Ultra-coarse-denier flat nylon 6 filament and method for producing the same

A production method and technology of flat filaments, which are applied in the production field of nylon 6 ultra-coarse denier flat filaments and ultra-coarse denier nylon 6 flat filaments, can solve the problems such as there is no suitable preparation method for ultra-coarse denier nylon 6 flat filaments, and achieve technological advancement Content and added value, stable production process, and high product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

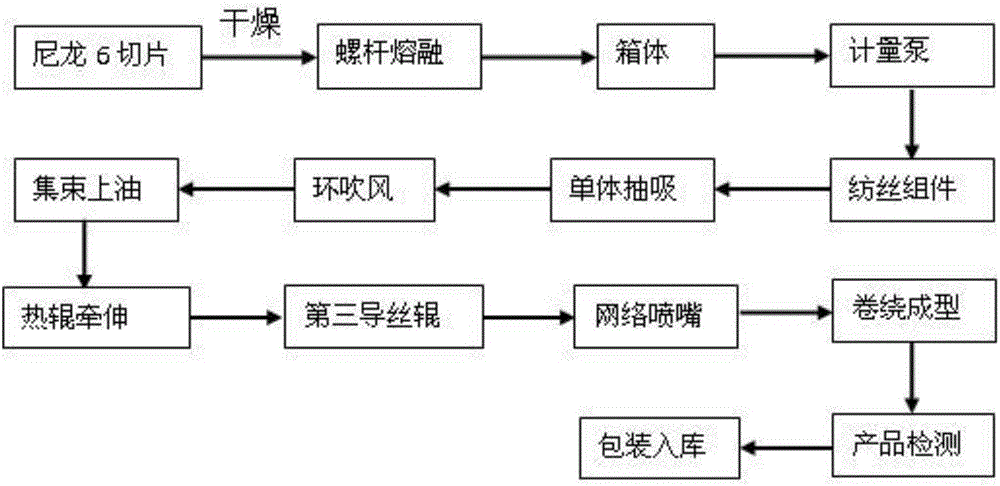

[0018] Such as figure 1 Shown: Melt-spin the dried 6-slice resin, the slice viscosity is 2.48, and the melting point is 219°C. The nylon 6-slice melt is extruded through a screw extruder and sent to the box, and the melt is quantitatively compressed by a metering pump. into the spinning assembly. Among them, the temperature of each zone of the melt in the screw extruder is 257°C, 262°C, 262°C, 262°C respectively, and the spinning temperature is 262°C; 1.5mm×0.17mm, the hole depth is 0.8mm, and the number of holes is 24. The nylon 6 melt is extruded in a filament state through the spinneret holes on the spinneret plate, and then sucked by the monomer, and then enters the inner ring blowing device for cooling , the speed of the surrounding air blowing is 0.6m / s, the temperature of the cooling air is controlled at 19°C, and the humidity is controlled at 75%. The final tow is bundled by two oilings, the bundle point is 135cm away from the spinneret, and the oil concentration is ...

Embodiment 2

[0020] Such as figure 1 Shown: Melt spinning the dried 6-slice resin, the viscosity of the slice is 2.47, and the melting point is 218°C. The melted nylon 6 slices are extruded by a screw extruder and sent to the box, and the melt is quantitatively compressed by a metering pump. into the spinning assembly. Among them, the temperature of each zone of the melt in the screw extruder is 256°C, 259°C, 259°C, 259°C respectively, and the spinning temperature is 259°C; 2.0mm×0.20mm, the hole depth is 0.8mm, and the number of holes is 18. The nylon 6 melt is extruded in a filament state through the spinneret holes on the spinneret plate, and then sucked by the monomer, and then enters the inner ring blowing device for cooling , the speed of the surrounding air blowing is 0.6m / s, the temperature of the cooling air is controlled at 18°C, and the humidity is controlled at 80%. The final tow is bundled by two oilings, the bundle point is 145cm away from the spinneret, and the oil concent...

Embodiment 3

[0022] Such as figure 1 Shown: Melt spinning the dried 6-slice resin, the viscosity of the slice is 2.47, and the melting point is 218°C. The melted nylon 6 slices are extruded by a screw extruder and sent to the box, and the melt is quantitatively compressed by a metering pump. into the spinning assembly. Among them, the temperature of each zone of the melt in the screw extruder is 254°C, 257°C, 257°C, 257°C respectively, and the spinning temperature is 257°C; 3.0mm×0.30mm, the hole depth is 2.0mm, and the number of holes is 12. The nylon 6 melt is extruded in a filament state through the spinneret holes on the spinneret plate, and then sucked by the monomer, and then enters the inner ring blowing device for cooling , the speed of the surrounding air blowing is 0.7m / s, the temperature of the cooling air is controlled at 17°C, and the humidity is controlled at 80%. After the tow is oiled and bundled in two stages, the bundle point is 170cm away from the spinneret, the concen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com