High pressure water-saving jet dyeing technology for wool fabrics and vaporized water recovery system

A jet dyeing and fabric technology, applied in the field of wool fabric high-pressure water-saving jet dyeing technology and vaporized water recovery system, can solve the problems of poor dyeing uniformity, waste of water resources, slow speed, etc., and achieve dyeing uniformity Improve and avoid the waste of water resources and improve the effect of firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

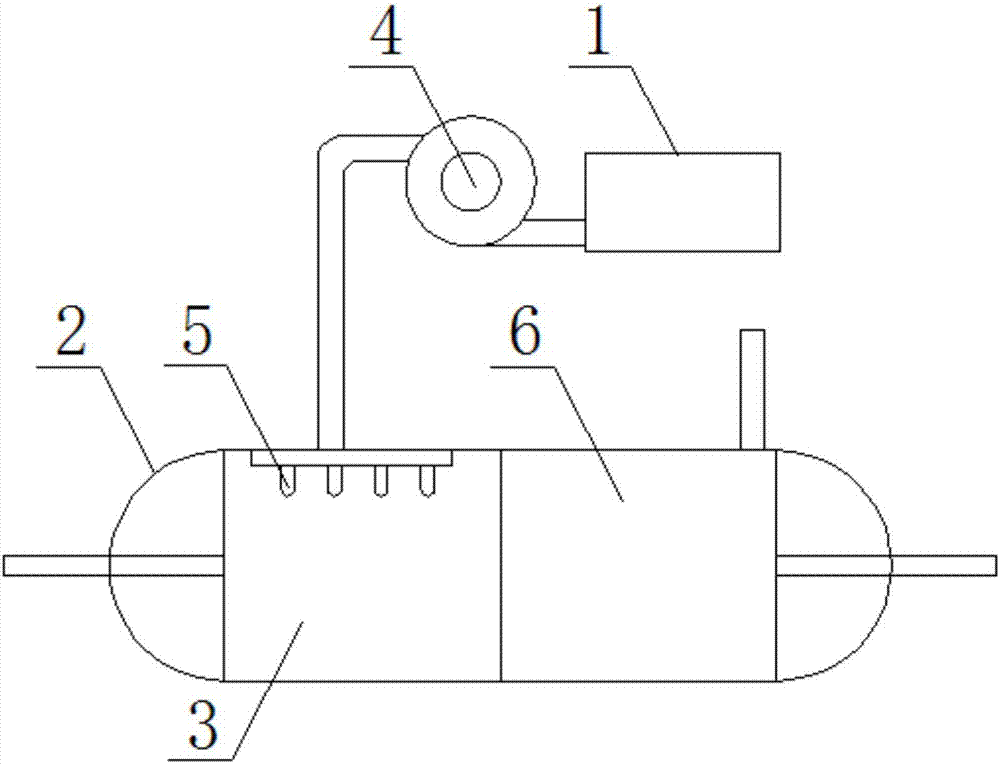

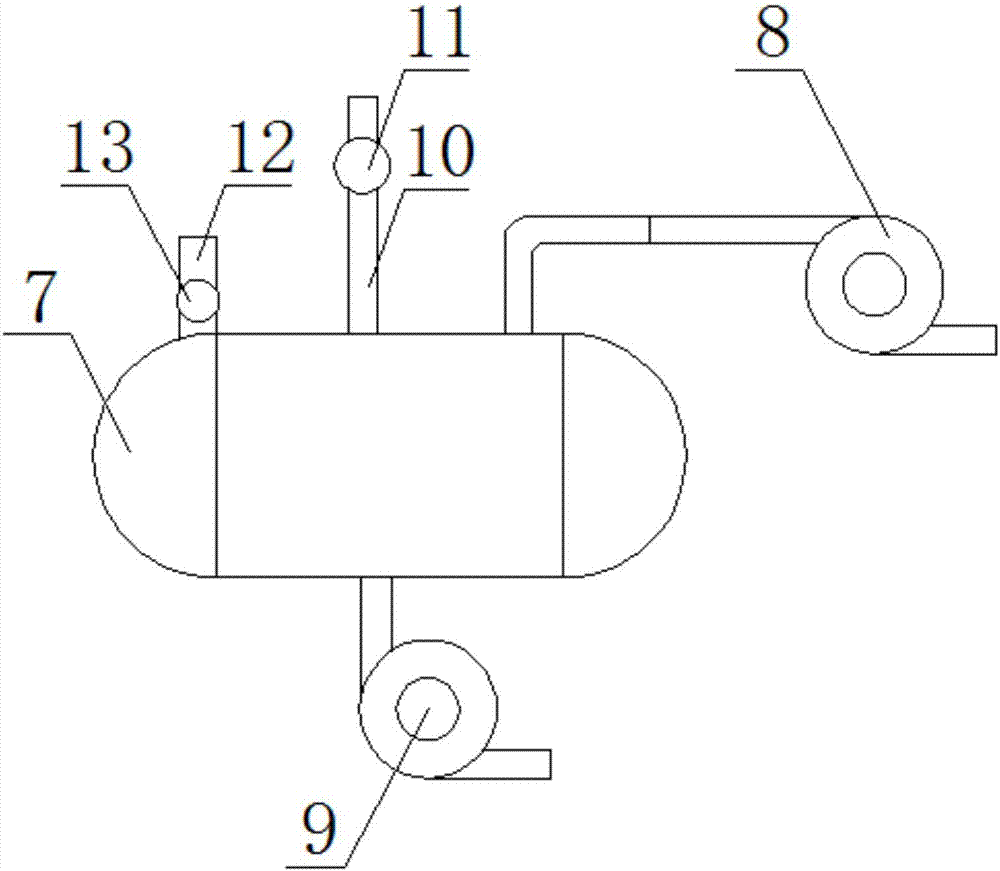

[0038] The invention discloses a wool fabric high-pressure water-saving jet dyeing technology and vaporized water recovery system. The specific steps are as follows:

[0039] Step 1, adding dye and water into the dye vat for mixing;

[0040] Step 2: Heating the dyeing solution to 40°C at a rate of 2°C / min, while adjusting the pressure in the high-pressure cavity of the dyeing shell to 22MPa, and adjusting the temperature in the high-pressure cavity to 40°C;

[0041] Step 3: Transport the wool fabric into the high-pressure chamber, use a centrifugal pump to suck the dye in the dye tank, and then the centrifugal pump transports the dye to the nozzle in the high-pressure chamber, and the nozzle will uniformly jet-dye the wool fabric;

[0042] Step 4. Transport the jet-dyed wool fabric to the low-pressure chamber of the dyeing shell. The pressure in the low-pressure chamber is 0.13MPa and the temperature is 20°C. The water attached to the surface of the wool fabric is vaporized, a...

Embodiment 2

[0048] The invention discloses a wool fabric high-pressure water-saving jet dyeing technology and vaporized water recovery system. The specific steps are as follows:

[0049] Step 1, adding dye and water into the dye vat for mixing;

[0050] Step 2: Heating the dyeing liquor to 55°C at a rate of 2°C / min, while adjusting the pressure in the high-pressure cavity of the dyeing shell to 24MPa, and the temperature in the high-pressure cavity to 55°C;

[0051] Step 3: Transport the wool fabric into the high-pressure chamber, use a centrifugal pump to suck the dye in the dye tank, and then the centrifugal pump transports the dye to the nozzle in the high-pressure chamber, and the nozzle will uniformly jet-dye the wool fabric;

[0052] Step 4. Transport the jet-dyed wool fabric to the low-pressure chamber of the dyeing shell. The pressure in the low-pressure chamber is 0.16MPa and the temperature is 40°C. The water attached to the surface of the wool fabric is vaporized, and the wool ...

Embodiment 3

[0058] The invention discloses a wool fabric high-pressure water-saving jet dyeing technology and vaporized water recovery system. The specific steps are as follows:

[0059] Step 1, adding dye and water into the dye vat for mixing;

[0060] Step 2: Heating the dye solution to 42°C at a rate of 2°C / min, while adjusting the pressure in the high-pressure chamber of the dyeing shell to 23MPa and the temperature in the high-pressure chamber to 43°C;

[0061] Step 3: Transport the wool fabric into the high-pressure chamber, use a centrifugal pump to suck the dye in the dye tank, and then the centrifugal pump transports the dye to the nozzle in the high-pressure chamber, and the nozzle will uniformly jet-dye the wool fabric;

[0062] Step 4. Transport the jet-dyed wool fabric to the low-pressure chamber of the dyeing shell. The pressure in the low-pressure chamber is 0.14MPa and the temperature is 28°C. The water attached to the surface of the wool fabric is vaporized, and the wool ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com