A kind of washing machine and washing method

A washing machine and inner tub technology, applied in the field of washing machines and washing methods, and washing machines, can solve the problems of complicated washing machine structure and washing process, and achieve the effects of simplifying the separation and recovery process, reducing noise, and simplifying the washing process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

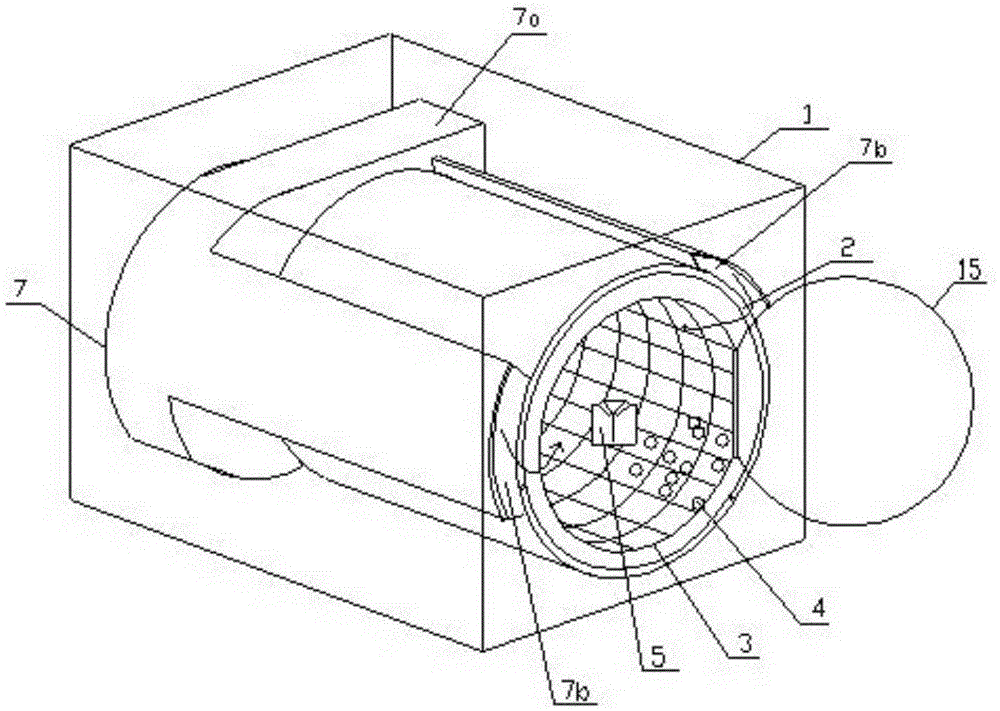

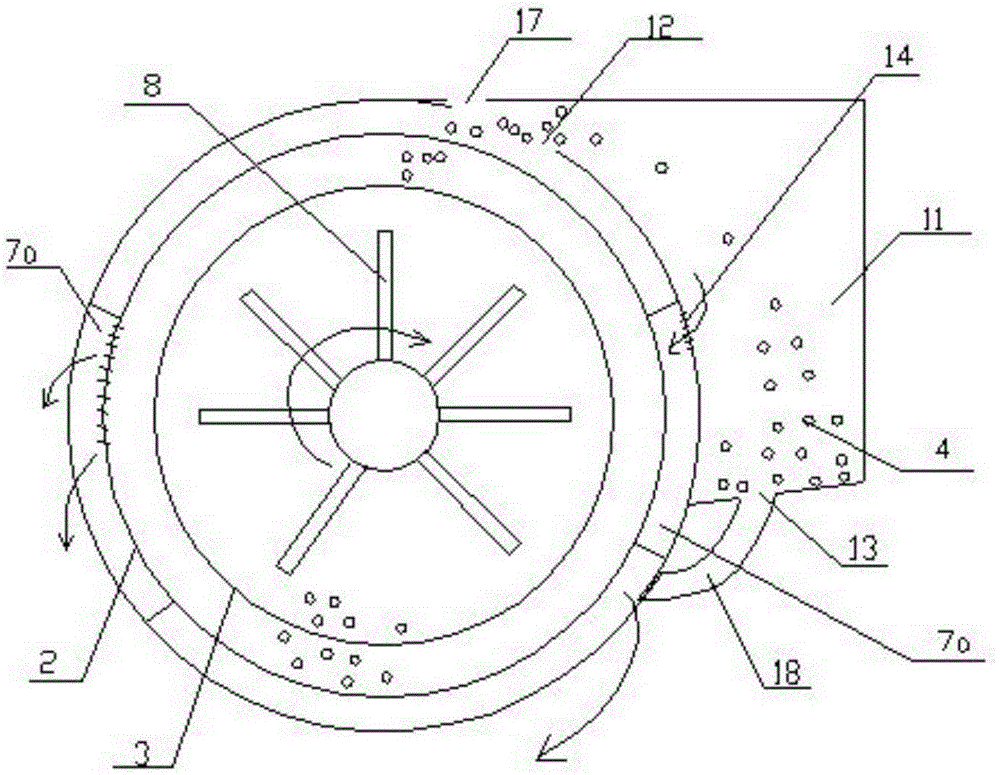

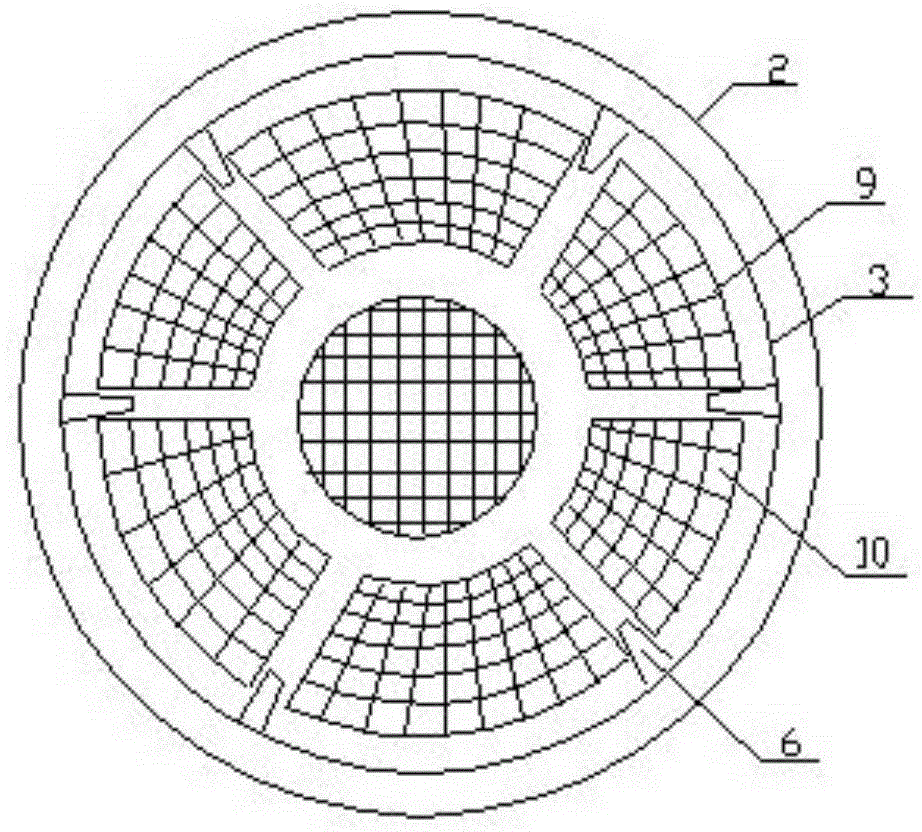

[0033] Such as figure 1 As shown, this embodiment takes a drum washing machine as an example for detailed description. The washing machine includes a housing 1, and an outer cylinder 2, an inner cylinder 3 and solid particles 4 as a washing medium are arranged in the housing 1, wherein the outer cylinder 2 It is fixed and non-rotating, and is mainly used for holding water. The inner cylinder 3 is arranged on the inner side of the outer cylinder 2. The inner cylinder 3 is used for washing. The inner cylinder 3 is driven to rotate by a driving device (not shown in the figure), and the laundry 5 is placed In the inner cylinder 3, a water inlet (not shown) is provided on the upper part of the outer cylinder 2 for water intake in the washing and rinsing process, and a water outlet (not shown) is provided at the bottom of the outer cylinder 2, Used for drainage after dehydration. The particle 4 is preferably made of polymer surface porous material, which can improve the adsorption ...

Embodiment 2

[0057] The difference from Embodiment 1 is that the air inlet section 7b of the air duct 7 is fixed on the outer wall of the outer cylinder 2 in a ring shape, and surrounds the outer cylinder 2 therein. An annular air inlet can be set at the air inlet of the air inlet section 7b, or several air inlets can be arranged intermittently, and a filter screen 14 for preventing particles 4 from entering the air duct 7 is arranged at the air inlet. In this way, the air intake in the inner tube 3 is larger, which is more conducive to the separation and air drying of the particles 4 and the clothes 5 .

Embodiment 3

[0059] The difference from Embodiment 1 is that in this embodiment, the discharge port 13 of the material storage space 11 communicates with the air inlet section 7b in the air duct 7. In order to facilitate the flow of particles 4, the discharge port 13 is arranged in the storage space The bottom position of 11 is provided with an openable and closable door (not marked among the figures) at discharge port 13 places, and the openable and closable door can select electromagnetic valve etc. Before washing, the electromagnetic valve at the discharge port 13 is opened by the control device, and the storage space 11 is communicated with the air inlet section 7b of the air duct 7. The section 7b flows toward the front end of the inner cylinder 3, and the particles 4 entering the air inlet section 7b of the air duct 7 will move forward under the drive of the air flow, and finally enter the inner cylinder 3 to complete the delivery of the particles 4.

[0060] During this delivery pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com