Method for deep dehydration of residual activated sludge

A residual active, deep dewatering technology, applied in dewatering/drying/concentrating sludge treatment, preparation of organic fertilizers, organic fertilizers, etc. The equipment requirements are not high, and the effect of promoting development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Collect 100kg of residual activated sludge through mechanical dehydration, put it in a 500L reaction tank, add 20L of waste gulonic acid mother liquor (weight is 26-27 kg, wherein short-chain organic acids account for 60wt%), stir evenly, make it in slurry state, Heat the tank to 90°C, keep it warm for 1 hour, export the reaction solution to a water tank, add 10kg of corncob crumbs, stir evenly until it becomes thick sauce, move it into a ventilated oven and bake at 100°C for 6 hours to make dry sludge, sludge The water content of the mixture is 18wt%.

[0017] In this embodiment, the guaronic acid mother liquor is one or more mother raffinate left after extracting gulong acid crystals in the production of Vc. In terms of weight percentage, the main composition of the short-chain organic acid in the guaronic acid mother liquor is as follows: 20% guaronic acid, 40% formic acid, 10% oxalic acid, 15% propionic acid and 15% butyric acid.

Embodiment 2-5

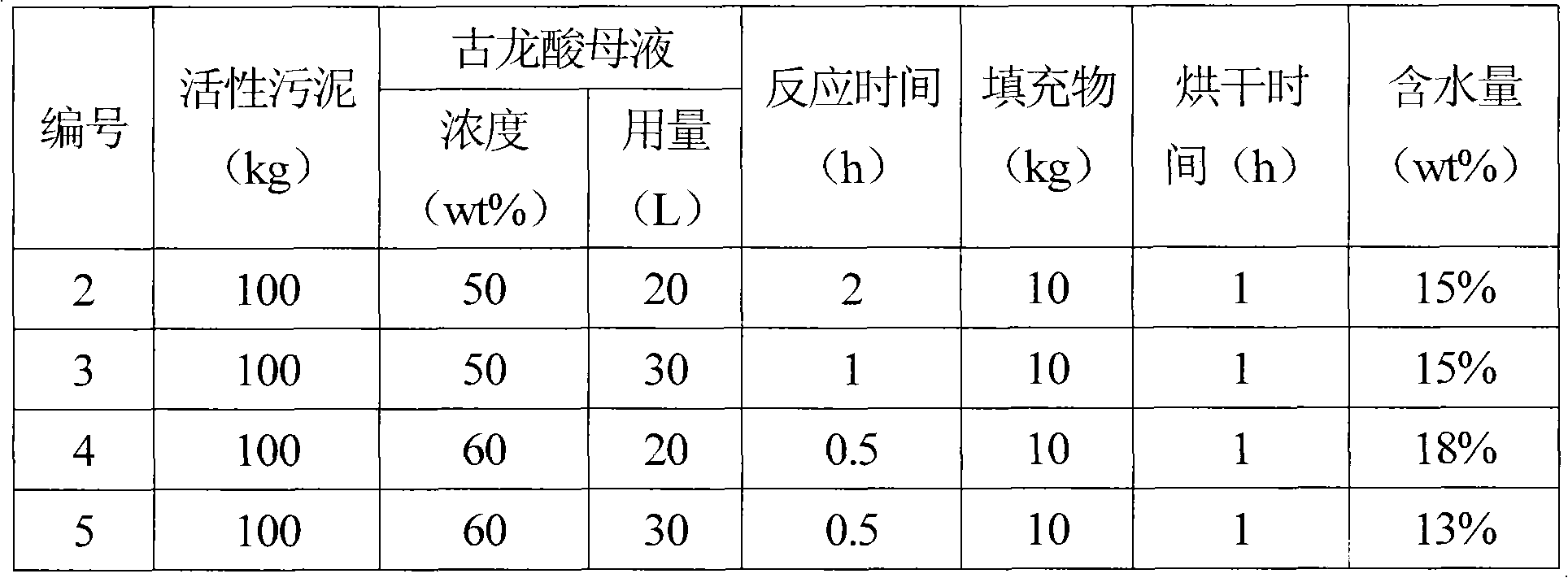

[0019] The concrete process of embodiment 2-5 is the same as embodiment 1, differs from embodiment 1 in that the specific ingredients are shown in table 1.

[0020] Table 1. Ingredients in Examples 2-5

[0021]

Embodiment 6

[0023] Collect 100kg of residual activated sludge after mechanical dehydration, put it in a 500L reaction tank, add 40L of waste organic acid mother liquor, stir evenly to make it into a slurry, heat the tank to 60°C, keep it warm for 4 hours, and export the reaction solution to a Water tank, add 20kg sawdust, stir evenly to thick sauce, move into drum dryer 200 ℃ and dry for 4 hours, make dry sludge, the water content of sludge mixture is 15wt%.

[0024] In this embodiment, the discarded organic acid mother liquor is the discarded mother liquor produced in the extraction of oxalic acid, wherein the concentration of oxalic acid is 40 wt%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com