Method for biofloculating microalgae by using glycine

A glycine microalgae and biological flocculation technology, applied in the field of bioengineering, can solve the problems of high polymer molecular weight, high polymer price, low flocculation efficiency, etc., and achieve the effect of promoting continuous growth, less dosage and reducing equipment investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

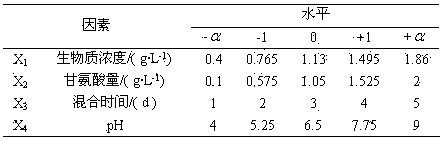

Method used

Image

Examples

Embodiment 1

[0038] A method utilizing glycine microalgae bioflocculation, comprising the following steps:

[0039] 1) Selection of algae species Scenedesmus dimorphus (UTEX 417), before the microalgae is harvested, the biomass concentration DW in the microalgae stock solution is measured 1 is 1.82 g / L, volume V 1 is 100 mL;

[0040] 2) Prepare a glycine concentration of 50 g / L, harvest the volume of microalgae as needed, add 1.0 mL of glycine to the microalgae stock solution, and stir evenly;

[0041]3) Continue culturing the microalgae stock solution with glycine added in step 2) in the culture system for 3 days, cultivate the light of 7500 lux, and the temperature of 25°C to form the first mixed solution, and measure the concentration DW of the microalgae in the first mixed solution 2 is 1.96 g / L, volume V 2 is 100 mL;

[0042] 4) Using hydrochloric acid solution to adjust the pH value of the first mixed solution in step 3) to 5 to form a second mixed solution;

[0043] 5) Put th...

Embodiment 2

[0046] A method utilizing glycine microalgae bioflocculation, comprising the following steps:

[0047] 1) The algae species are botrytis Botryococcus braunii (FACHB-357), before the microalgae is harvested, the biomass concentration DW in the microalgae stock solution is measured 1 is 4.01 g / L, volume V 1 is 100 mL;

[0048] 2) Prepare a glycine concentration of 50 g / L, harvest the volume of microalgae as needed, add 2 mL of glycine to the microalgae stock solution, and stir evenly;

[0049] 3) Continue culturing the microalgae stock solution with glycine added in step 2) in the culture system for 1 day to form the first mixed solution, and measure the concentration DW of the microalgae in the first mixed solution 2 is 4.13 g / L, volume V 2 is 100 mL;

[0050] 4) Using NaOH solution to adjust the pH value of the first mixed solution in step 3) to 9 to form the second mixed solution;

[0051] 5) Put the second mixed solution in step 4) into a glass liquid separator, let ...

Embodiment 3

[0054] A method utilizing glycine microalgae bioflocculation, comprising the following steps:

[0055] 1) Chlorella is selected as the algae species Chlorella sp.2, before harvesting the microalgae, measure the biomass concentration DW in the microalgae stock solution 1 is 3.86 g / L, volume V 1 is 100 mL;

[0056] 2) Prepare a glycine concentration of 50 g / L, harvest the volume of microalgae as needed, add 4 mL of glycine to the microalgae stock solution, and stir evenly;

[0057] 3) Continue culturing the microalgae stock solution with glycine added in step 2) in the culture system for 1 day to form the first mixed solution, and measure the concentration DW of the microalgae in the first mixed solution 2 is 3.90 g / L, volume V 2 is 100 mL;

[0058] 4) Using hydrochloric acid solution to adjust the pH value of the first mixed solution in step 3) to 6.5 to form a second mixed solution;

[0059] 5) Put the second mixed solution in step 4) into a glass separator, let it stan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

| dehydration rate | aaaaa | aaaaa |

| dehydration rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com