Cleaning device for glass production

A technology for cleaning device and glass, applied in the direction of cleaning method using tools, cleaning method using liquid, cleaning method using gas flow, etc., can solve problems such as optical defects, glass surface damage, inconvenient glass cleaning, etc. The effect of wide, water saving and high cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Unless otherwise stated, the terms used herein have meanings commonly understood by those skilled in the art.

[0026] The present invention will be described in detail below in conjunction with the embodiments and accompanying drawings.

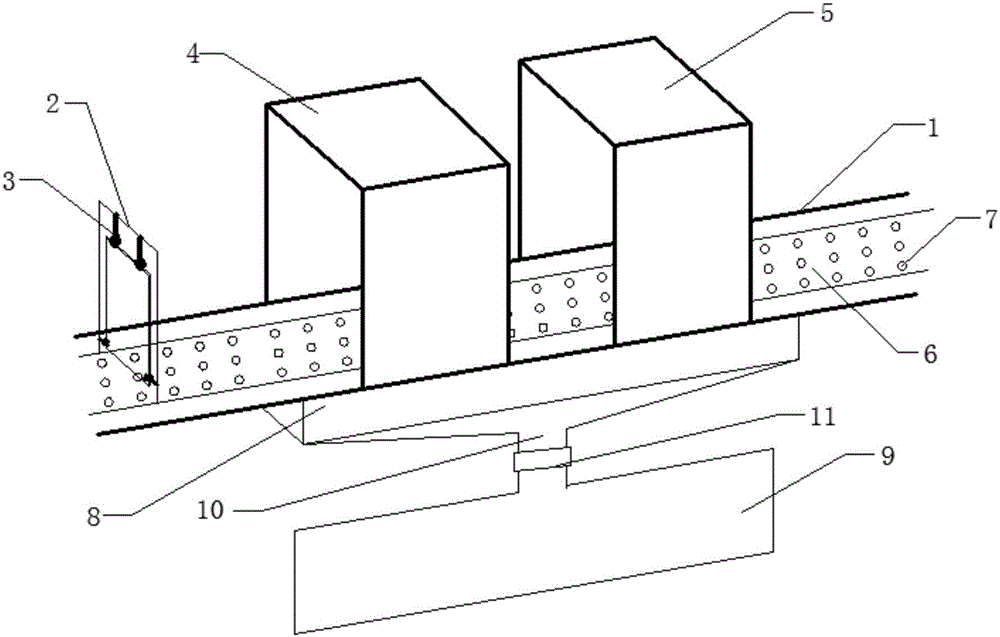

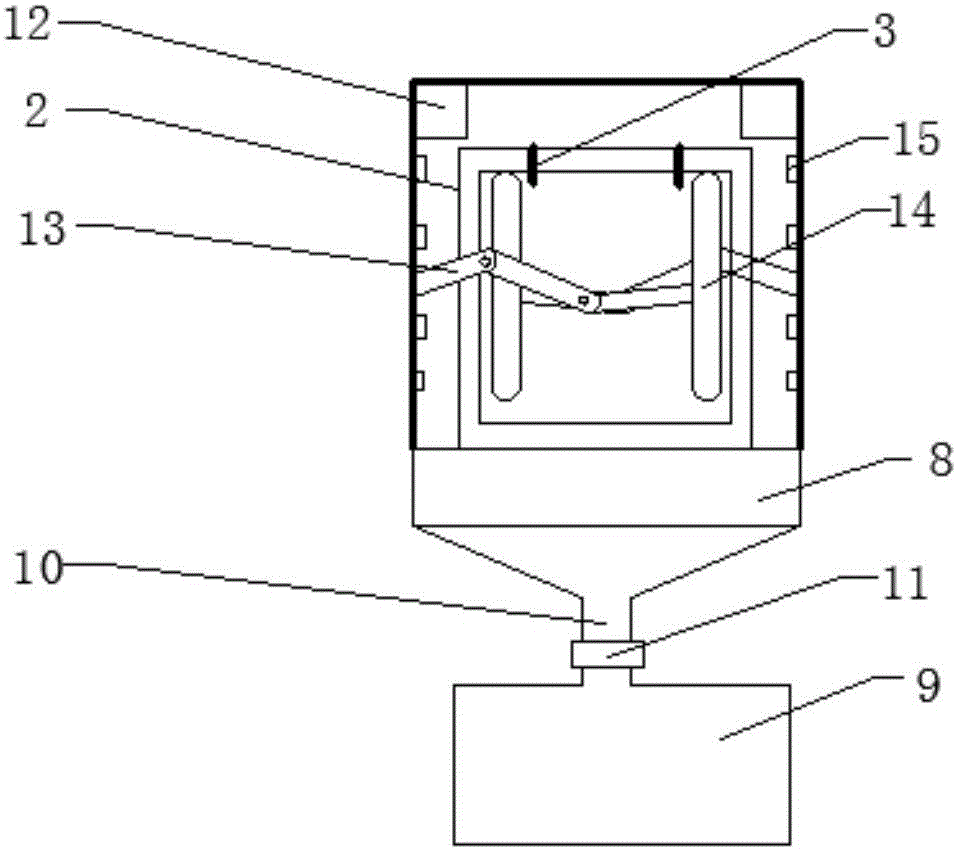

[0027] A cleaning device for glass production, including a workbench 1, a support 2, a handle 3, a washing room 4, a drying room 5, a conveyor belt 6, and a water collecting device 8;

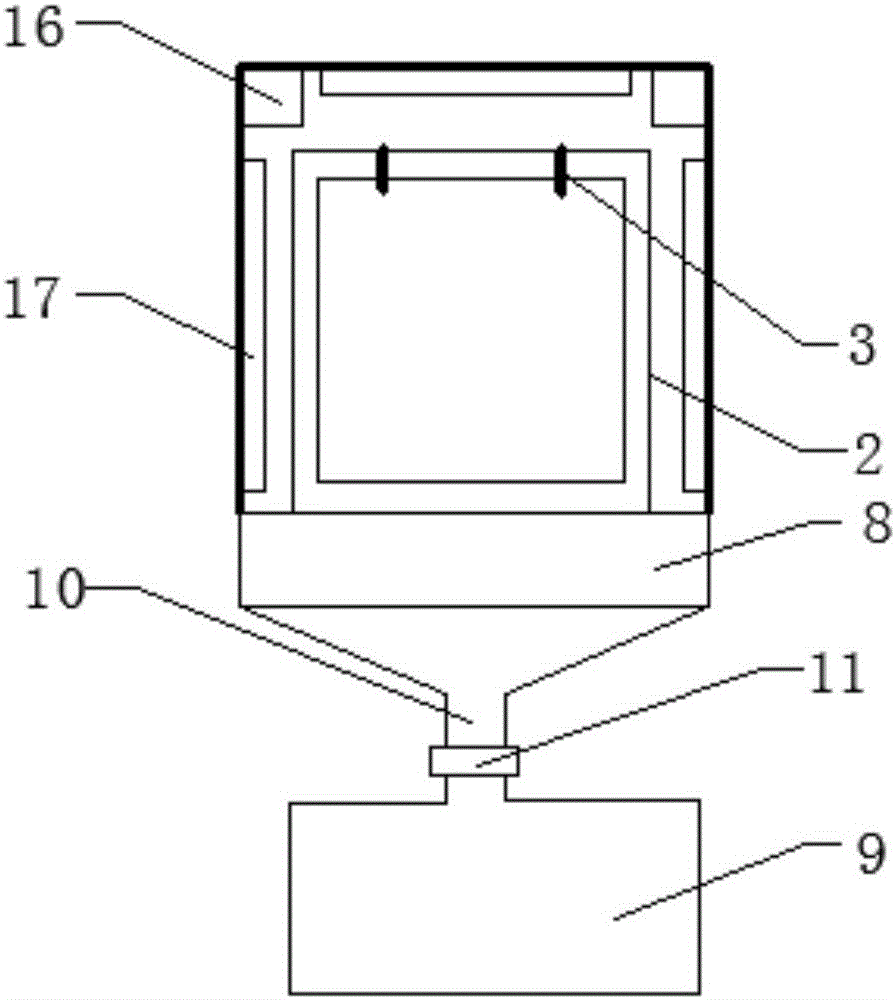

[0028] The workbench 1 is sequentially provided with a washing chamber 4 and a drying chamber 5 from left to right, the inner side wall of the drying chamber 5 is provided with a heating device 17, and the four angles at the top of the drying chamber 5 are all A second air knife 16 is provided, and the second air knife 16 is connected with a high-pressure blower; the left and right sides of the washing chamber 4 and the drying chamber 5 are provided with movable doors, and the table top of the workbench 1 is detachable filter screen; the surface of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com