Ore pulp thickener

A technology for thickeners and ore pulp, applied in the field of thickeners, can solve the problems of inconvenient use and maintenance, large floor area, easy to press rakes, etc., and achieve the effect of convenient maintenance and good effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

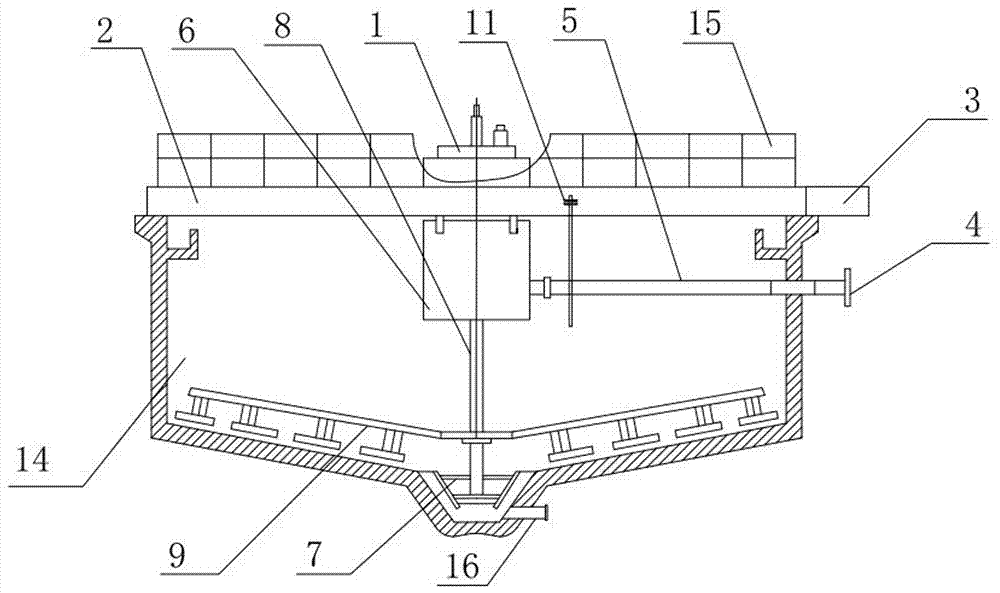

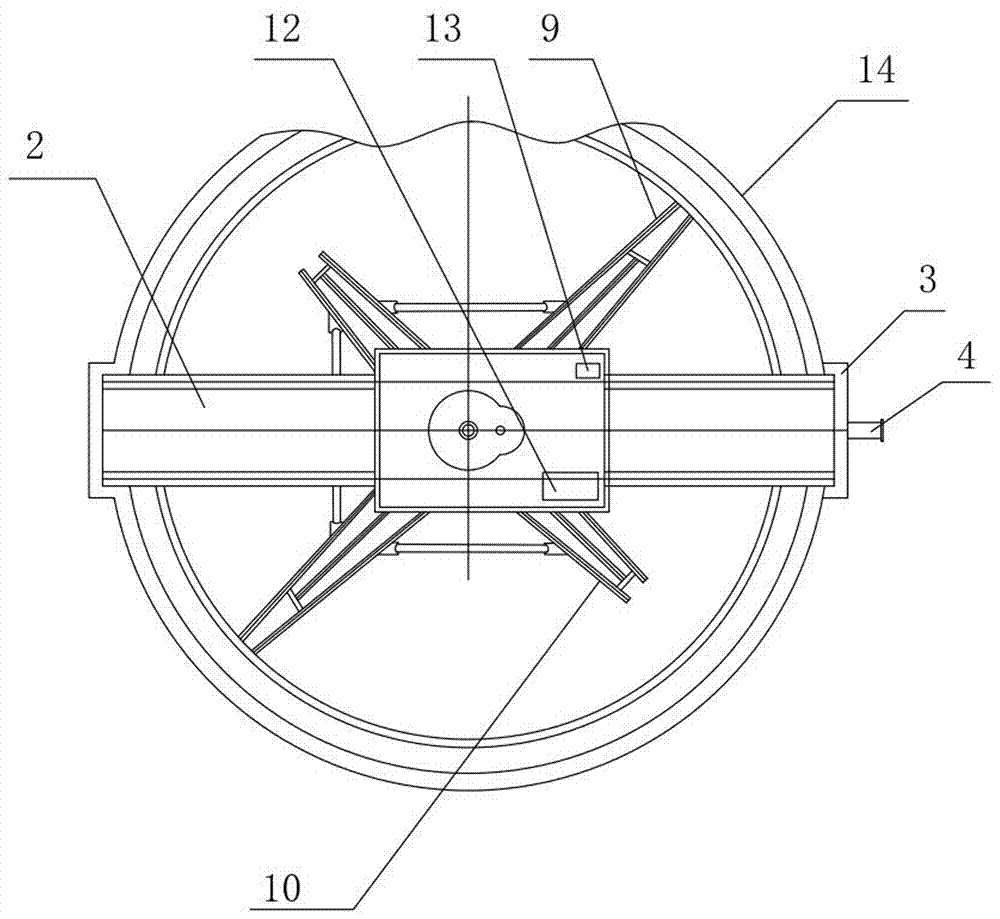

[0015] Such as Figure 1~2 As shown, a pulp thickener includes a thickening tank 14, and also includes a transmission device 1, a bridge frame 2, a ladder 3, a feed port 4, a feed pipe 5, a fixed cylinder 6, a scraper 7, a shaft 8, and a drive shaft rake , boom 11, hydraulic station 12, electric control device 13, conveying pipe 16, the bridge frame 2 is arranged on the top of the concentration pool 14, the transmission device 1 is arranged on the bridge frame 2, the ladder 3 is connected with the bridge frame 2, and the The feed port 4 is arranged on one side of the concentration tank 14, the feed pipe 5 is arranged in the concentration tank 14, and the two ends of the feed pipe 5 are respectively connected with the feed port 4 and the fixed cylinder 6, and the fixed cylinder 6 is set Below the bridge frame 2, the shaft 8 is set in the concentration tank 14 and connected to the transmission device 1, the scraper 7 is set at the center of the bottom of the concentration tank 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com