Imitation rabbit hair chinlon 6 fiber and production method of imitation rabbit hair chinlon 6 fiber

A production method, the technology of imitating rabbit hair, applied in fiber processing, stretch spinning, melt spinning, etc., can solve the problems of difficult post-spinning processing, spinneret processing difficulty, etc., and achieve melt fine flow forming Good effect, good spinnability, good fluffy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

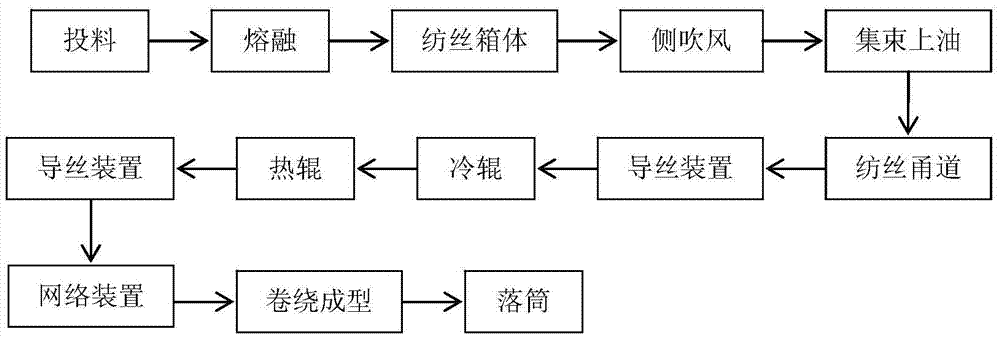

[0028] The production method of rabbit fur-like nylon 6 fiber with specifications 20D / 07F, monofilament fineness 2.9D, and flatness 6.0 is as follows, and the process flow refers to figure 1 .

[0029] (1) Put the fiber-grade full-dull nylon 6 slices with a relative viscosity of 2.47 and a moisture content of ≤320ppm into the hopper, heated and melted by the screw extruder, and sent to the spinning box through the melt distribution pipe. The temperature range of each zone of the screw extruder is 245, 250, 254, 256, 256°C

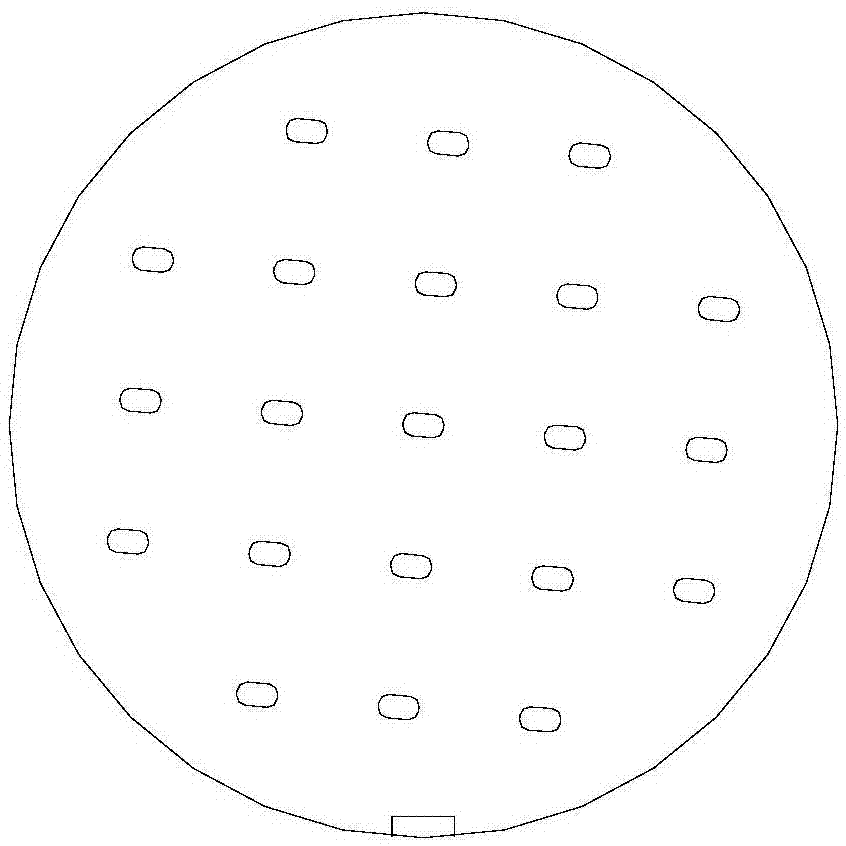

[0030] (2) The melt enters the spinning assembly in the spinning box and is sprayed out through the spinneret hole. The arrangement and shape of the spinneret holes are as follows: figure 2 and image 3 shown. The spinning assembly is equipped with five layers of filter screens, a layer of non-woven fabric and a certain proportion of mixed coarse and fine metal sand. The size of the coarse metal sand is 60-80 mesh, and the size of the fine metal sand ...

Embodiment 2

[0038] The production method of rabbit fur-like nylon 6 fiber with specification 40D / 07F, monofilament fineness 5.7D, and flatness 6.5 is as follows, and the process flow refers to figure 1 .

[0039] (1) Put fiber-grade full-dull nylon 6 slices with a relative viscosity of 2.47 and a moisture content of ≤370ppm into the feed bin, and be heated and melted by the screw extruder and sent to the spinning box through the melt distribution pipe. It is characterized by the temperature range of each zone of the screw extruder is 244, 248, 252, 254, 254°C

[0040] (2) The melt enters the spinning assembly in the spinning box and is sprayed out through the spinneret hole. The arrangement and shape of the spinneret holes are as follows: figure 2 and image 3 shown. The spinning assembly is equipped with five layers of filter screens, a layer of non-woven fabric and a certain proportion of mixed coarse and fine metal sand. The size of the coarse metal sand is 60-80 mesh, the size o...

Embodiment 3

[0048] The production method of rabbit fur-like nylon 6 fiber with specification 50D / 07F, monofilament fineness 7.1D and flatness 6.5 is as follows, and the process flow refers tofigure 1 .

[0049] (1) Put the fiber-grade full-dull nylon 6 slices with a relative viscosity of 2.47 and a moisture content of 470ppm into the silo, heat and melt by the screw extruder, and send them to the spinning box through the melt distribution pipe. It is characterized by the temperature range of each zone of the screw extruder is 243, 247, 250, 252, 252 °C

[0050] (2) The melt enters the spinning assembly in the spinning box and is sprayed out through the spinneret hole. The arrangement and shape of the spinneret holes are as follows: figure 2 and image 3 shown. The spinning assembly is equipped with five layers of filter screens, a layer of non-woven fabric and a certain proportion of mixed coarse and fine metal sand. The size of the coarse metal sand is 60-80 mesh, the size of the fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Breaking strength | aaaaa | aaaaa |

| Moisture content | aaaaa | aaaaa |

| Moisture content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com