Tea tree transplanting equipment

An equipment and technology for tea trees, applied in the field of tea tree transplanting equipment, can solve the problems of time-consuming and labor-intensive, large force on the rotating knife and high power demand, and achieve the effects of good removal effect, easy transplanting and good protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

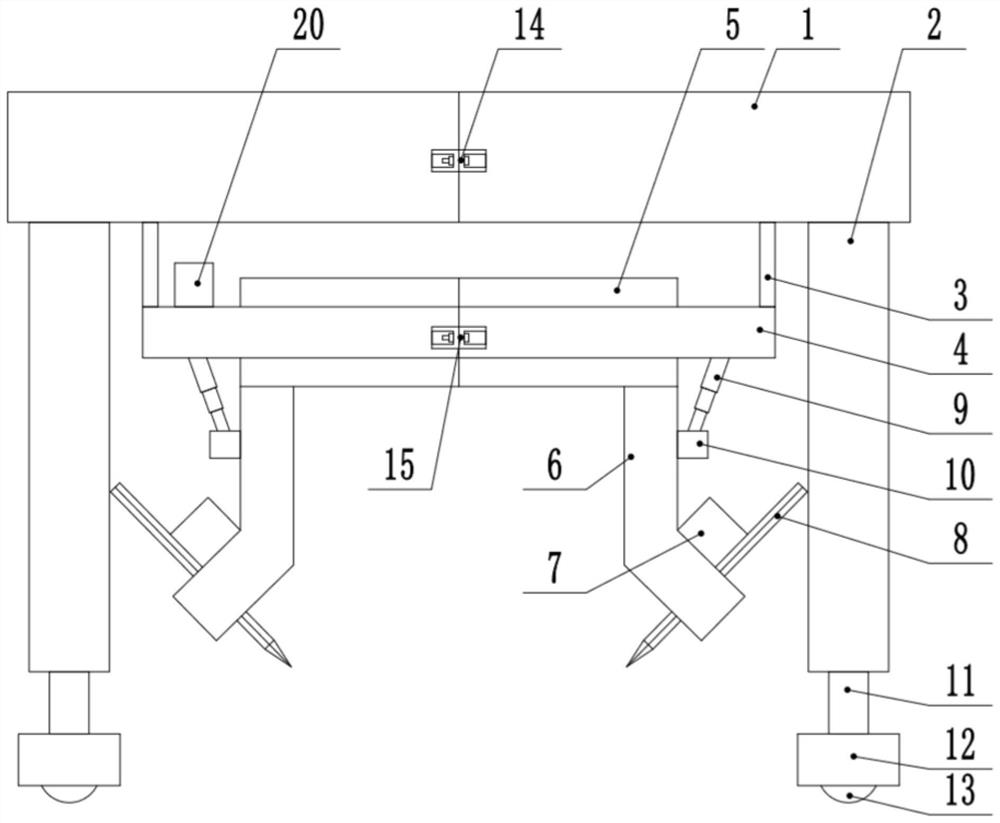

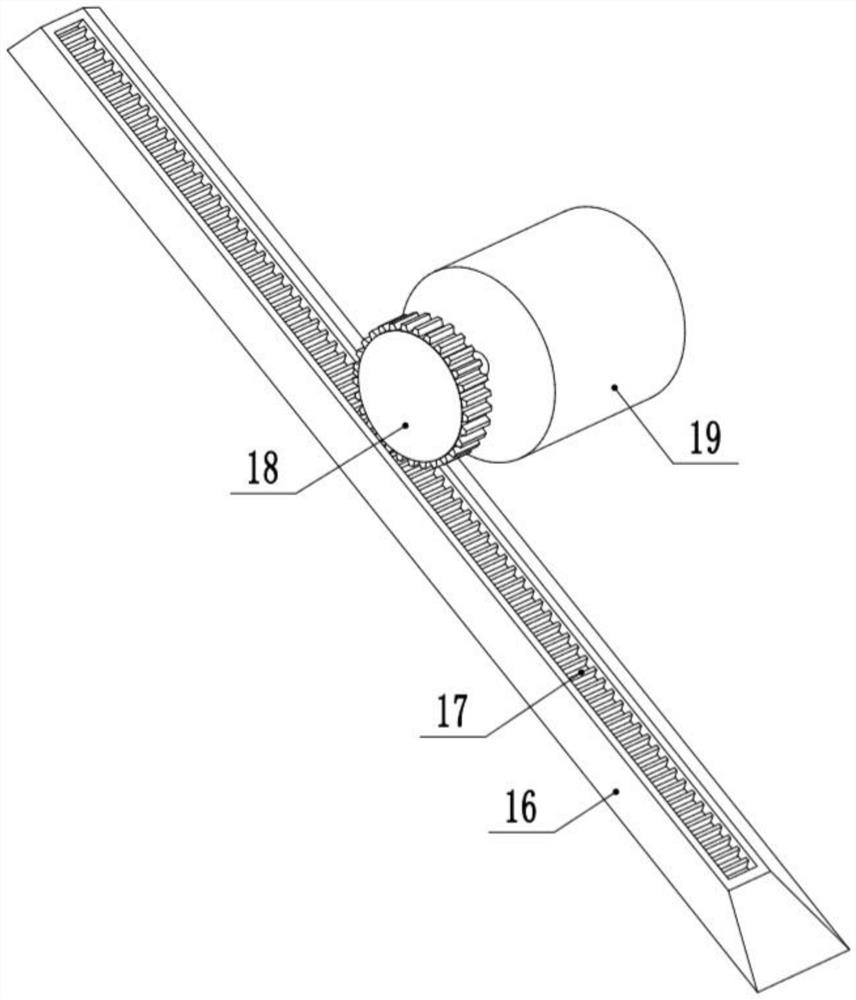

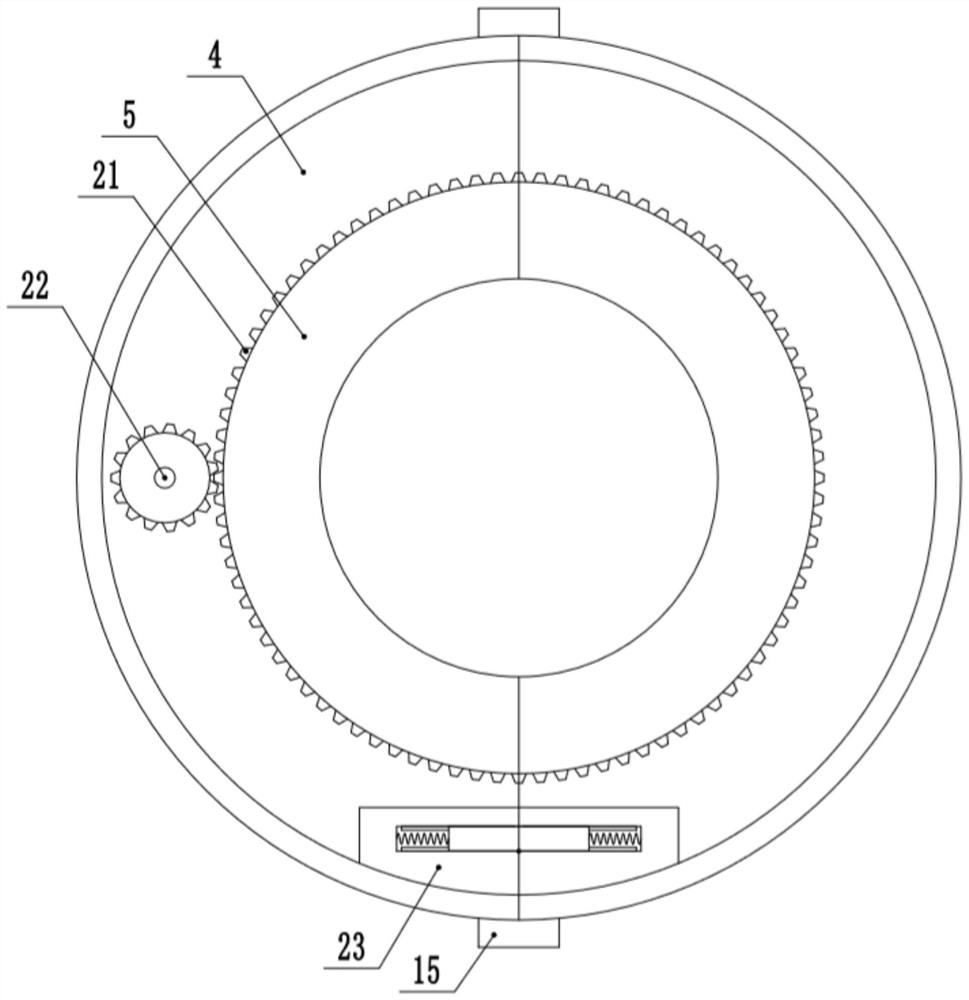

[0025] see Figure 1-4 , a kind of tea tree transplanting equipment, comprises top frame 1, and the bottom of top frame 1 is fixedly connected with a plurality of supporting legs 2, is characterized in that, the bottom end of each top frame 1 is all fixedly connected pull-down rod 3, and The bottom end of the pull rod 3 is fixedly connected with the fixed sleeve 4, and the inner rotation of the fixed sleeve 4 is connected with the rotating base 5, and the bottom of the rotating base 5 is connected with an underframe 6, and the underframe 6 is provided with a driving device 7 and a shoveling device 8. The bottom of the supporting leg 2 is provided with a lifting and moving device.

[0026] Described elevating moving device comprises the bottom groove that offers at the bottom of supporting leg 2, and telescopic leg 11 is fixedly arranged in the bottom groove, and the bottom end of telescopic leg 11 is fixedly connected footing 12, and the bottom end of footing 12 is rotatably c...

Embodiment 2

[0036] see Figure 1-4 , the other content of this embodiment is the same as that of Embodiment 1, the difference is:

[0037] In the implementation process of the present invention, the two top frames 1 are pulled to separate, then the two top frames 1 are rotated, and the rotating plate 26 is rotated simultaneously, and then the device is moved to the vicinity of the tea tree so that the two top frames 1 are positioned at the two ends of the tea tree. side, then loosen the top frame 1, and under the reset action of the spring 27, the two top frames 1 are combined, and the top frame 1 and the fixing sleeve 4 are respectively fixed by the first connecting device 14 and the second connecting device 15, and then according to The size of the tea tree plant is controlled by the expansion and contraction of the hydraulic telescopic rod 9 to adjust the direction of the knife plate 16. After the adjustment is completed, start the first drive motor 19 and the second drive motor 20, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com