Efficient and energy-saving extraction tank

A high-efficiency, energy-saving, extraction tank technology, applied in solid solvent extraction, chemical instruments and methods, solvent extraction, etc., can solve the problems of small capacity of appliances, energy consumption and man-hours, limited scope of action, etc., to improve efficiency and reduce operation. Cost, energy saving and man-hour effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

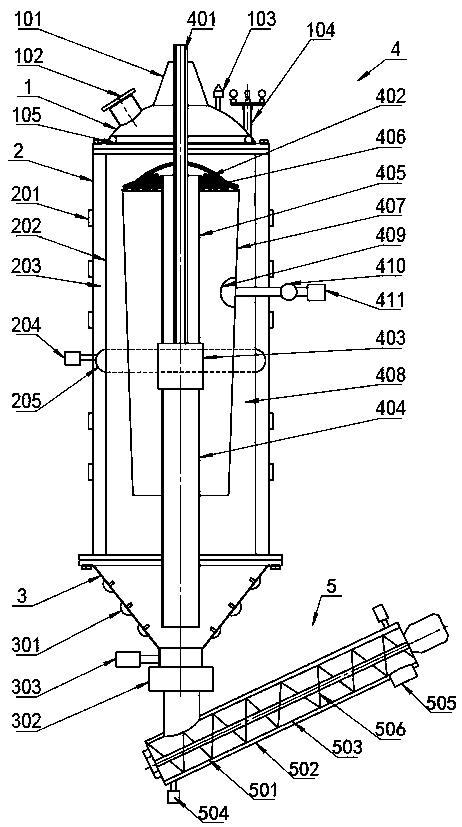

[0022] Example 1, using microwave and ultrasonic to extract chestnut bract brown pigment.

[0023] Chestnut buds are crushed to 60 mesh, put into the tank together with deionized water according to the solid-liquid ratio of 1: 10 (by mass), start the slurry pump 403 to rotate forward, and the slurry mixed with solid and liquid in the tank is sucked into the lower port of the suction pipe 404 Then, the upper port of the lift pipe 405 diffuses into the bamboo hat-shaped sieve plate 406, during which the liquid solvent in the slurry is filtered out from the large number of mesh holes in the lift pipe and the sieve plate, and reversely flows into the isolation cylinder 407. Downward, while the solid material is driven down by the continuously rotating scraper 402 on the sieve plate into the channel 408 on the periphery of the isolation cylinder. When the suction nozzle at the bottom of the tank is sucked into the channel, it goes up again, and after being filtered and separated, t...

example 2

[0028] Example 2, chestnut bract tannins were extracted using steam and ultrasonic waves.

[0029] The first step of moisturizing and fabric is exactly the same as Example 1. In the second step, because the pharmaceutical industry does not allow the use of microwaves to heat medicinal materials, microwaves are not used, and steam is used as a heat source to heat and break the solid material. Specifically, the tank is adjusted. The pressure regulating valve 103 on the cover controls the air pressure in the tank below 0.04Mpa, opens the steam valve 204 and the ultrasonic generator, and the pressure steam in the steam ring pipe 205 enters the channel filled with solid through the uniformly distributed air holes on the ring pipe Inside, continuously fumigate the descending solid material to cause it to expand and break the wall due to heat, during which the steam squeezes out the gap between the solid material due to air pressure, continuously rises to the top of the tank, and is r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com