A kind of preparation method of titanium-aluminum-stainless steel composite plate

A stainless steel plate and stainless steel technology, applied in the field of preparation of titanium-aluminum-stainless steel clad plate, can solve the problems of performance degradation and coarse structure, prevent diffusion, improve shear strength and tensile strength, and prevent iron-titanium intermetallic The effect of compound formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

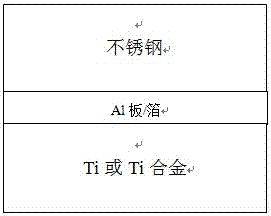

[0023] The preparation method of the titanium-aluminum-stainless steel composite plate in this embodiment specifically includes the following steps:

[0024] (1) Take 1mm thick TA1 titanium plate, 0.4mm thick pure aluminum foil and 8mm thick 304 stainless steel as raw materials, respectively cut into a size of 50mm×50mm; sand the surface of the cut titanium and stainless steel plates to remove surface oxidation Skin, etc., the aluminum plate is activated by acid washing on the surface, and after cleaning, it is combined in the order of titanium-aluminum-stainless steel;

[0025] (2) Place the combined composite material in a vacuum hot pressing device, pre-pressurize it to 4Mpa, after vacuuming, heat to 550°C at a heating rate of 15°C / min, then pressurize to a pressure of 4Mpa, and keep warm 2 hours; then, the furnace is cooled to 450°C, the temperature control accuracy is controlled at ±8°C, and the temperature is kept for 1 hour. Then, cut off the power supply and cool to room te...

Embodiment 2

[0028] (1) Take 2mm thick TA1 titanium plate, 0.05mm thick pure aluminum foil and 2mm thick 316 stainless steel as raw materials, respectively cut into a size of 50mm×50mm; the surface of titanium and stainless steel plates are treated with sandblasting to remove surface oxide scale, etc. The aluminum plate is activated and cleaned by surface pickling; then, it is combined in the order of titanium-aluminum-stainless steel;

[0029] (2) Place the combined composite material in a vacuum hot pressing device, pre-pressurize it to 0.5Mpa, after vacuuming, heat to 650°C at a heating rate of 5°C / min, and then pressurize to a pressure of 1Mpa. Hold for 0.5 hours; then, cool to 450°C with the furnace, control the temperature accuracy at ±8°C, hold for 0.5 hours, and then cool to room temperature; open the furnace body to obtain a metallurgical bonded titanium-aluminum-stainless steel composite plate.

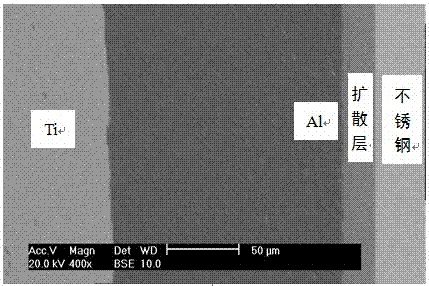

[0030] Figure 4 The cross-sectional morphology near the interface of the composite plate...

Embodiment 3

[0032] (1) Using 1mm thick TC4 titanium plate, 0.1mm thick pure aluminum foil and 8mm thick 316 stainless steel as raw materials, they were cut to a size of 50mm×50mm; the titanium surface was polished with sandpaper, and the stainless steel plate surface was removed by sandblasting. Oxide scale, etc., the aluminum plate is activated and cleaned by acid washing on the surface; then, it is combined in the order of titanium-aluminum-stainless steel and superimposed on 3 layers;

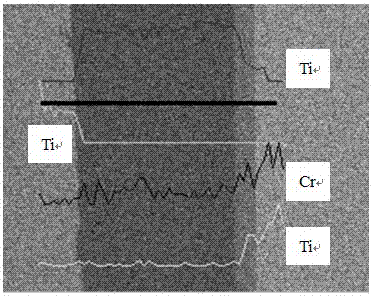

[0033] (2) Place the combined composite material in a vacuum hot-pressing device, pre-pressurize to 1Mpa, after vacuuming, heat to 600°C at a heating rate of 10°C / min, and then pressurize to a pressure of 2.5Mpa, Heat preservation for 2 hours; then, cool to 450°C with the furnace, control the temperature accuracy at ±8°C, hold for 0.8 hours, and then cool to room temperature; open the furnace body to obtain a metallurgical bonded titanium-aluminum-stainless steel composite plate. Figure 7 In this embodime...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com