Method for refining pseudoionone through molecular distillation

A pseudo-ionone and molecular distillation technology is applied in the field of separating and refining pseudo-ionone by molecular distillation technology, which can solve the problems of easy oxidation, polymerization, impure product aroma and high production cost of pseudo-ionone, and achieve The effect of low production intensity, low production cost and short operation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

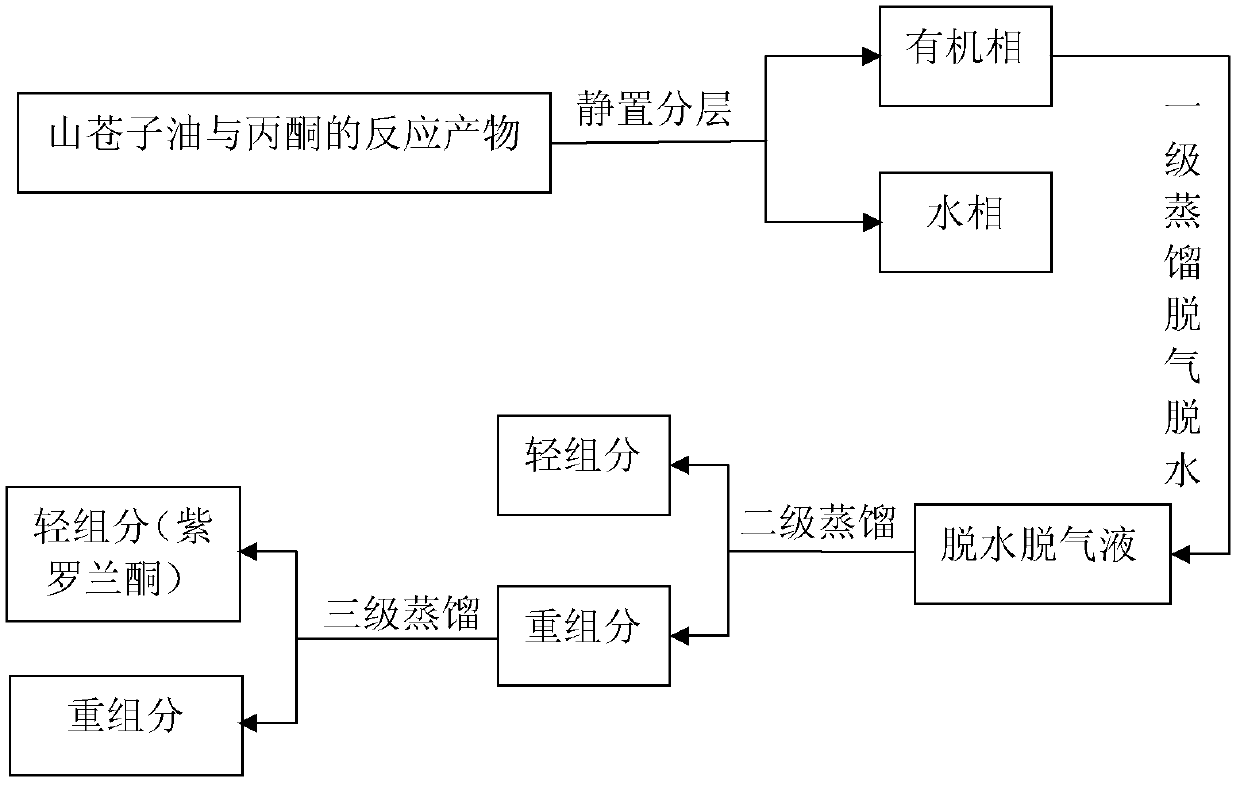

[0026] The steps and conditions of a method for purifying pseudoionone by molecular distillation are as follows:

[0027] (1) Standing for stratification: pump the aldehyde-ketone condensation reaction product of 5kg of Litsea cubeba oil and acetone under alkaline conditions into a settling kettle kept at 20°C, and collect the upper organic phase after standing and settling for 10 minutes;

[0028] (2) First-level thin-film distillation dehydration and degassing: the collected upper organic phase is pumped into a first-level thin-film distillation column at a flow rate of 40ml / min for dehydration and degassing. The first-stage distillation heating temperature is 60℃, and the vacuum degree is 5×10 4 ~9×10 4 Pa, the film scraping speed is 100rpm, and the condensation temperature is 5℃;

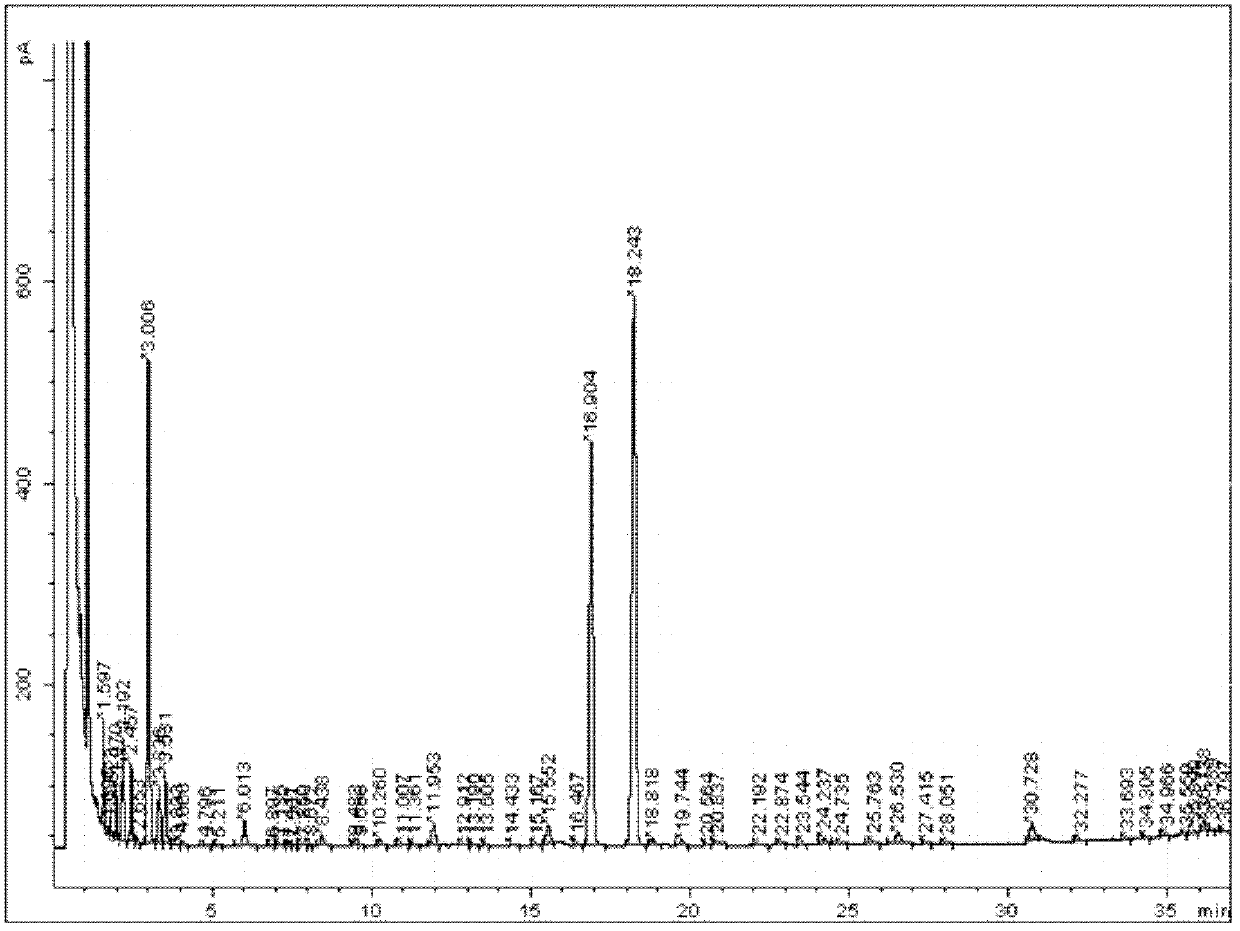

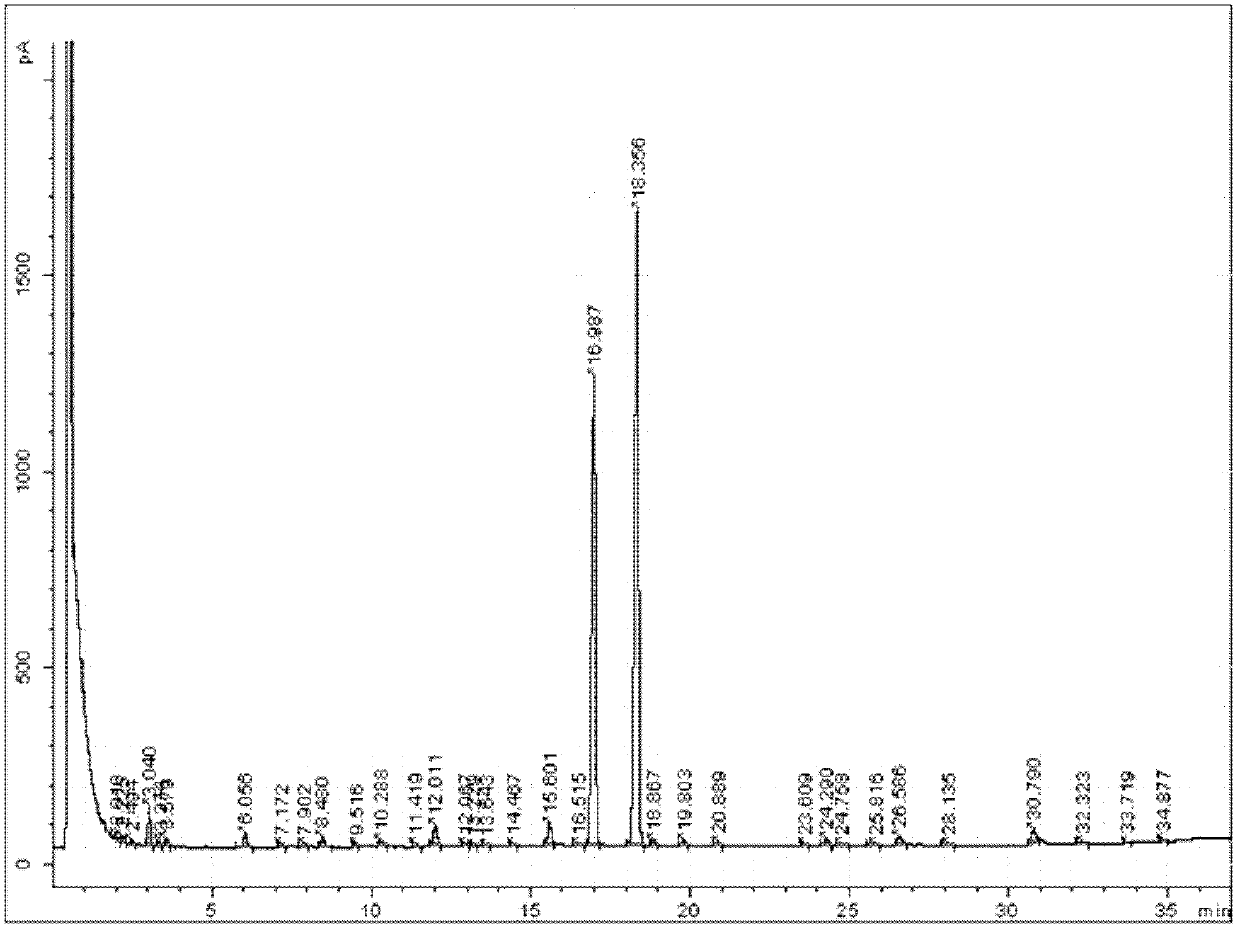

[0029] (3)Secondary molecular distillation separation: the dehydrated and degassed liquid is pumped into the second molecular distiller at a flow rate of 40ml / min for distillation separation, and the l...

Embodiment 2

[0032] The steps and conditions of a method for purifying pseudoionone by molecular distillation are as follows:

[0033] (1) Standing for stratification: Pump the aldehyde-ketone condensation reaction product of 5 kg of Litsea cubeba oil and acetone under alkaline conditions into a settling kettle kept at 30°C. After standing and settling for 30 minutes, collect the upper organic phase;

[0034] (2) First-level thin-film distillation dehydration and degassing: The collected upper organic phase is smoothly pumped into the first-level thin-film distillation column at a flow rate of 40ml / min for dehydration and degassing. The heating temperature of the first-stage distillation is 80℃ and the vacuum degree is 7×10 4 Pa, the scraping speed is 200rpm, and the condensation temperature is 8℃;

[0035] (3)Secondary molecular distillation separation: pump the dehydrated and degassed liquid into the second molecular distiller at a flow rate of 40ml / min for distillation separation to obtain 1.2...

Embodiment 3

[0038] The steps and conditions of a method for purifying pseudoionone by molecular distillation are as follows:

[0039] (1) Standing for stratification: 5kg of aldehydes and ketone condensation reaction products of Litsea cubeba oil and acetone under alkaline conditions are pumped into a settling kettle kept at 50°C, and after standing and settling for 60 minutes, the upper organic phase is collected;

[0040] (2) First-level thin-film distillation dehydration and degassing: The collected upper organic phase is pumped into a first-level thin-film distillation column at a flow rate of 40ml / min for dehydration and degassing. The first-stage distillation heating temperature is 90℃ and the vacuum degree is 5×10 4 Pa, the film scraping speed is 300rpm, and the condensation temperature is 12℃;

[0041] (3)Secondary molecular distillation separation: pump the dehydrated and degassed liquid into the second molecular distiller at a flow rate of 40ml / min for distillation separation, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com