Dehydration conditioner for high temperature anaerobic digested sludge and dehydration method of high temperature anaerobic digested sludge

A high-temperature anaerobic sludge digestion technology, applied in water/sludge/sewage treatment, sludge treatment, chemical instruments and methods, etc., can solve the problems of poor biochemical properties, increased sludge ash content, corrosion of treatment equipment, etc. problems, achieve the effects of reducing mutual repulsion, accelerating sludge settling, and improving dewatering performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

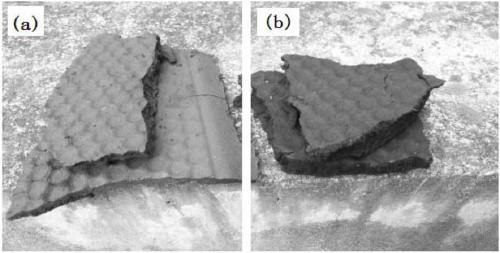

Image

Examples

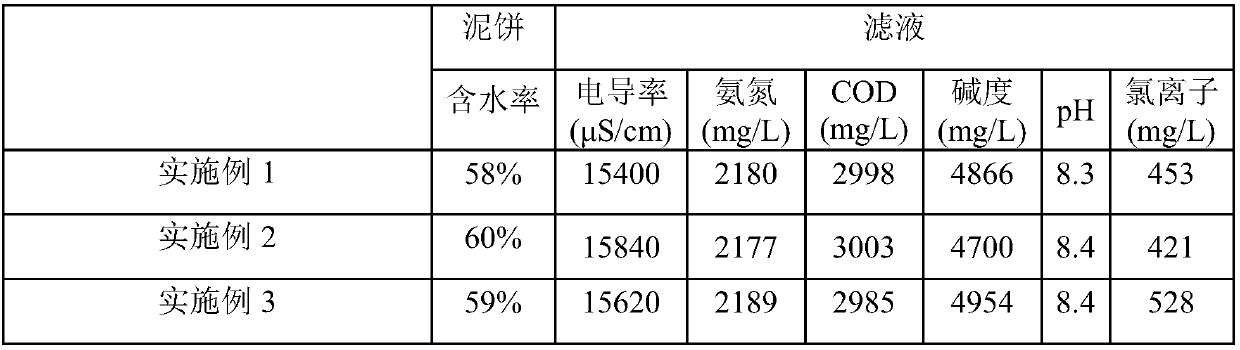

Embodiment 1

[0033] A dehydration conditioner for high-temperature anaerobic digestion of sludge, the dehydration conditioner comprises acryloyloxyethyl trimethyl copolymer and cationic polyacrylamide, wherein the weight ratio of acryloyloxyethyl trimethyl copolymer The solid content of the high-temperature anaerobic digestion sludge is 1.37%, and the weight ratio of the cationic polyacrylamide is 0.27% of the high-temperature anaerobic digestion sludge solid content.

[0034] In this embodiment, the molecular weight of the acryloyloxyethyl trimethyl copolymer is 1 million.

[0035] In this embodiment, the cationic polyacrylamide is in powder form, with an ionization degree of 60% and a molecular weight of 8 million.

[0036] A method for dehydrating high-temperature anaerobic digested sludge, comprising the following steps:

[0037] (1) The acryloyloxyethyl trimethyl copolymer is mixed with water to obtain an acryloyloxyethyl trimethyl copolymer solution with a mass concentration of 10%....

Embodiment 2

[0043] A dehydration conditioner for high-temperature anaerobic digestion of sludge, the dehydration conditioner comprises acryloyloxyethyl trimethyl copolymer and cationic polyacrylamide, wherein the weight ratio of acryloyloxyethyl trimethyl copolymer The solid content of the high-temperature anaerobic digestion sludge is 1.1%, and the weight ratio of the cationic polyacrylamide is 0.36% of the high-temperature anaerobic digestion sludge solid content.

[0044] In this embodiment, the molecular weight of the acryloyloxyethyl trimethyl copolymer is 1 million.

[0045] In this embodiment, the cationic polyacrylamide is in powder form, with an ionization degree of 60% and a molecular weight of 8 million.

[0046] A method for dehydrating high-temperature anaerobic digested sludge, comprising the following steps:

[0047] (1) The acryloyloxyethyl trimethyl copolymer is mixed with water to obtain an acryloyloxyethyl trimethyl copolymer solution with a mass concentration of 10%. ...

Embodiment 3

[0053] A dehydration conditioner for high-temperature anaerobic digestion of sludge, the dehydration conditioner comprises acryloyloxyethyl trimethyl copolymer and cationic polyacrylamide, wherein the weight ratio of acryloyloxyethyl trimethyl copolymer The solid content of the high-temperature anaerobic digestion sludge is 1.1%, and the weight ratio of the cationic polyacrylamide is 0.36% of the high-temperature anaerobic digestion sludge solid content.

[0054] In this embodiment, the molecular weight of the acryloyloxyethyl trimethyl copolymer is 1 million.

[0055] In this embodiment, the cationic polyacrylamide is in powder form, with an ionization degree of 60% and a molecular weight of 8 million.

[0056] A method for dehydrating high-temperature anaerobic digested sludge, comprising the following steps:

[0057] (1) dissolving acryloyloxyethyl trimethyl copolymer and cationic polyacrylamide in water to obtain a mixed solution, the mass concentration of acryloyloxyethy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| ionicity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com