Production formula for solving easy precipitation in rigid polyvinyl chloride pipe production and pipe preparation process thereof

A technology for production formula of hard polyvinyl chloride, which is applied in the field of improving the production formula of hard polyvinyl chloride pipes that are easy to precipitate and the production process of the pipes, and can solve the problems of low compatibility and difficult quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A preparation method of rigid polyvinyl chloride pipe, comprising the steps of:

[0040] A. Taking materials: Weigh each component in the formula:

[0041] B. High-speed hot stirring: Add each component in the formula to the mixer, heat each component in the formula to 110-130 degrees Celsius, and start the mixer at the same time, the rotating speed of the drum in the mixer is 400-600r / min The time is 10-25mins

[0042] C. Low-speed cold stirring: reduce the rotating speed of the drum to 120-140r / min. At the same time, cool down the mixed components after stirring to 35-45 degrees Celsius, and the stirring time is 15-30mins

[0043] D, leave standstill: after each component mixes uniformly, leave standstill 5-8h to obtain mixing;

[0044] E, forming: the mixed material is transported to the extruder through the feeding system for extrusion processing, cooling and shaping and cutting into pipes;

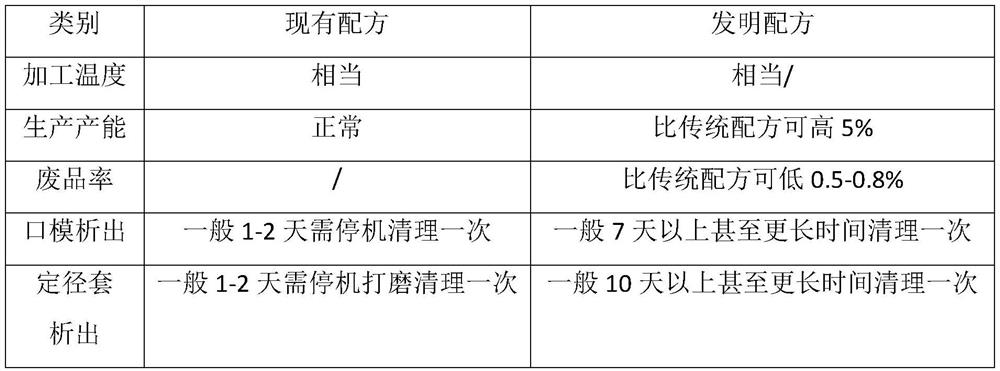

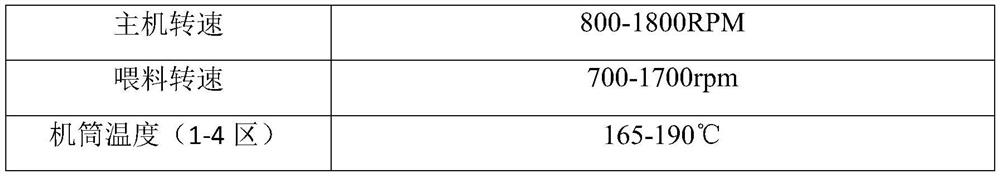

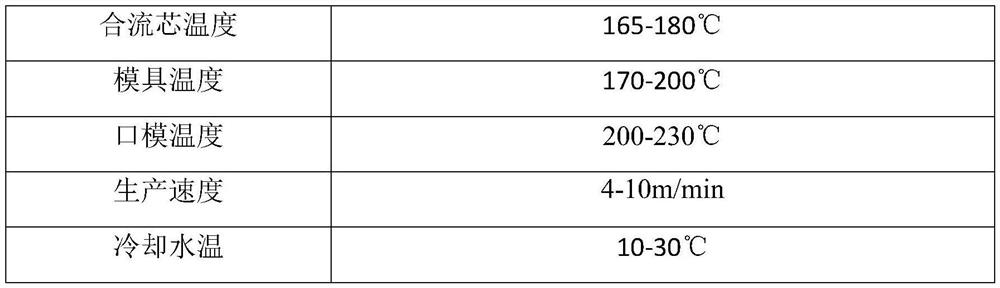

[0045] F. Extrusion process control: Hebei Wen'an Tongda Plastic Machiner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com