Plant ash removing device

A plant and ash collection technology, applied in suction nozzles, cleaning equipment, vacuum cleaners, etc., can solve the problems of high labor intensity, deterioration of production environment, and ash on the ground, and achieve good cleaning effect, wide cleaning range and strong adaptability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

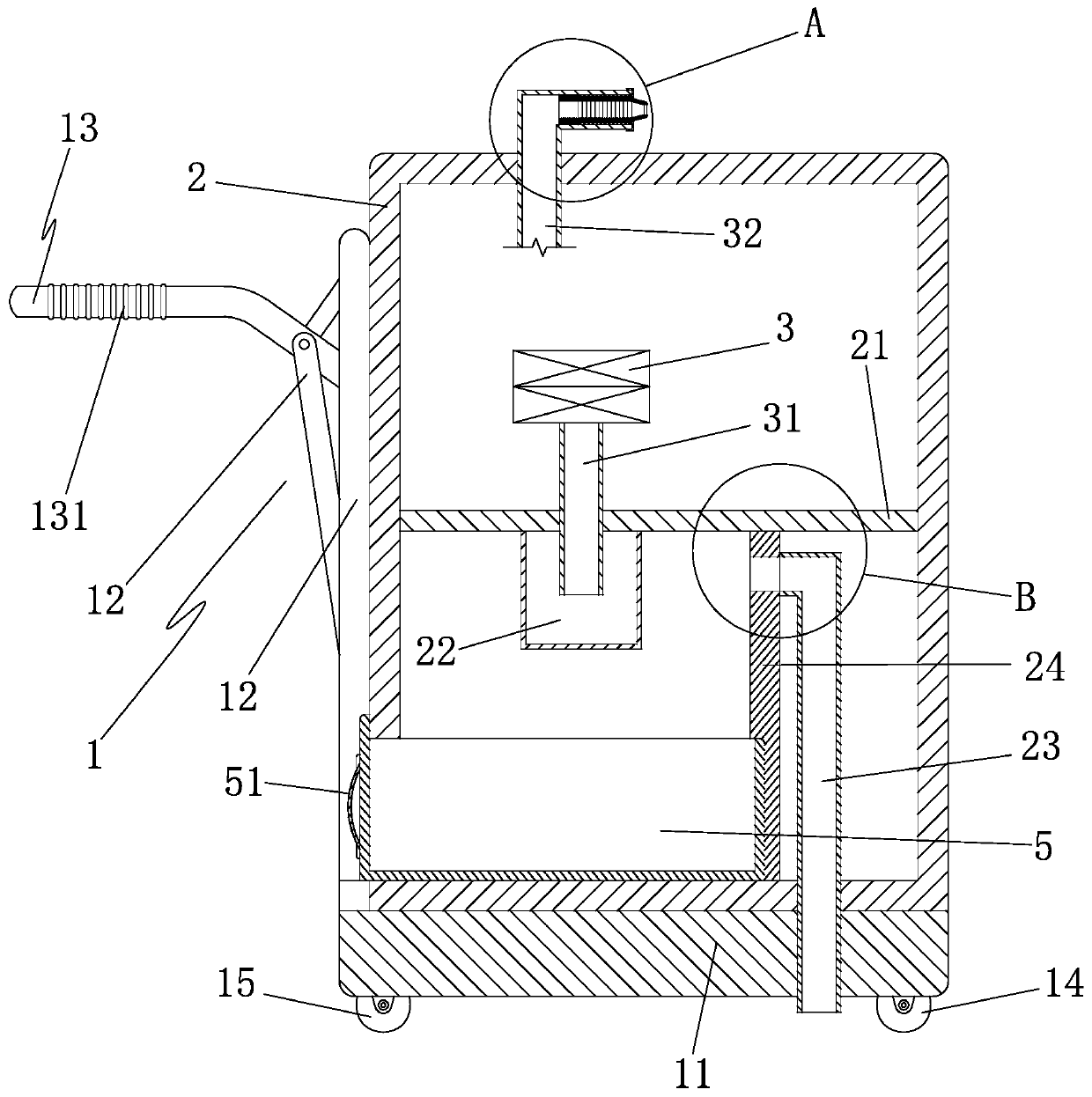

[0033] Example 1: as Figure 1 to Figure 4 shown,

[0034] An ash removal device for a factory building, comprising a cart 1, a casing 2 disposed on the cart, a dust suction motor 3 disposed in the casing, and a diaphragm 21 disposed in the casing;

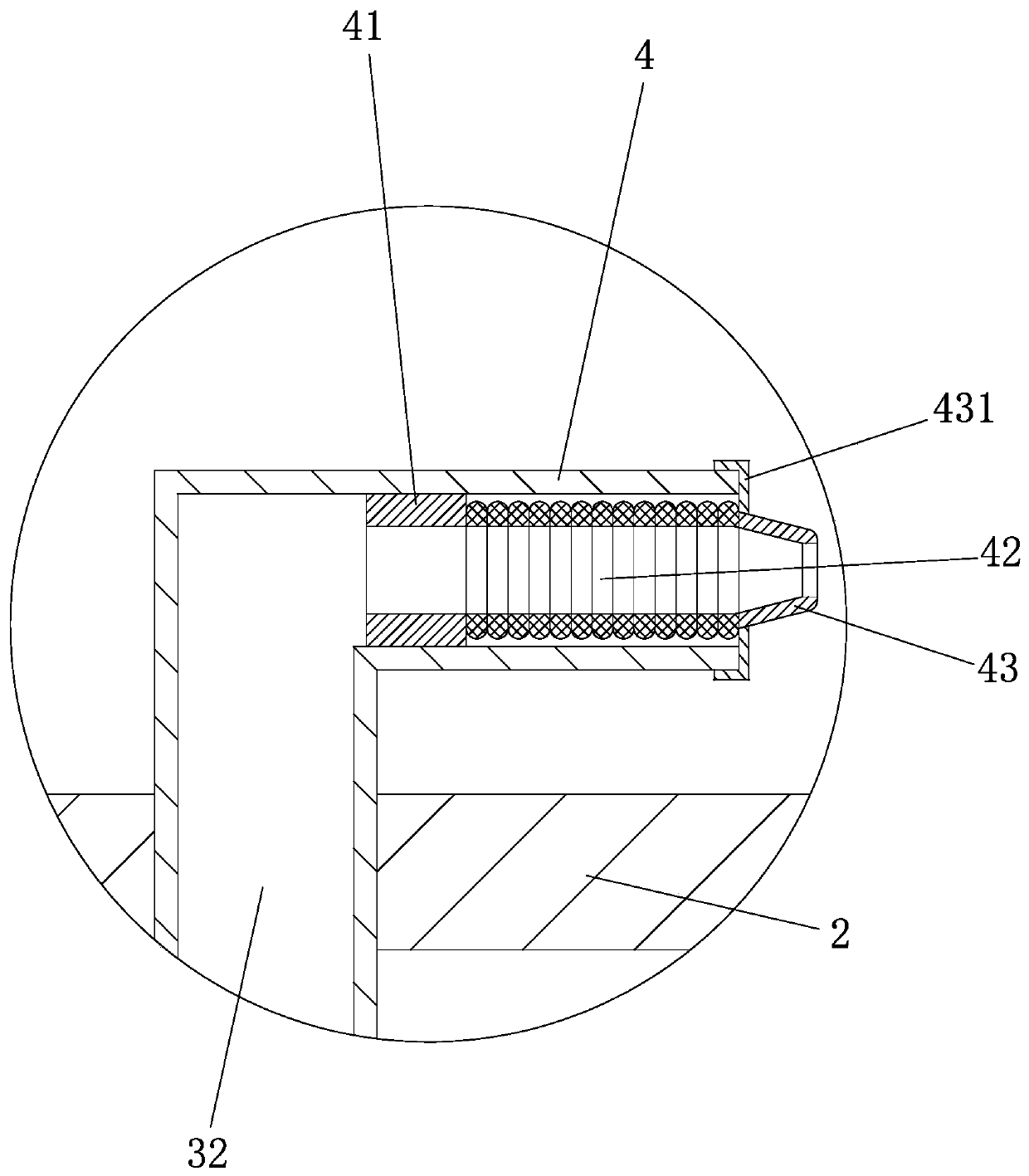

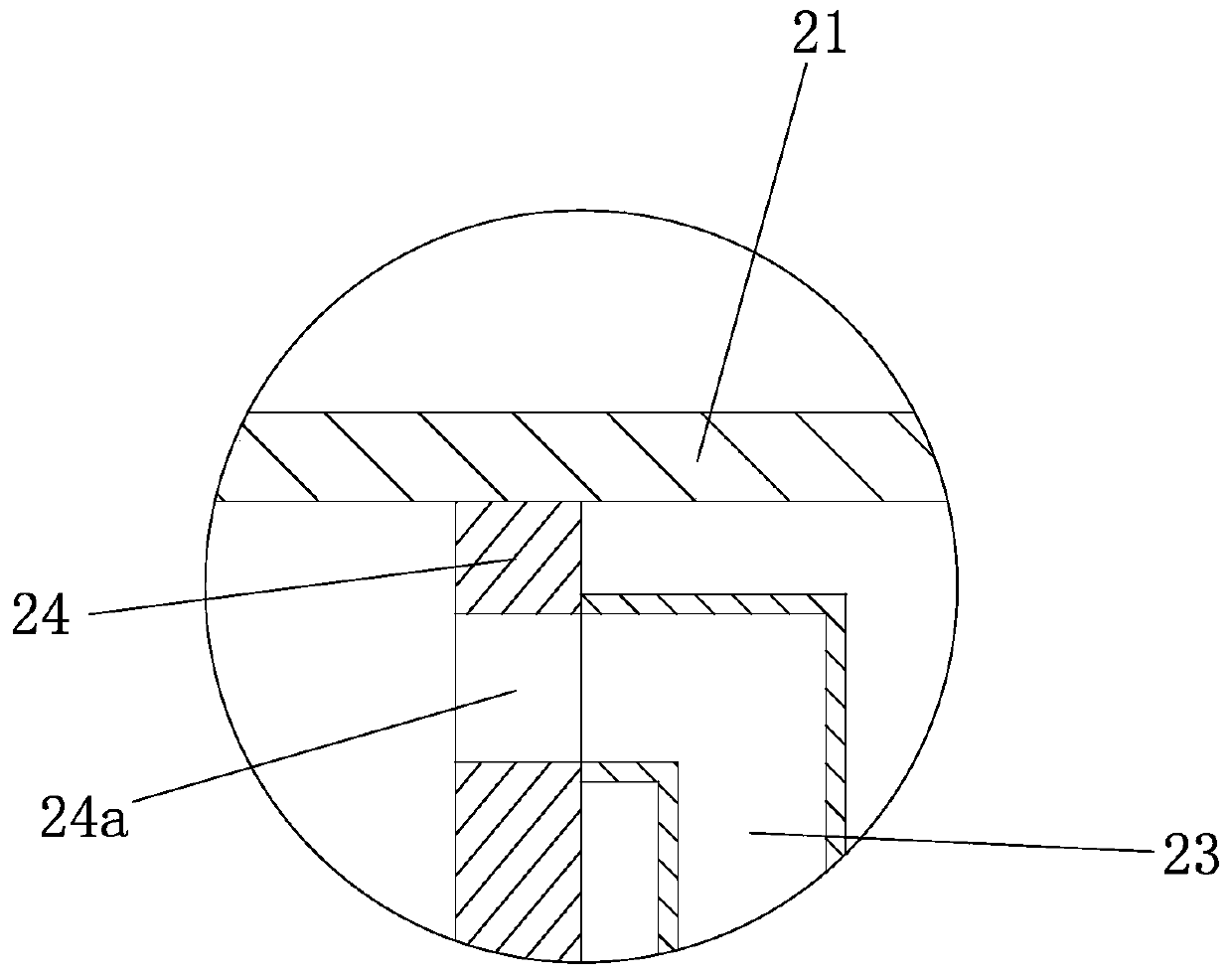

[0035] The diaphragm divides the interior of the casing into an upper cabin and a lower cabin, the vacuuming motor is located in the upper cabin, and the lower cabin is provided with a filter cartridge 22 with an upper end open, and the upper end of the filter cartridge is sealed with the diaphragm. The board is provided with an air inlet pipe 31 passing through the diaphragm, the upper end of the air inlet pipe is connected to the air inlet end of the vacuum motor, the lower end of the air inlet pipe is located in the filter cartridge, and the casing is provided with a ash cleaning port that communicates with the lower engine room and a ash cleaning door that can cover the ash cleaning port. The casing is provided with an exhaus...

Embodiment 2

[0043] Example 2: Based on Example 1, as Figure 5 to Figure 10 shown,

[0044] The upper engine room is provided with a switching and cleaning structure, which includes a transverse sleeve 61, a transverse core column 62 that is slidingly and sealedly matched with the transverse sleeve, an inner rod 63 connected to the transverse core column, and an inner rod slidably connected to the casing. The seat plate 64 and the switching cylinder 65 fixed with the diaphragm, the inner rod is connected to the inner seat plate, and the inner seat plate is provided with a number of outer rods 641 which pass through the casing and are slidingly and sealingly matched with the casing, and the outer rods are arranged in parallel , the outer casing is provided with a touch wall plate 66 for contacting the wall, and the touch wall plate is connected to each outer rod;

[0045] The switching cylinder is provided with a switching master piston 651 which is slidingly and sealingly matched with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com