Process for demetalizating of hydrocarbon oil

A technology for removing metal and hydrocarbon oil, which is applied in the field of removing metal calcium, magnesium and iron, and can solve problems such as secondary metal pollution of crude oil and equipment corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

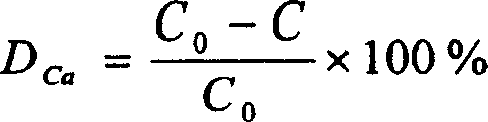

[0022] In this example, acetylacetone was used to remove metallic calcium.

[0023] The oil used in the experiment was crude oil processed by a refinery in Xinjiang (referred to as Xinjiang crude oil), with a calcium content of 40.9ppm, an iron content of 3.23ppm, and a magnesium content of 0.96ppm. Acetylacetone is a commercially available reagent of analytical grade.

[0024] Weigh a certain amount of Xinjiang crude oil and put it into a beaker, add acetylacetone and water according to a certain dose-to-calcium ratio and a water injection rate of 20%. Preheat to 80°C temperature. Use a mixer to mix oil, water and demetallizer for 15 minutes to form an oil-water emulsion. After the end, pour the oil-water mixture into the desalting bottle, add 50ppm demulsifier, put it into the DPY-2 demulsification and electric dehydration performance tester, and stand still for 1 hour under the condition of temperature 80°C and electric field 2000V to completely separate oil and water . ...

Embodiment 2

[0029] In this example, acetylacetone was used as the demetallization agent. Taking Xinjiang crude oil as the experimental oil, under the conditions of 2.5 doses of calcium molar ratio and 20% water injection rate, the test method is the same as that of Example 1, and the results are listed in Table 2.

[0030] It can be seen from the results in Table 2 that acetylacetone has a good demetallization effect when the mixing time is in the range of 5-30 minutes and the mixing temperature is in the range of 30-80°C.

[0031] temperature, ℃

Embodiment 3

[0033] In this example, acetylacetone was used as the demetallization agent. Taking Shengli crude oil as the experimental oil (calcium content 32.3ppm, iron content 9.59ppm, magnesium content 2.51ppm), under the conditions of 2.5 metal molar ratios and 20% water injection rate, the test method is the same as in Example 1, and the results are listed in the table 3.

[0034] It can be seen from the results in Table 3 that acetylacetone not only has a good decalcification effect, but also has a good deferrification and magnesium removal effect.

[0035]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com