Washing machine and washing method

A washing method and washing machine technology, which are applied to other washing machines, control devices of washing machines, washing devices, etc., can solve the problems of complicated washing machine structure and washing process, and achieve the effect of simplifying the process of separation and recovery, and simplifying the washing process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

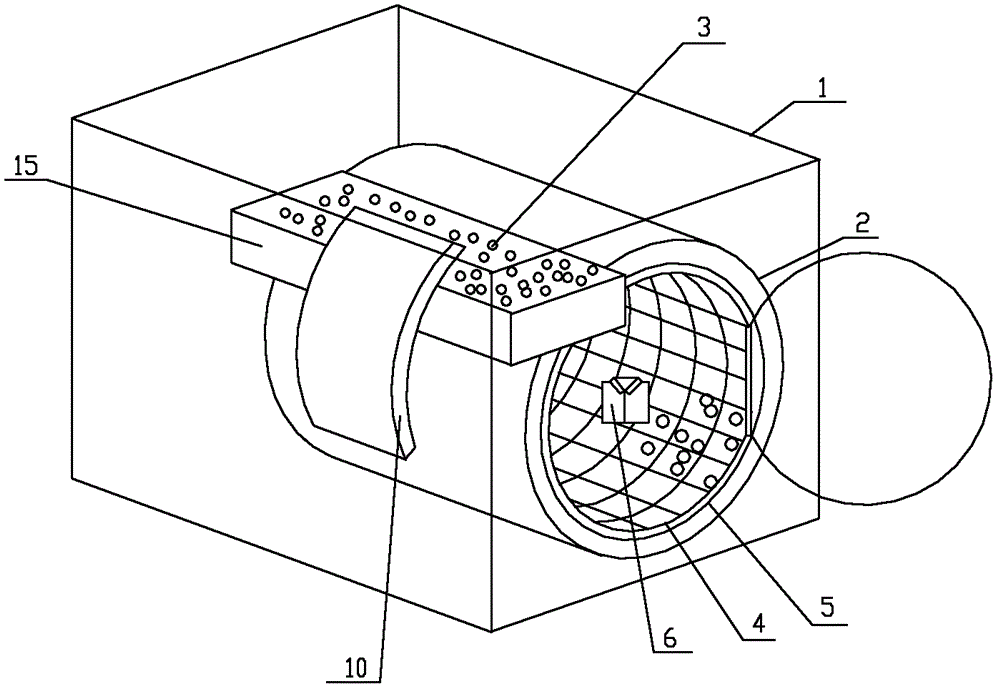

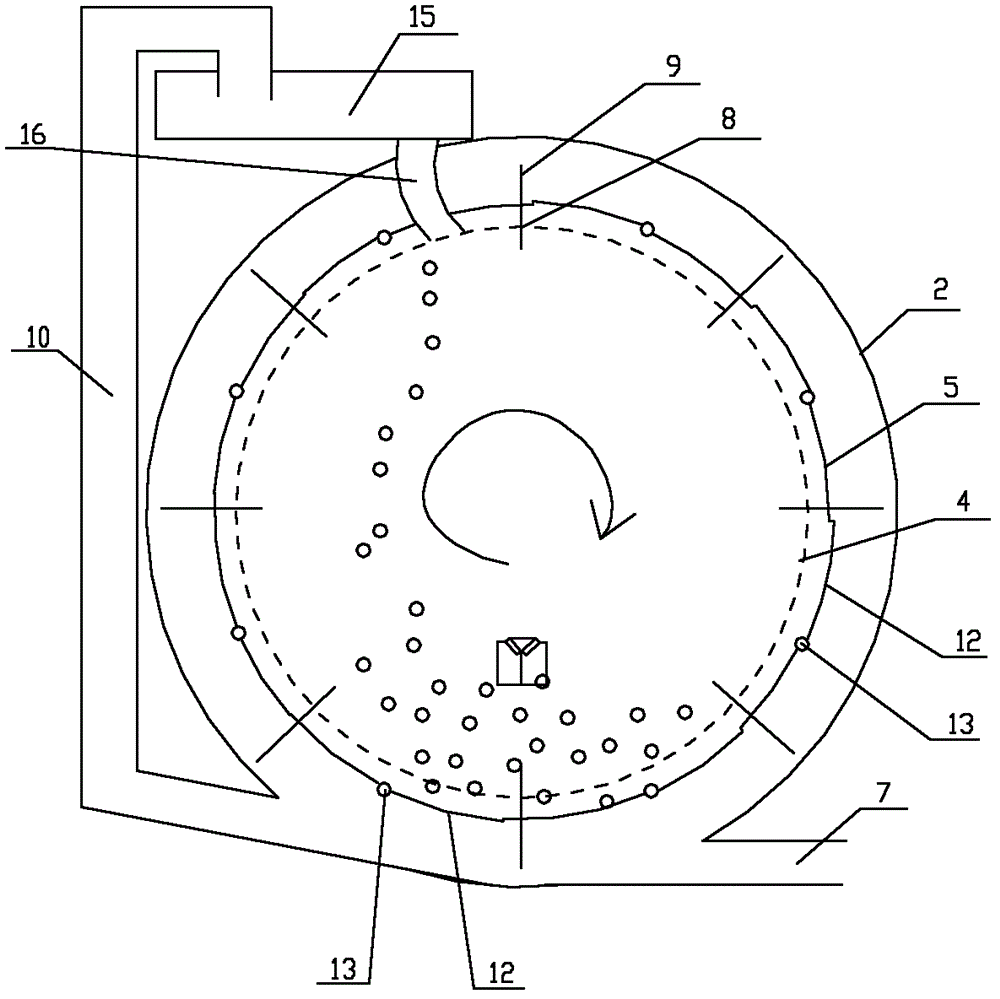

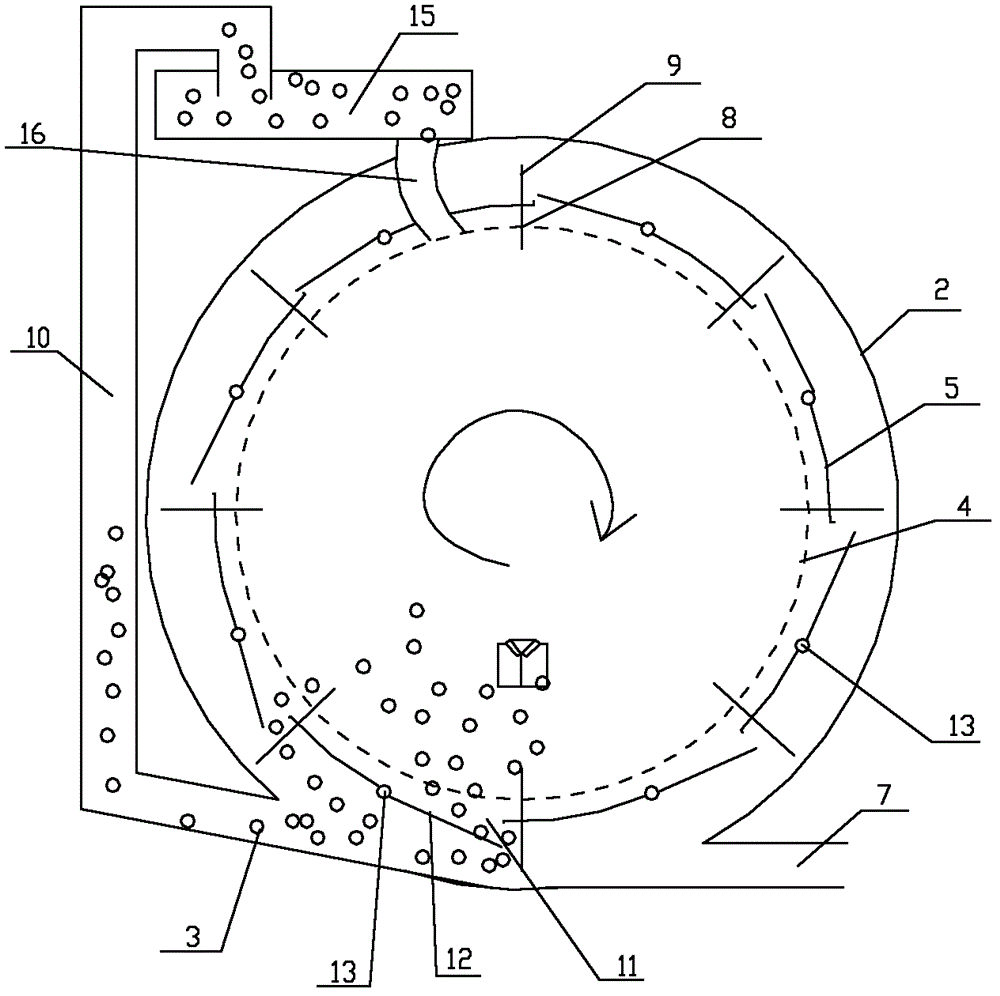

[0036] Such as figure 1 As shown, this embodiment takes a drum washing machine as an example for detailed description. The washing machine includes a housing 1, and an outer cylinder 2, an inner cylinder and solid particles 3 as a washing medium are arranged in the housing 1. Wherein, the outer cylinder 2 is fixed and does not rotate, and is mainly used for holding water. A water inlet (not shown in the figure) is arranged on the upper part of the outer cylinder 2 for the water inlet of the washing and rinsing process. Drain outlet 7 is arranged, is used for the drainage after dehydration. The particle 3 is preferably made of polymer surface porous material, which can improve the adsorption capacity and achieve better washing effect.

[0037] The inner cylinder is arranged on the inner side of the outer cylinder 2, and the inner cylinder is us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com