A kind of master alloy for regenerated aluminum and iron-rich phase modification and preparation method thereof

A technology for master alloys and secondary aluminum, applied in the field of new materials and metallurgy, can solve the problems of unsuitable smelting of aluminum and its alloys, increase iron, increase costs, etc. The effect of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

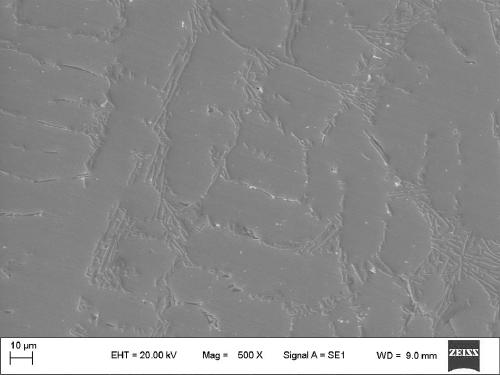

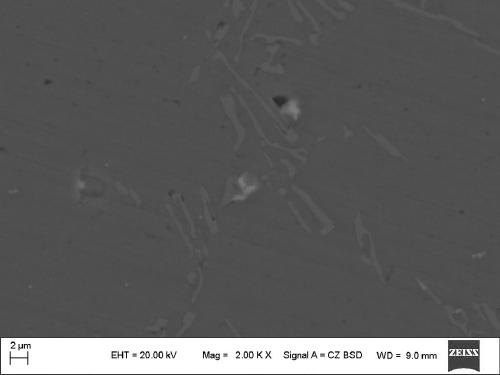

Image

Examples

Embodiment 1

[0031] Weigh 99g Al-Mn master alloy, 1g WO 3 ; Take CaF with a mass ratio of 1:35:35:1 2 , NaCl, KCl, Na 3 AlF 6 A total of 10g was mixed to form a flux, and mixed with WO 3 Mix to form a mixed powder; ball mill the mixed powder under vacuum protection, the ball milling speed is 350rpm, the ball-to-material ratio is 10:1, and the ball milling time is 8h; the ball-milled mixed powder is preheated to 400°C for 30min, and the Al-10Mn intermediate The alloy is heated to 800°C in a resistance furnace to melt, and the preheated mixed powder is wrapped with aluminum foil and pressed into the melt, and treated by acoustic-magnetic coupling for 10 minutes; the ultrasonic power is 1KW, and the frequency is 10KHz; Put it in place for 5 minutes to remove the slag and take it out of the furnace for casting.

Embodiment 2

[0033] Weigh 90g Al-Mn master alloy, 10g WO 3 ; Take by weighing CaF with a mass ratio of 10:45:45:10 2 , NaCl, KCl, Na 3 AlF 6 A total of 20g was mixed to form a flux, and mixed with WO 3 Mix to form a mixed powder; ball mill the mixed powder under vacuum protection, the ball milling speed is 350rpm, the ball to material ratio is 10:1, and the ball milling time is 8h; the mixed powder after ball milling is preheated to 500°C for 120min, and the Al-10Mn intermediate The alloy is heated to 800°C in a resistance furnace to melt, and the preheated mixed powder is wrapped with aluminum foil and pressed into the melt, and treated by acoustic-magnetic coupling for 10 minutes; the ultrasonic power is 1KW, and the frequency is 10KHz; Set it for 10 minutes to remove the slag and take it out of the furnace for casting.

Embodiment 3

[0035] Weigh 95g Al-Mn master alloy, 5g WO 3 ; Take by weighing CaF with a mass ratio of 3:38:38:3 2 , NaCl, KCl, Na 3 AlF 6 A total of 15g was mixed to form a flux and mixed with WO 3Mix to form a mixed powder; ball mill the above mixed powder under vacuum protection, the ball milling speed is 350rpm, the ball to material ratio is 10:1, and the ball milling time is 8h; the mixed powder after ball milling is preheated to 450°C for 90min, and the Al-10Mn The master alloy is melted by heating to 800°C in a resistance furnace, and the preheated mixed powder is wrapped with aluminum foil and pressed into the melt, and treated by acoustic-magnetic coupling for 10 minutes; the ultrasonic power is 1KW, and the frequency is 10KHz; after the treatment is completed Stand still for 15 minutes, remove the slag and take it out of the furnace for casting.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com