A method and system for synergistic sludge dewatering treatment of aged leachate in a landfill

A technology for landfill and sludge dewatering, applied in water/sludge/sewage treatment, sludge treatment, dehydration/drying/concentrated sludge treatment, etc. Difficulty in filtrate treatment, increase in ash content in sludge, etc

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

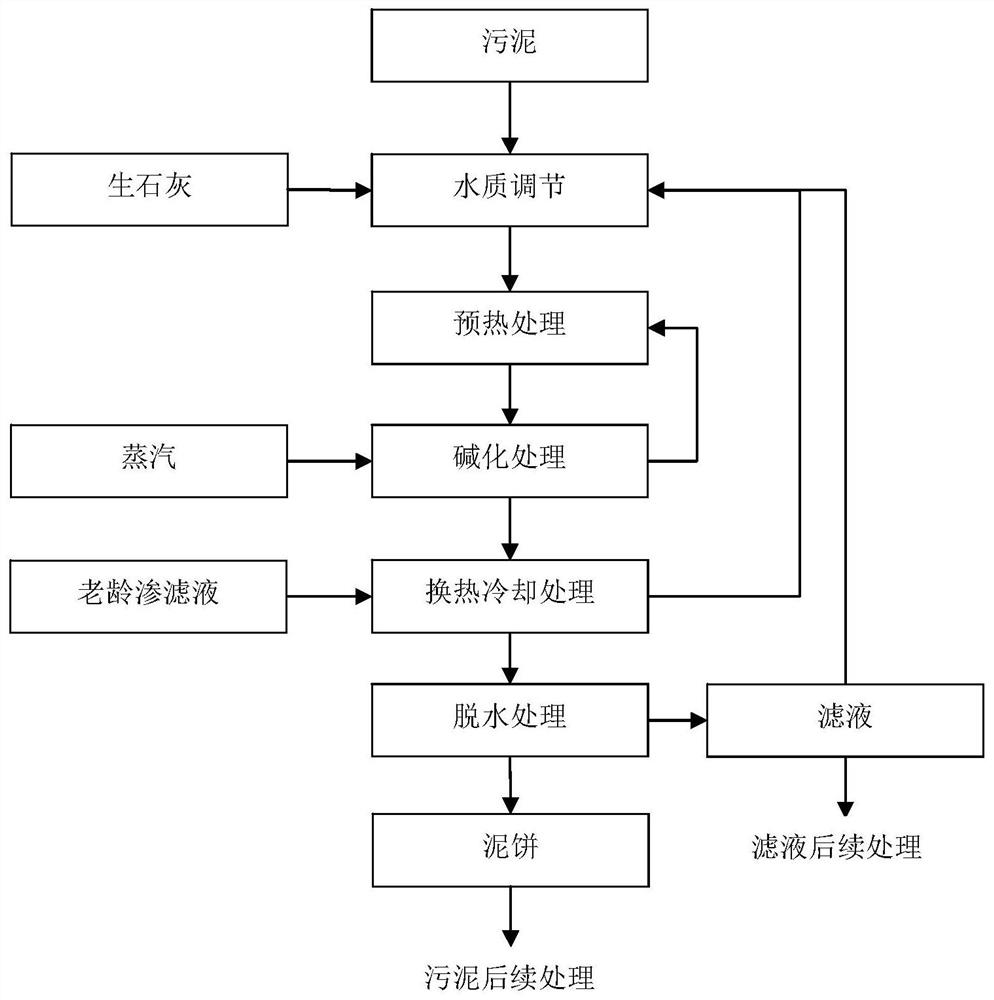

[0032] A method for synergistic sludge dewatering treatment of aged leachate in a landfill, the treatment flow chart is as follows figure 1 shown, including the following steps:

[0033] (1) The municipal sludge with a moisture content of 80% is transported to the sludge storage silo, and the mass ratio is 1:1, and the sludge and the old leachate are transported to the adjustment tank for water quality adjustment. The sludge is diluted, and then quicklime is added, wherein the amount of quicklime added is 1.5% of the total mass of the sludge and the aged leachate, and the sludge is uniformly mixed to obtain the sludge containing aged leachate and alkali.

[0034] (2) the sludge containing the aged leachate and alkali obtained in the step (1) is transported to the preheating device for preheating treatment, specifically: opening the inner paddle agitator, under the stirring speed of 120rpm, using the pressure The sludge is heated to 60°C with saturated or superheated steam of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com