Low radiation glass capable of being post-treated and its production process

A technology of low-emissivity glass and manufacturing method, which is applied in sputtering coating, metal material coating process, ion implantation coating, etc., can solve the problems of high glass transportation cost, long patch cycle, and inability to coat, etc., to meet the requirements of Long-distance transportation, stable optical performance, and various colors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

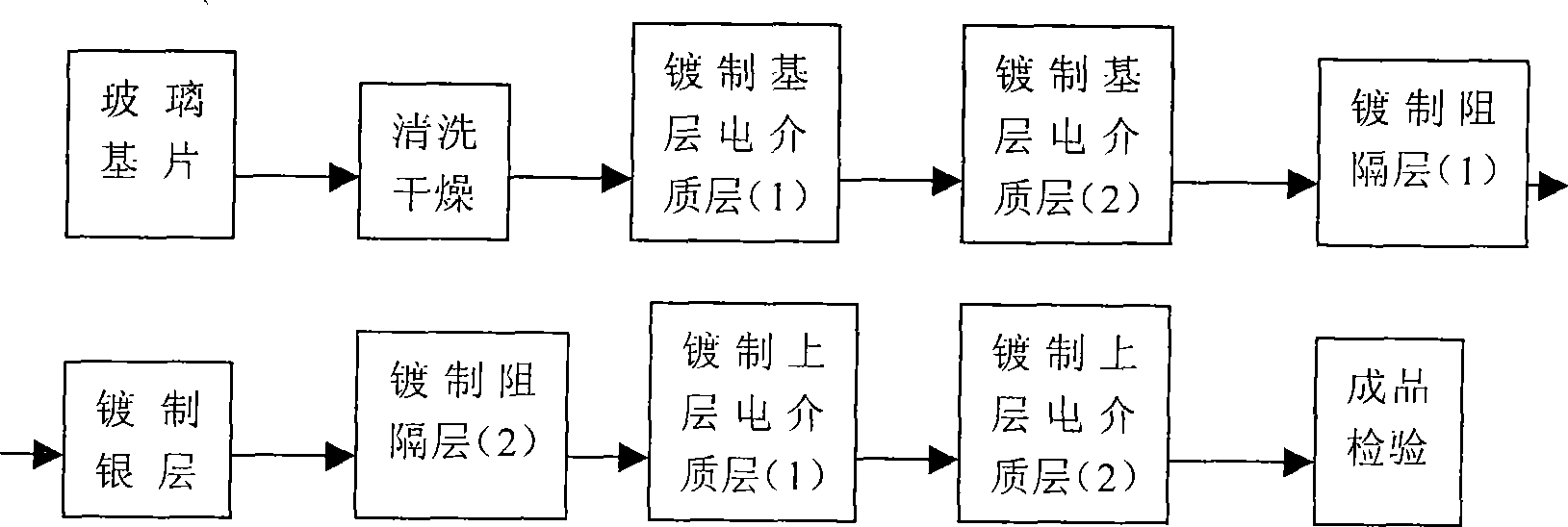

[0031] Embodiment: Referring to the accompanying drawings, the manufacturing method of the low-emissivity glass that can be processed later in the present invention firstly cleans and dries the glass substrate, and then adopts the vacuum magnetron sputtering coating process, and configures a high-speed non-conductive glass in the coating line. Oil molecular pump, background vacuum in high vacuum 3*10 -6 mbar or above, and plated on glass according to the following steps:

[0032] 1. Coating silicon nitride (SiN) on the glass surface 3 N 4 ) base layer dielectric composite film layer (1), sputter deposition in an argon-nitrogen atmosphere with an intermediate frequency power supply and rotation, the power is 85kw, the frequency of the intermediate frequency power supply is 40kHz, and the thickness of the film layer is 37nm;

[0033] 2. Silicon nitride in glass (Si 3 N 4 ) base dielectric combination film (1) is plated with zinc tin oxide (ZnSnOx) base dielectric combination...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com