Manufacturing method of electrowetting display assembly

A technology of electrowetting display and manufacturing method, applied in the direction of optical components, optics, instruments, etc., can solve the problems of a large number of hydrophilic substances, and achieve the effect of eliminating necessity and avoiding freezing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

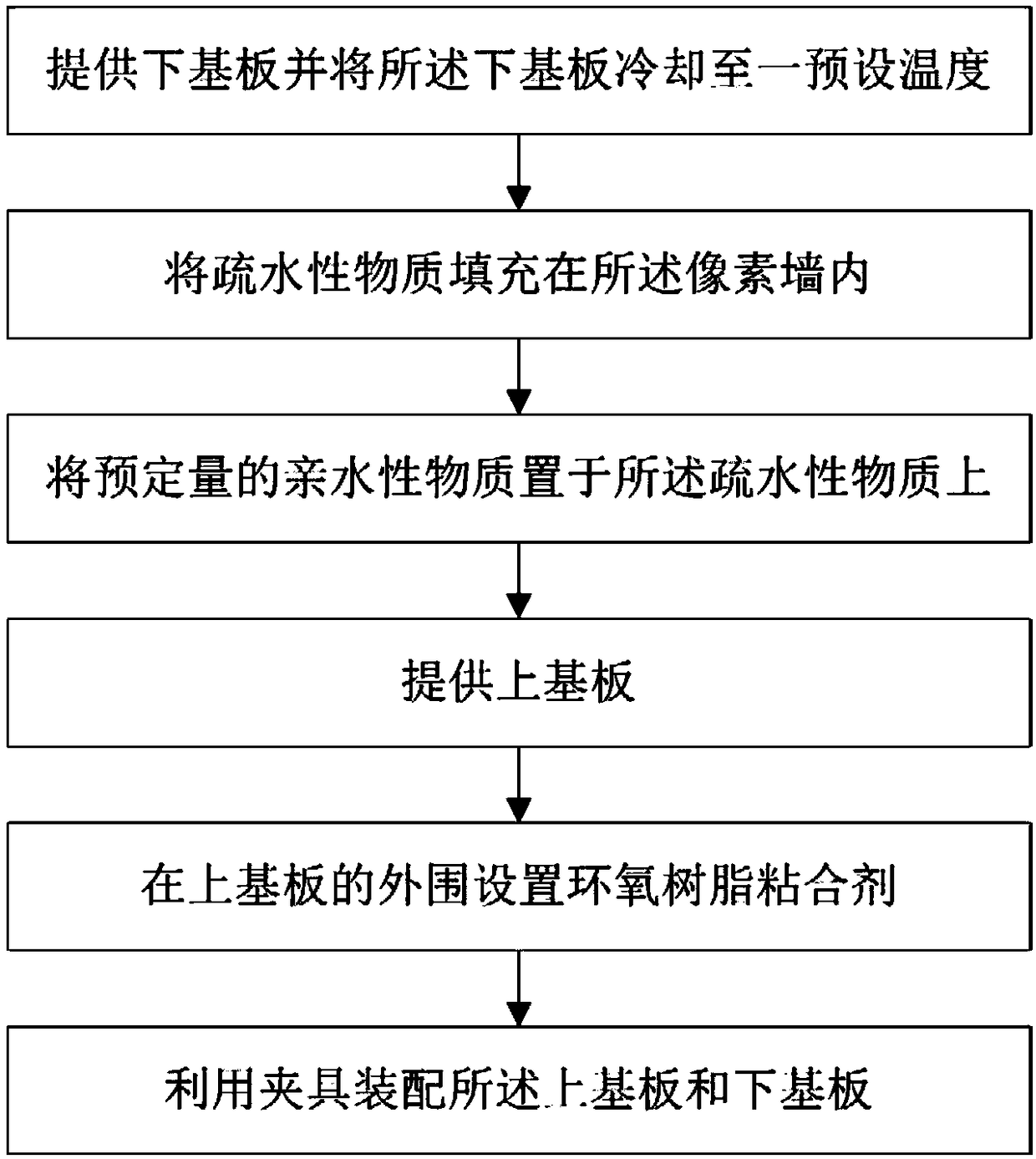

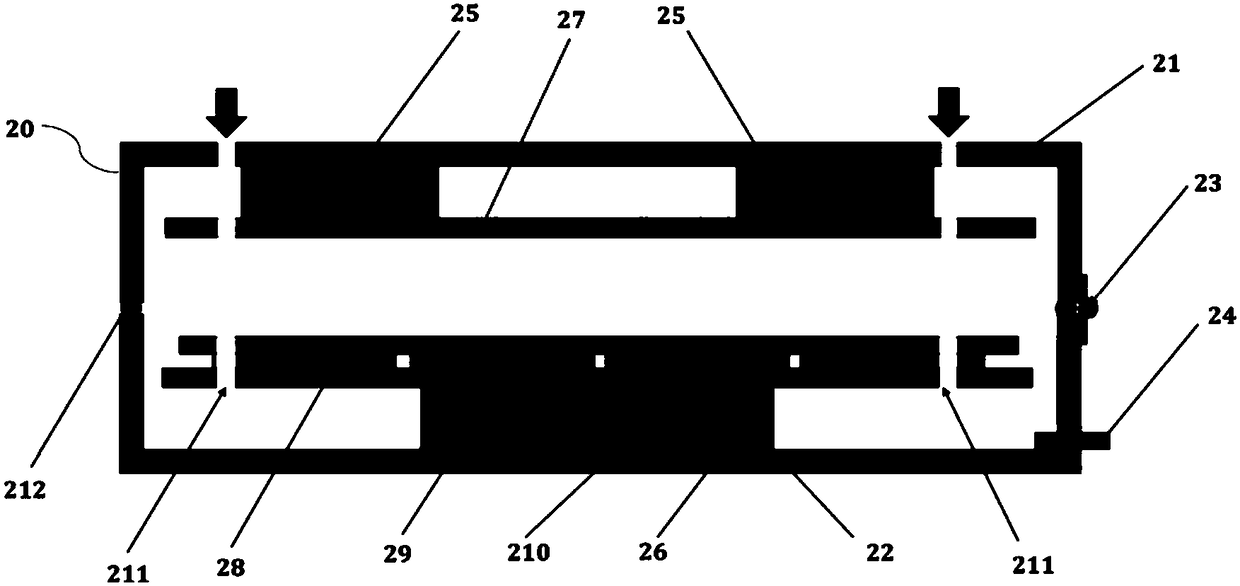

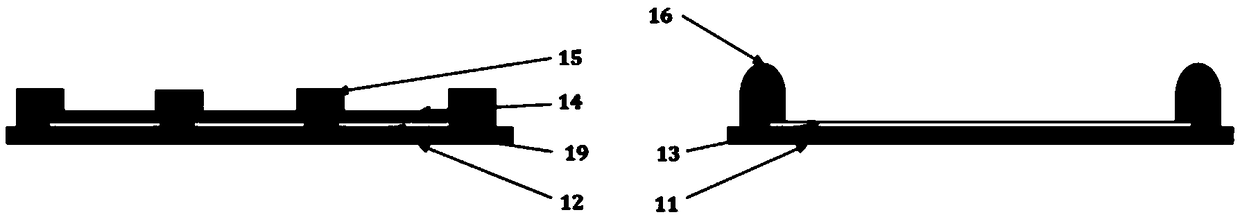

[0035] refer to figure 1 , according to a manufacturing method of an electrowetting display component of the present invention, comprising the following steps: providing a lower substrate and cooling the lower substrate to a preset temperature, wherein the lower substrate is pre-formed with a lower electrode, a hydrophobic dielectric electrical layer and patterned pixel wall; filling the hydrophobic substance in the pixel wall, wherein the freezing point of the hydrophobic substance is higher than the preset temperature so that the hydrophobic substance is solid, so as to completely eliminate The necessity of assembling the electrowetting display assembly under water, and realizing the electrolyte of the electrowetting display assembly other than water; placing a predetermined amount of hydrophilic substance on the hydrophobic substance, the hydrophilic The freezing point of the aqueous substance is lower than or equal to the preset temperature so that the hydrophilic substanc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com