, the addition amount of triethanolamine was 1% of the volume of n-butanol %; In the present embodiment, the mixture includes 110 parts by weight of HA, 4 parts of chitosan, 2 parts of ZnO particles and 1 part of SrCO 3 particles;

[0042] (2) Pretreatment of the titanium sheet substrate: polish the pure titanium sheet with 800 mesh emery, etch for 4 minutes with a mixed solution o...

Embodiment 3

[0048] A zonal electrophoresis and electrophoretic deposition method for preparing HA gradient composite coating materials, specifically comprising the following steps:

[0049] (1) Preparation of HA suspension: the mixture of HA and chitosan, metal oxide fine particles, metal oxide fine particles such as MgO, ZnO, SrCO 3 , SiO 2 , Fe 2 o 3 Add it to the n-butanol dispersion medium, and add triethanolamine as a synergistic dispersant at the same time, ultrasonically disperse for 0.5-1h, and then stand and age for 24-30h to obtain a HA suspension; wherein, the amount of triethanolamine added is n-butanol 1% by volume; in the present embodiment, the mixture includes 90 parts by weight of HA, 6 parts of chitosan, 2 parts of ZnO particles and 2 parts of MgO particles;

[0050] (2) Pretreatment of the titanium sheet substrate: after polishing the pure titanium sheet with 800 mesh emery, use a mixed solution of hydrofluoric acid with a mass fraction of 4% and a mixed solution of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com