Shape correcting device of high temperature alloy split-opened casing and correcting method of shape correcting device

A technology of paired open case and high-temperature alloy, which is applied in the field of large-scale open case processing, can solve the problems that the case is difficult to form a good calibration effect and the plastic deformation of the case, so as to enhance the rigidity, simplify the difficulty and improve the processing quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

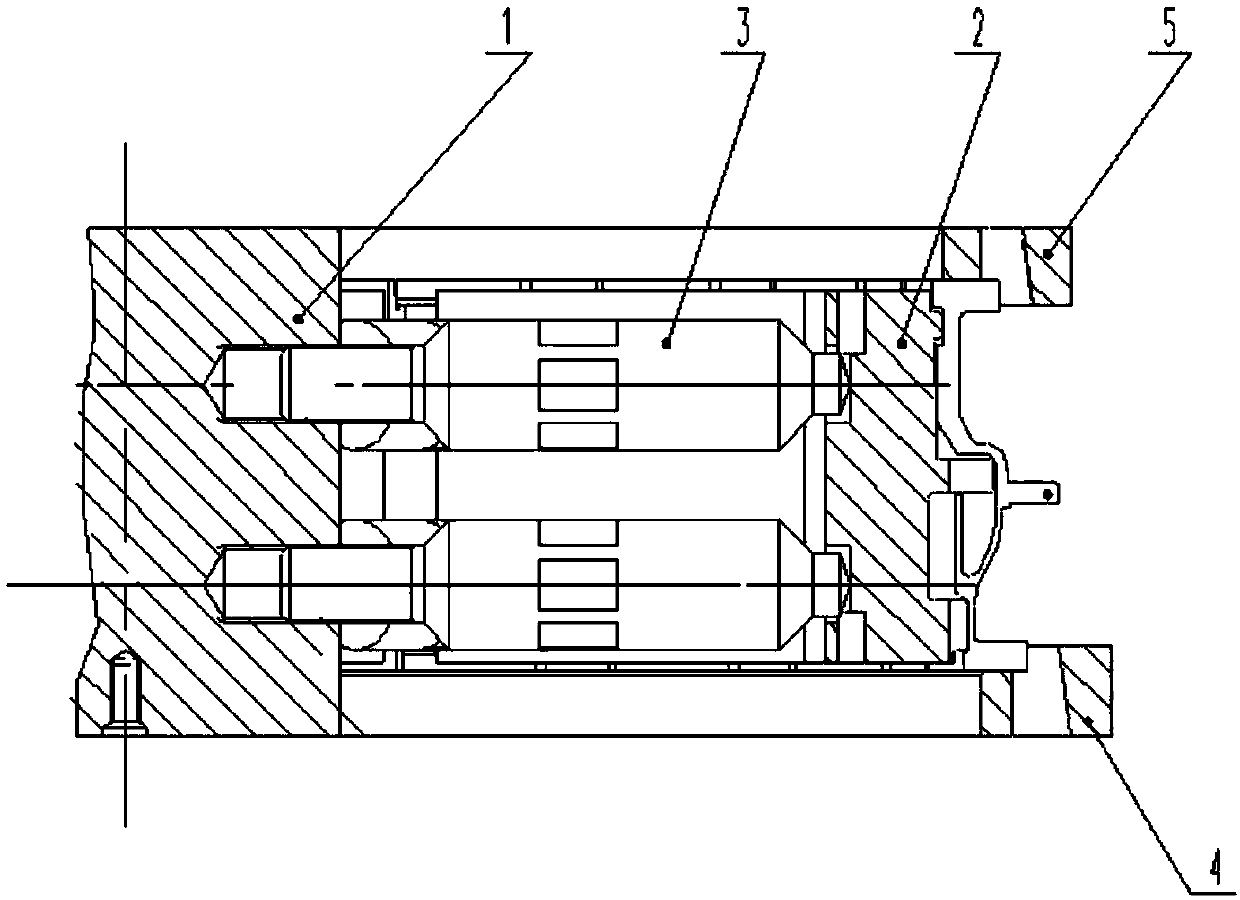

[0076] The first shape correcting ring 4 is a ring structure, and the inner side of the end face is provided with a spigot, and the diameter of the spigot is the same as the outer circle of one end of the casing mounting edge. There is a gap of 0.5mm; the end face of the first shape correction ring 4 is provided with a wedge-shaped square groove; the material is austenitic stainless steel 1Cr18Ni9Ti.

[0077] The second external shape correction ring 5 is a circular ring structure, and there is a spigot on one end surface, and the diameter of the spigot is the same as the outer circle of the other end of the casing installation edge. There is a gap of 0.6 mm; the end face of the second shape correction ring 5 is provided with a wedge-shaped hole, and its material is austenitic stainless steel 1Cr18Ni9Ti.

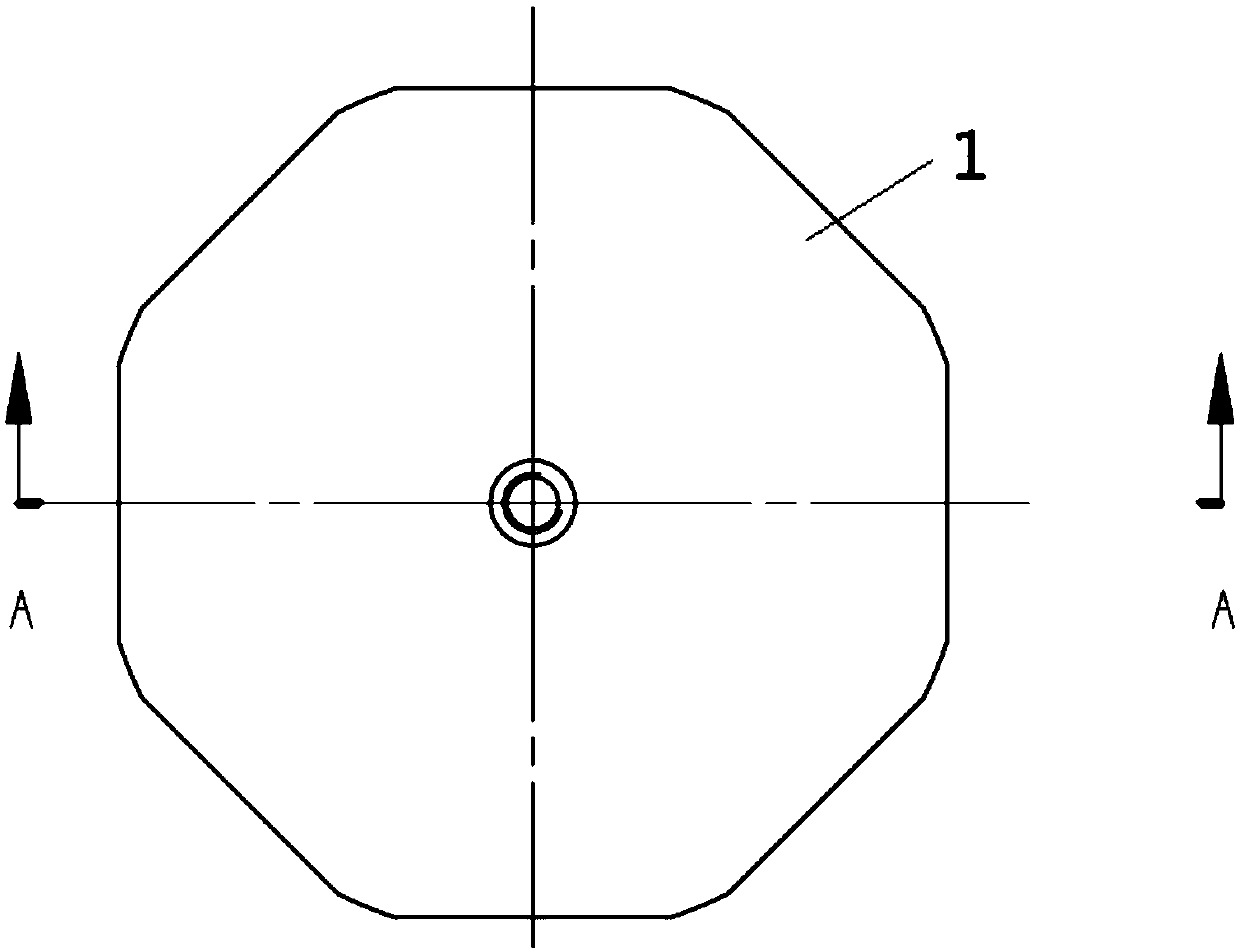

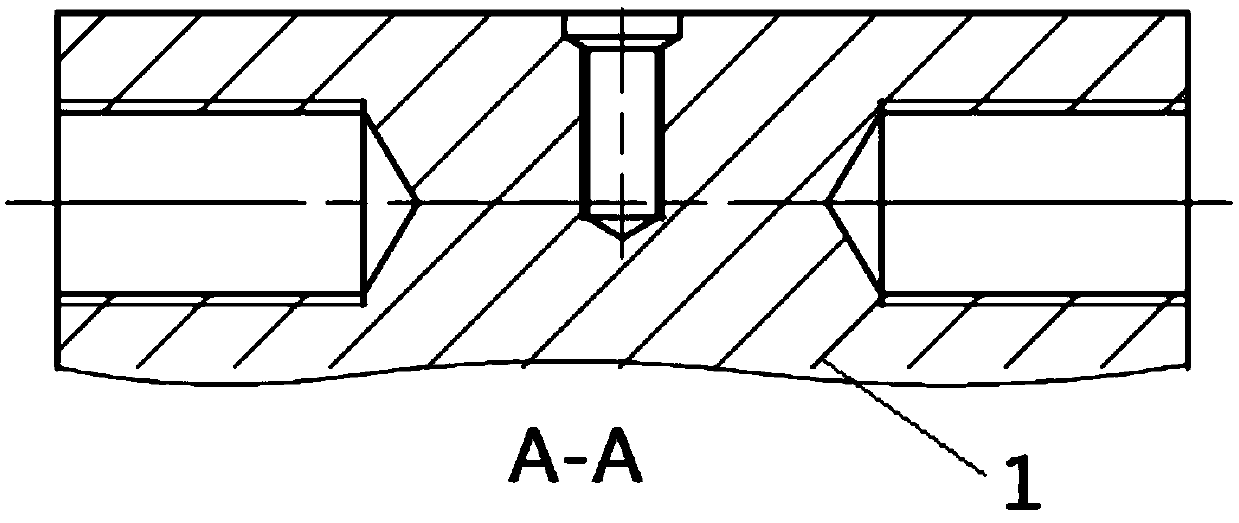

[0078] The height of mandrel 1 is the same as that of the casing to be calibrated. Eight groups of evenly distributed threaded holes are opened on the outer circumference ...

Embodiment 2

[0095] Step 1, detect the corresponding size of the left and right halves of the open case is the upper end The theoretical value is 657mm, the measured value is 656.2mm, 656.4mm, the lower end The theoretical value is 673.5mm, and the measured values are 673.38mm and 673.2mm.

[0096] Step 2, detecting the diameter of the designated position of the casing in the direction of 90° to the joint surface, and calculating the approximate ellipticity of the part. The corresponding dimensions of the detection paired open box are: upper end The theoretical value is 657mm, the measured value is 657mm, the lower end The theoretical value is 673.5mm, the measured value is 673.96mm, and the ellipticity of the part is 0.8mm~1mm.

[0097] Step 3: Calibrate the two halves of the casing with the shape correction ring to ensure that the end face of the correction ring fits the upper and lower end faces of the casing.

[0098] Step 4: Place the paired open case with the shape correcti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Eccentricity | aaaaa | aaaaa |

| Eccentricity | aaaaa | aaaaa |

| Eccentricity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com