Spiral driving device and mop using same

A screw drive and mop technology, applied in the field of mops, can solve the problems of one-way bearing losing transmission function, stuck and wearing one-way bearing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

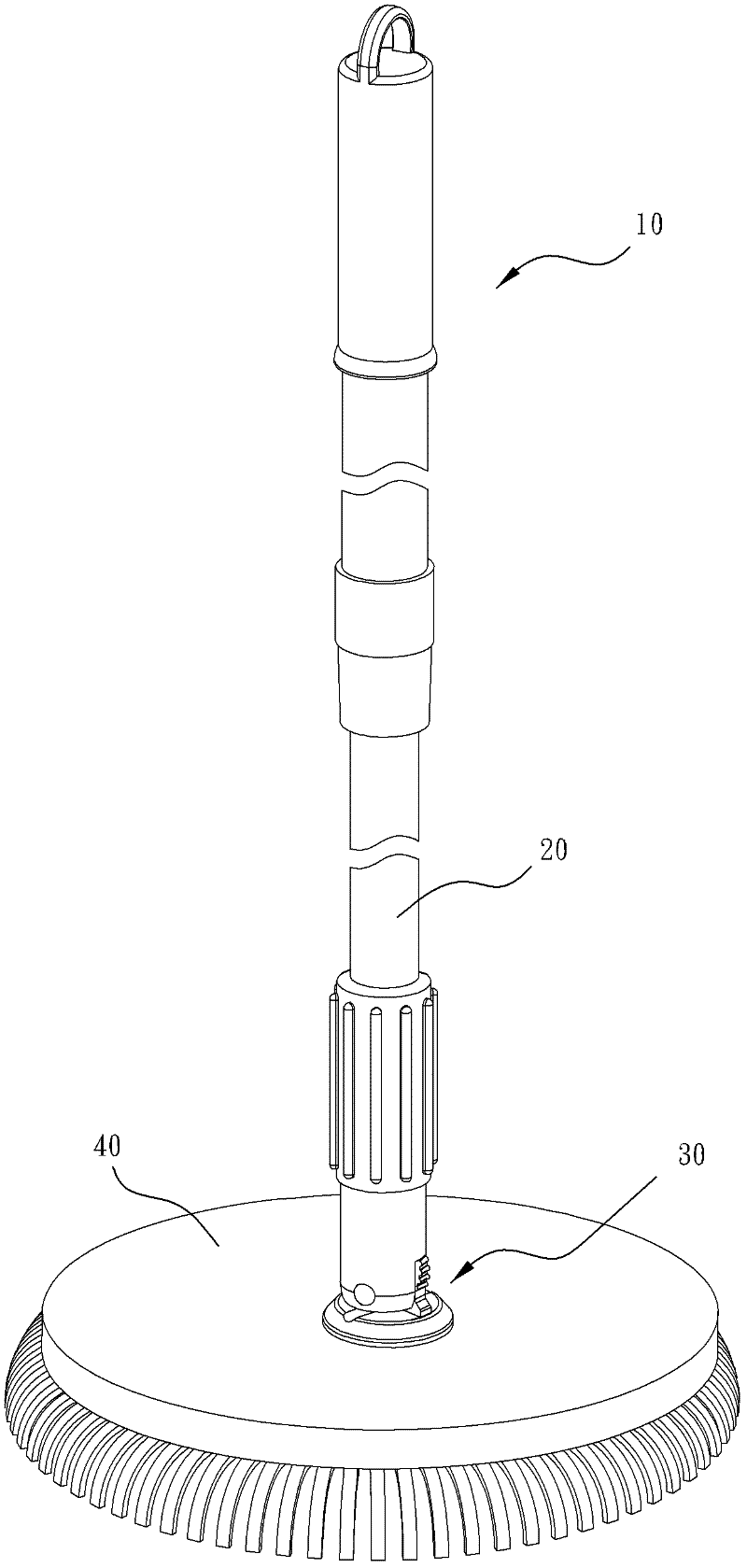

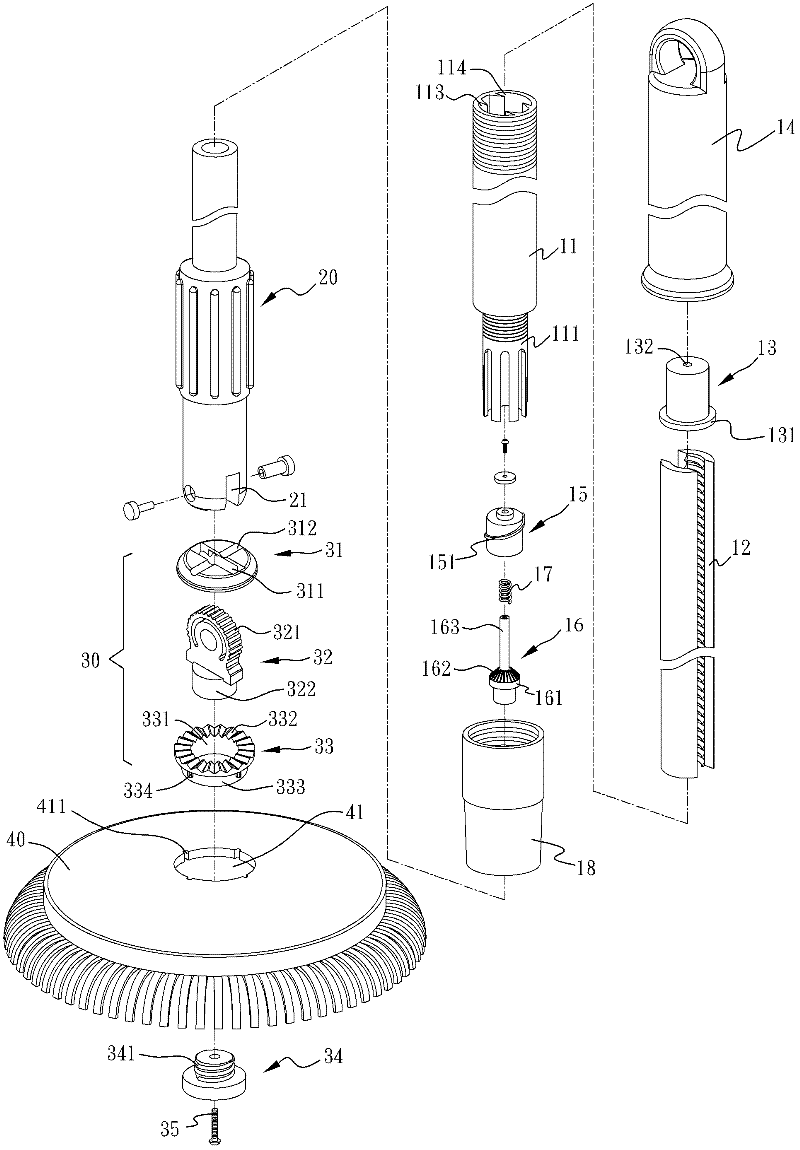

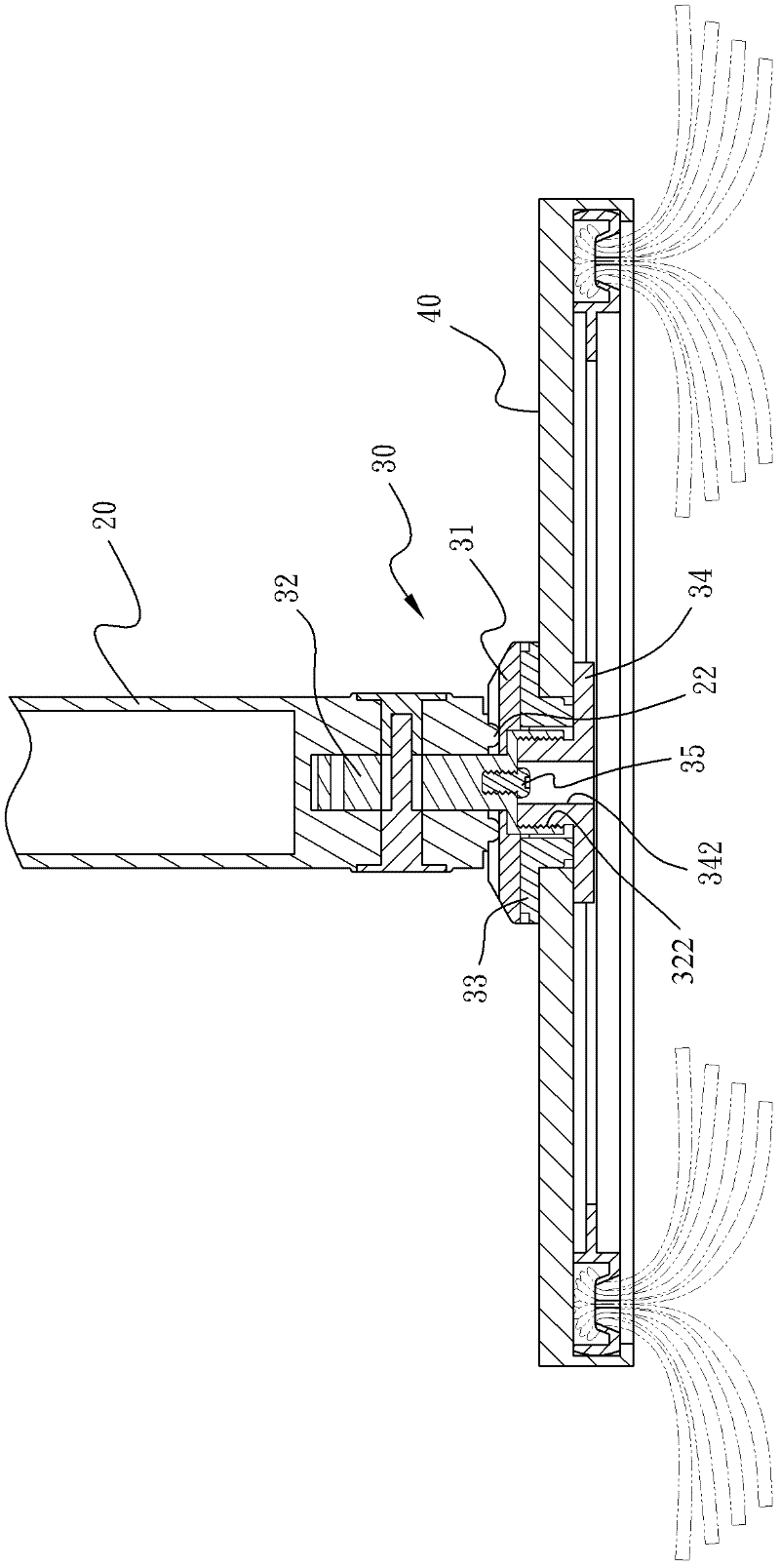

[0062] refer to Figure 1 to Figure 4 , in the first embodiment of the mop of the present invention, it mainly includes a columnar screw driving device 10, a connecting rod 20 that is coaxially connected to the screw driving device 10 and driven by it, and a connecting device 30 that is installed The mop head 40 at the free end of the connecting rod 20 .

[0063] The screw driving device 10 includes an outer tube 11 . A bundle of tubes 111 extends coaxially from the bottom end of the outer tube 11 , and a ring-shaped shoulder 112 is formed at the junction of the bundle tube 111 and the outer tube 11 . Two pairs of convex ribs 113 are longitudinally formed on the inner wall of the outer tube 11, and a dovetail groove 114 is formed between each pair of convex ribs 113. There is a threaded tooth plate 12 , and the threads on the two tooth plates 12 form a continuous spiral correspondence, and are limited by the annular shoulder 112 . A sleeve 14 is coaxially locked on the top o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com