Device and method for improving sensory quality of tobacco lamina fermented by biological enzyme

A post-fermentation, bio-enzyme technology, applied in tobacco, food science, tobacco preparation, etc., can solve the problems that the content of small molecule chemical substances affects the coordination of chemical components of tobacco leaves and the reduction of sensory quality, so as to improve the coordination of chemical components and improve Sensory quality, effect of enhancing use value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

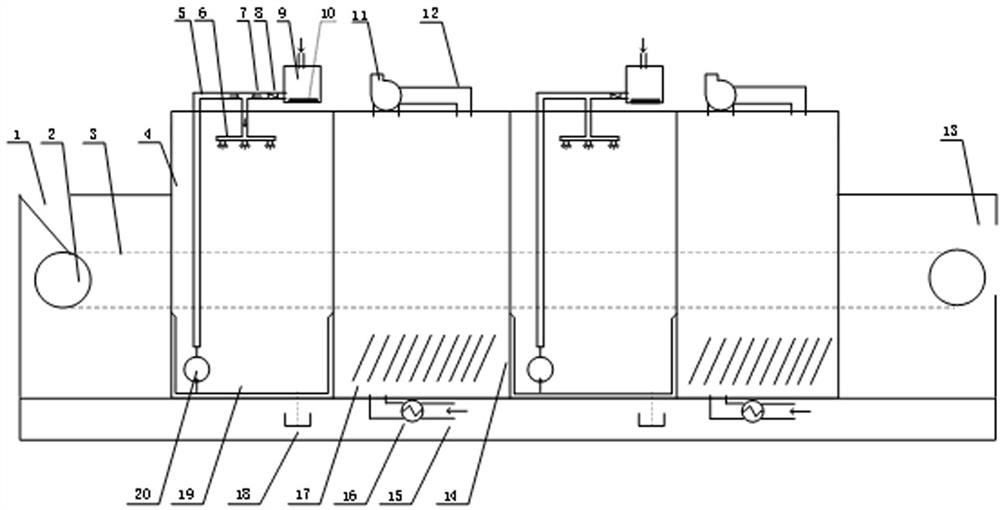

Image

Examples

Embodiment 1

[0033] The 2016 Henan Luoyang tobacco leaves stocked by a domestic cigarette industry enterprise, grade X4F, were processed by two methods, one is to use the existing bio-enzyme fermentation technology to process; the other is to use the existing bio-enzyme On the basis of fermentation technology, the device and method of the present invention are used for processing. The specific process is as follows:

[0034] Method 1: The 2016 Henan Luoyang sliced tobacco is sequentially processed by slicing, loosening, storing, bio-enzyme application, fermentation and inactivation. The bio-enzyme applied is composed of cellulase, amylase and protease to form a complex enzyme.

[0035] Method Two:

[0036] (1) The 2016 Henan Luoyang sliced tobacco was firstly processed through the existing bio-enzyme fermentation processes such as slicing, loosening, storage, bio-enzyme application and fermentation (the type of bio-enzyme applied is the same as method 1), and then passed through the ...

Embodiment 2

[0043] The 2015 Heilongjiang Suihua sheet cigarettes in stock of a domestic cigarette industrial enterprise, grade B4F, were processed by two methods, one is to use the existing bio-enzyme fermentation technology to process; the other is to use the existing bio-enzyme On the basis of fermentation technology, the device and method of the present invention are used for processing. The specific process is as follows:

[0044] Method 1: The 2015 Heilongjiang Suihua Tobacco was sequentially processed through the existing bio-enzyme fermentation technology such as slicing, loosening and re-moisture, storage, bio-enzyme application, fermentation and inactivation, and the bio-enzyme applied was cellulase.

[0045] Method Two:

[0046] (1) The 2015 Liaoning Dandong sliced tobacco was firstly processed through the existing bio-enzyme fermentation processes such as slicing, loosening, storage, bio-enzyme application and fermentation (the type of bio-enzyme applied is the same as metho...

Embodiment 3

[0053] The 2018 Hunan Shaoyang sheet cigarettes stocked by a domestic cigarette industrial enterprise are graded C4F. The sensory evaluation results show that the dry gas, woody gas and other miscellaneous gases are obvious, and the oral cavity is highly irritating and residual. After being treated with the existing biological enzyme fermentation technology, its dry coke gas and woody gas are slightly weakened, and the irritation of the mouth is also reduced, but the smoke tends to be flat. In order to further improve its quality, based on the existing biological enzyme fermentation technology On, adopt device and method of the present invention to process, concrete process is as follows:

[0054] (1) The 2018 Hunan Shaoyang sliced tobacco was firstly processed through the existing bio-enzyme fermentation processes such as slicing, loosening, storage, bio-enzyme application and fermentation. The applied bio-enzymes include cellulase, amylase, protease, Pectinase, etc.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com