Sand and water separation system and method

A sand-water separation and dewatering screen technology, which is applied in separation methods, filtration separation, chemical instruments and methods, etc., can solve problems such as waste, high power consumption, and large floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

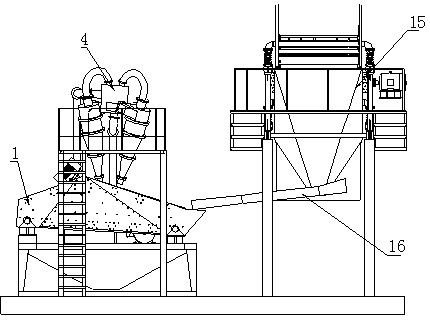

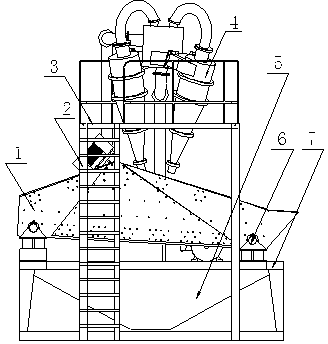

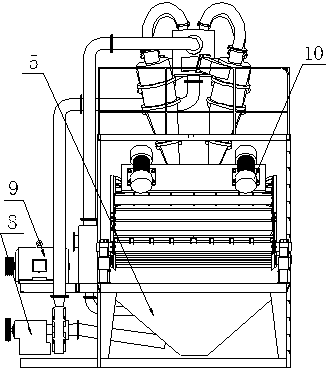

[0015] Embodiment 1: with reference to attached Figure 1-6 . A sand-water separation system, including a dewatering screen, a cyclone (one set) or a cyclone group and vibration screening equipment, the vibration screening equipment 15 and the wide water storage type dehydration screen 1 are integrated on the base, and the cyclone Or the cyclone group 4 is integrated on the top of the wide water storage dewatering screen 1 through the support frame, and the sand-water mixture is conveyed between the vibration screening equipment 15 and the wide water storage dewatering screen 1 through the quicksand tank 16, and the wide water storage type The dewatering screen 1 is positioned on the frame 7 through the shock absorber 6, and the shock absorber 6 is a rubber-metal helical composite spring, or a hydraulic shock absorber. When the rubber-metal helical composite spring is used as the shock absorber, the lower port of the rubber-metal helical composite spring is plugged with the b...

Embodiment 2

[0020] Embodiment 2: On the basis of Embodiment 1, when the flow rate of sand water treated by the wide-width water storage dewatering screen 1 per hour is greater than 300 cubic meters of water, the bottom plate, lower end sieve plate and side sieve plates of the frame are all screen holes plate.

Embodiment 3

[0021] Embodiment 3: On the basis of Embodiment 1, a sand-water separation method of a sand-water separation system, the sediment-water mixture screened by the vibrating screening device 15 passes through the quicksand tank 16 to the wide water storage type dewatering screen 1, Since the inclination angle between the bottom plate of the wide water storage dewatering screen 15 and the horizontal plane is greater than 3 degrees, and the vibration of the wide water storage dewatering screen 1 is driven by an exciting motor or a camshaft drive mechanism, the wide water storage dewatering screen is forced to The vibration trajectory of the screen 1 forms a front-to-back straight-line walking up and down motion, so when the sand-water mixture washed down from the vibrating screening equipment 15 is washed through the wide-width water storage dewatering screen 15 to the outwardly inclined open facade screen hole When the plate 13 is on the surface, the outwardly inclined open facade s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com