Thread propelling type manual clothes dewatering barrel

A threaded propulsion and dewatering barrel technology, applied in washing devices, textiles and papermaking, household appliances, etc., can solve the problems of discoloration, inability to machine wash, mildew and other problems of clothes, so as to reduce the problem of deformation and discoloration, reduce workload, and improve protection. effect of action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with accompanying drawing:

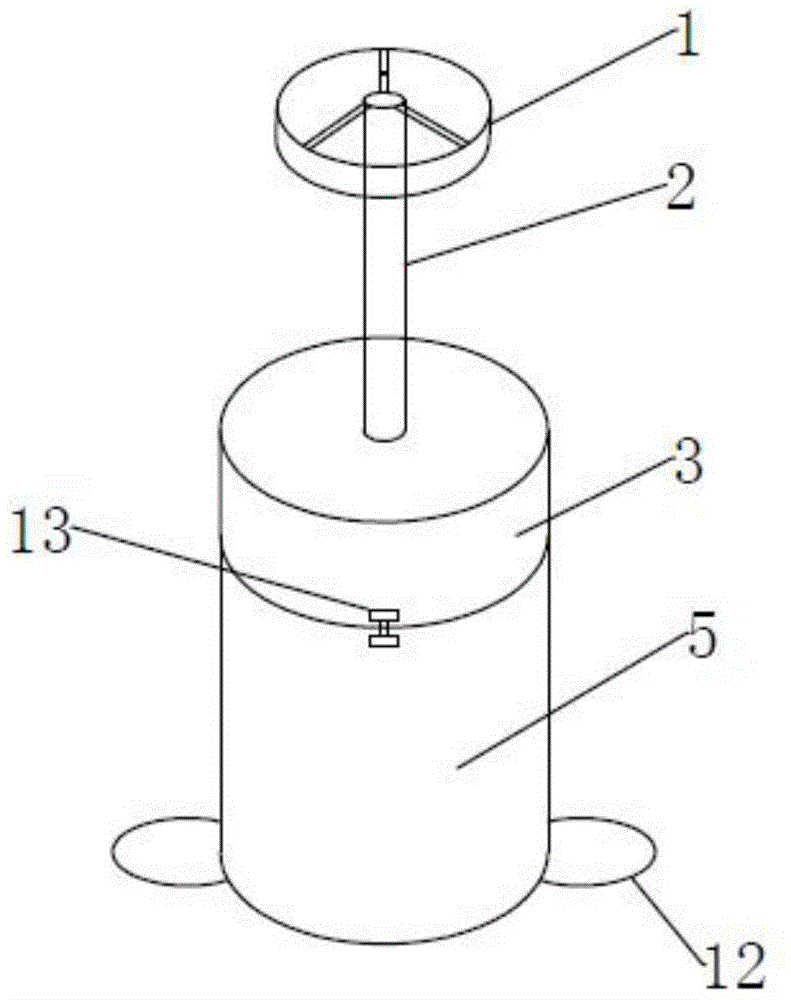

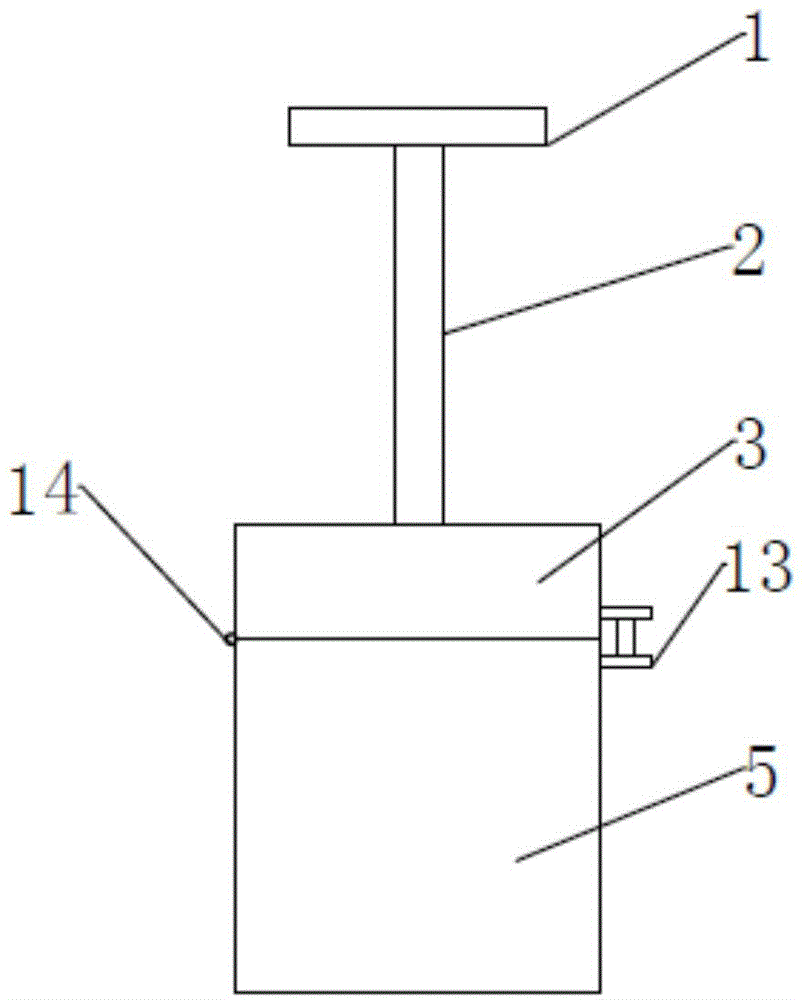

[0025] see Figure 1 to Figure 4 , the present invention includes a dehydration bucket 5 and a bucket cover 3, the bucket cover 3 is arranged above the dehydration bucket 5 through a connecting piece 14, and the bucket cover 3 can rotate around the connecting piece 14, and the bucket cover 3 and the dehydration bucket 5 are provided with Switch 13 is provided with drainage groove 6 at the inner bottom of dehydration bucket 5 buckets, and is provided with drainage slope 7 below the drainage groove 6, and drainage slope 7 can collect and discharge the water flow rapidly.

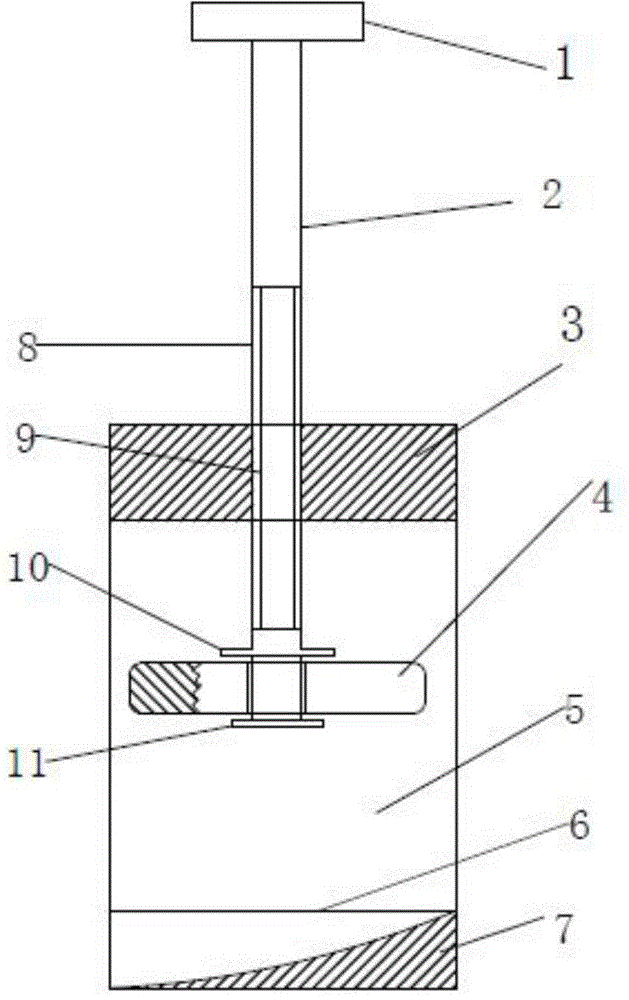

[0026] An internally threaded hole 9 is provided on the bung 3, and a rotating rod 2 is installed in the internally threaded hole 9, and the middle part of the rotating rod 2 is provided with an external thread 8 screwed with the internally threaded hole along its axial direction, when the rotatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com