Sludge dewatering additive

A sludge dehydration and additive technology, which is applied in dehydration/drying/concentrated sludge treatment, cement production, climate change adaptation, etc., can solve problems such as human health hazards, excessive heavy metal content in food and vegetables, and large investment

Inactive Publication Date: 2011-06-29

郑建国

View PDF3 Cites 15 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At present, several better sludge treatment methods are: ① Fry the sludge to remove the water, and use the solid matter as a raw material for fuel; the disadvantage of this method is: invest in a sludge treatment production line, It needs more than 80 million yuan, and the operating cost is extremely high. Based on the 10-year life of the equipment in the process, it costs 500,000 yuan to process one ton of sludge, and the operating cost is about 180 yuan; ②Many countries use power stones to generate tail gas Dry the sludge and use solid matter as raw material for fuel. The disadvantages of this method are: large investment and high operating cost. It takes 100,000-120,000 yuan to process one ton of sludge, and the operating cost is about 200 yuan; ③The sludge is fermented and made into fertilizer. Its shortcoming is that heavy metals such as mercury and zinc in the sludge are easily absorbed through plant roots, making the heavy metal content of grain and vegetables exceed the standard, which is harmful to human health

Method used

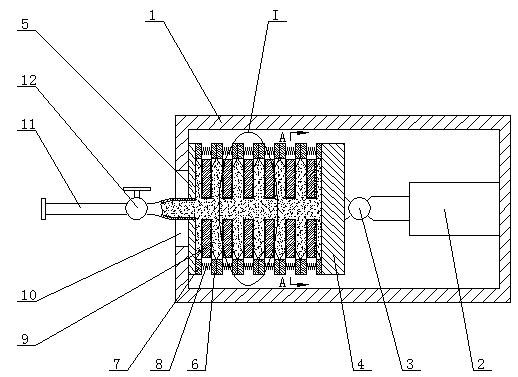

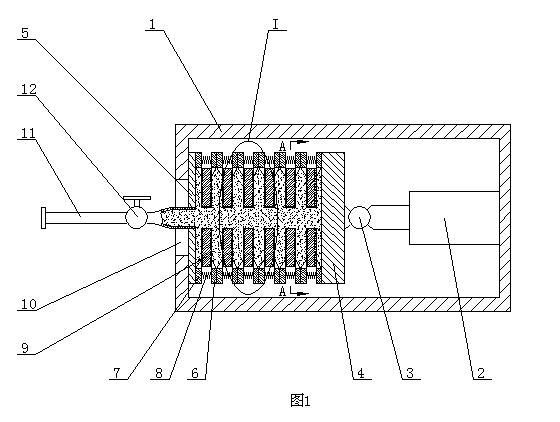

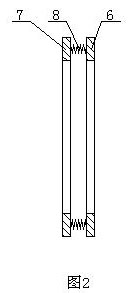

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| water content | aaaaa | aaaaa |

Login to View More

Abstract

The invention discloses a sludge dewatering additive. The sludge dewatering additive comprises raw materials with the weight ratios as follows: 20 to 70 parts of magnesium chloride, 30 to 80 parts of modified dolomite, 0 to 5 parts of calcium chloride, and 8 to 10 parts of heavy calcium carbonate. The sludge dewatering additive disclosed by the invention destroys cell water in sludge, so that after a large number of moisture contained in the cell water of the sludge is lost and the sludge is filter-pressed and then placed in a natural environment, the moisture in the cell water of the sludge can continuously evaporates; and after the sludge is naturally desiccated for 36 hours, the water content in the sludge can be reduced to around 10 percent, thereby providing a very good basis for reutilization of the sludge. Meanwhile, by using the sludge dewatering additive disclosed by the invention, heavy metal in the sludge can be solidified in the sludge, cannot be absorbed by plant roots, and cannot be diffused into soil and water. Therefore, the sludge dewatered by using the sludge dewatering additive disclosed by the invention cannot cause secondary pollution, and when the dewatered sludge is used as raw material of fertilizer, fuel or building material, secondary pollution cannot be caused.

Description

A kind of sludge dehydration additive technical field The invention relates to sludge treatment and is a sludge dehydration additive. Background technique The sludge produced after the treatment of domestic water and industrial wastewater contains extremely complex heterogeneous bodies such as organic debris, bacterial cells, inorganic particles, colloids, etc. Since the water content of the sludge is as high as 85%, it is very easy to rot and become smelly , and its transportation and storage seriously pollute the environment. Since the dehydration of sludge is an extremely difficult technology, countries all over the world initially used the landfill method for sludge treatment. However, with the advancement of technology, it was found that the landfill of sludge did not eliminate pollution and caused serious damage to water. Resources and crops have serious harm. After entering the 1980s, the treatment of sludge has been greatly improved. At present, several better s...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C02F11/14

CPCY02E50/30Y02E50/10Y02A40/20Y02P40/10

Inventor 郑建国

Owner 郑建国

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com