Method for breaking concrete pile head

A technology of concrete and pile heads, which is applied in construction, sheet pile walls, foundation structure engineering, etc., can solve the problems of manpower and material resources, slow construction speed, complicated process, etc., and achieve the effects of cost saving, convenient removal and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

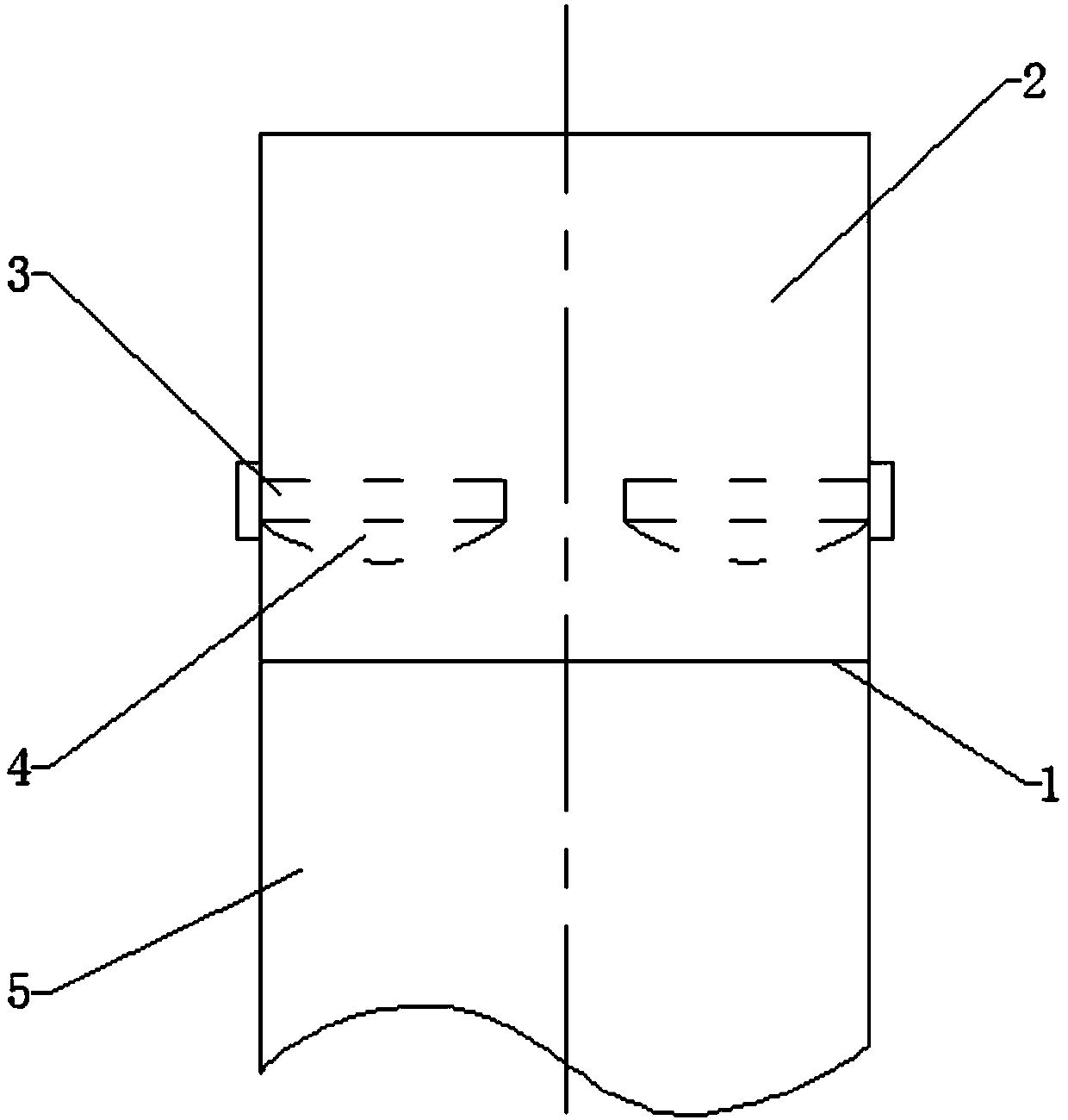

[0044] According to one embodiment, the drilling direction can be at a certain angle with the horizontal direction, such as -30° drilling with the horizontal direction (that is, drilling in a direction 30° below the horizontal line), or -60° drilling with the horizontal direction ( That is, drilling in the direction of 60° below the horizontal line), another example is drilling at 30° to the horizontal direction (that is, drilling in the direction of 30° above the horizontal line), or drilling at 60° in the horizontal direction (that is, drilling in the direction of 60° above the horizontal line) drilling), the present invention is not limited thereto.

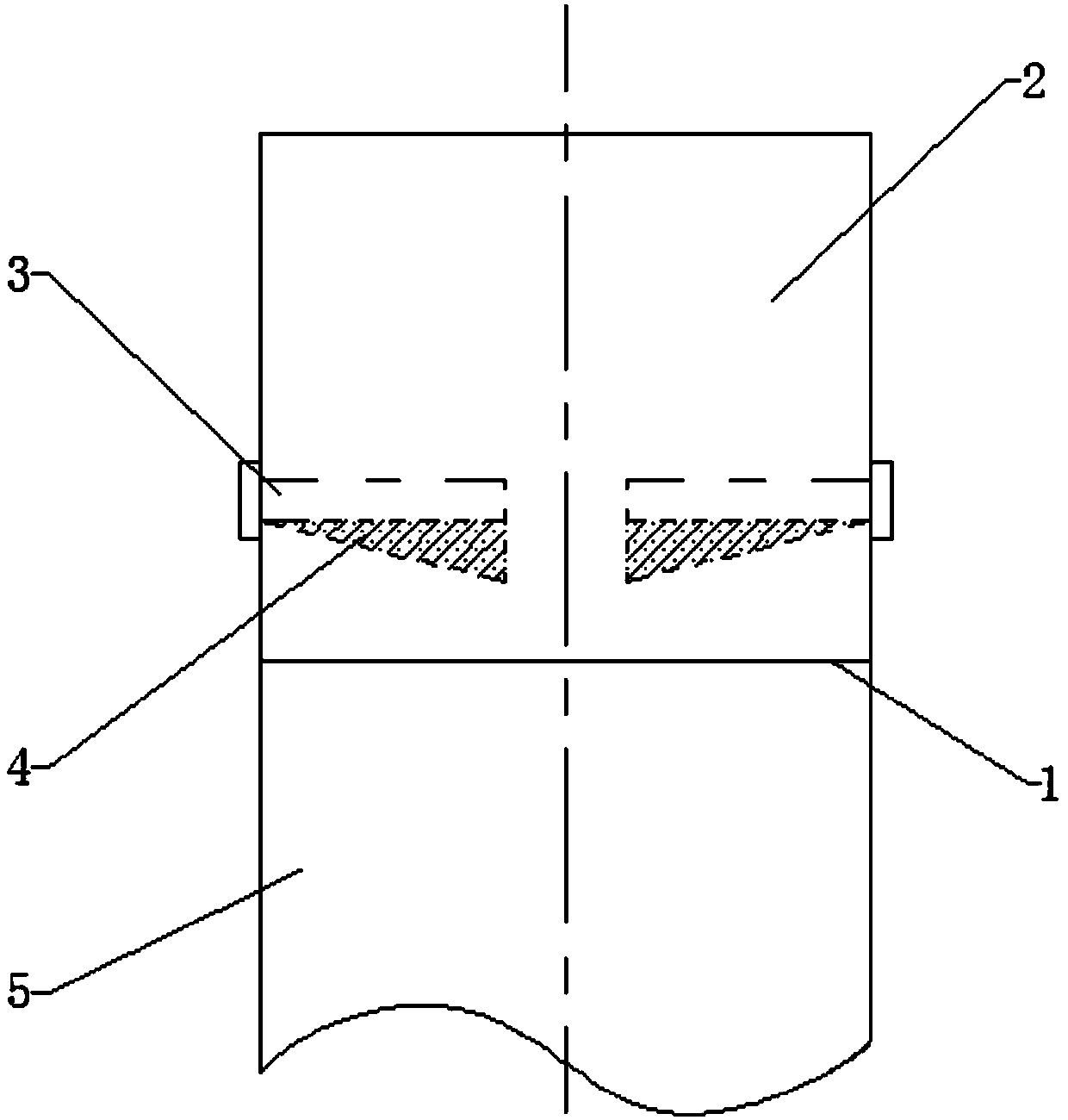

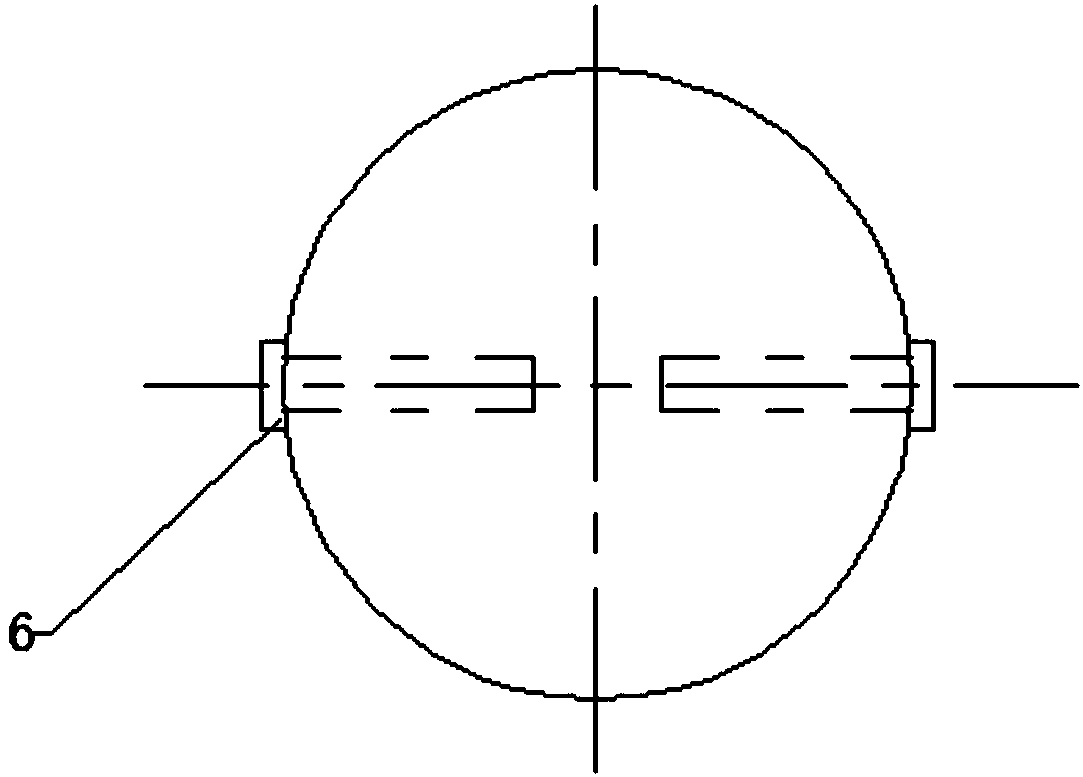

[0045] In step 3), if figure 1 As shown, at least one cavity 4 is formed in the tunnel 3 by expanding from the inner cavity of the tunnel 3 .

[0046] Excavating from the inner cavity of the channel 3 to the inner wall of the channel 3 to form a cavity 4, according to one embodiment, for example, can be expanded from the inne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com