Lithium ion battery, laser manufacturing method thereof and laser washing device

A technology of lithium-ion batteries and manufacturing methods, applied in the direction of electrolyte storage battery manufacturing, electrode manufacturing, cleaning methods and appliances, etc., can solve the problems of poor high-temperature performance and low cycle life of lithium manganate, and achieve simplified manufacturing process and high adaptability , a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

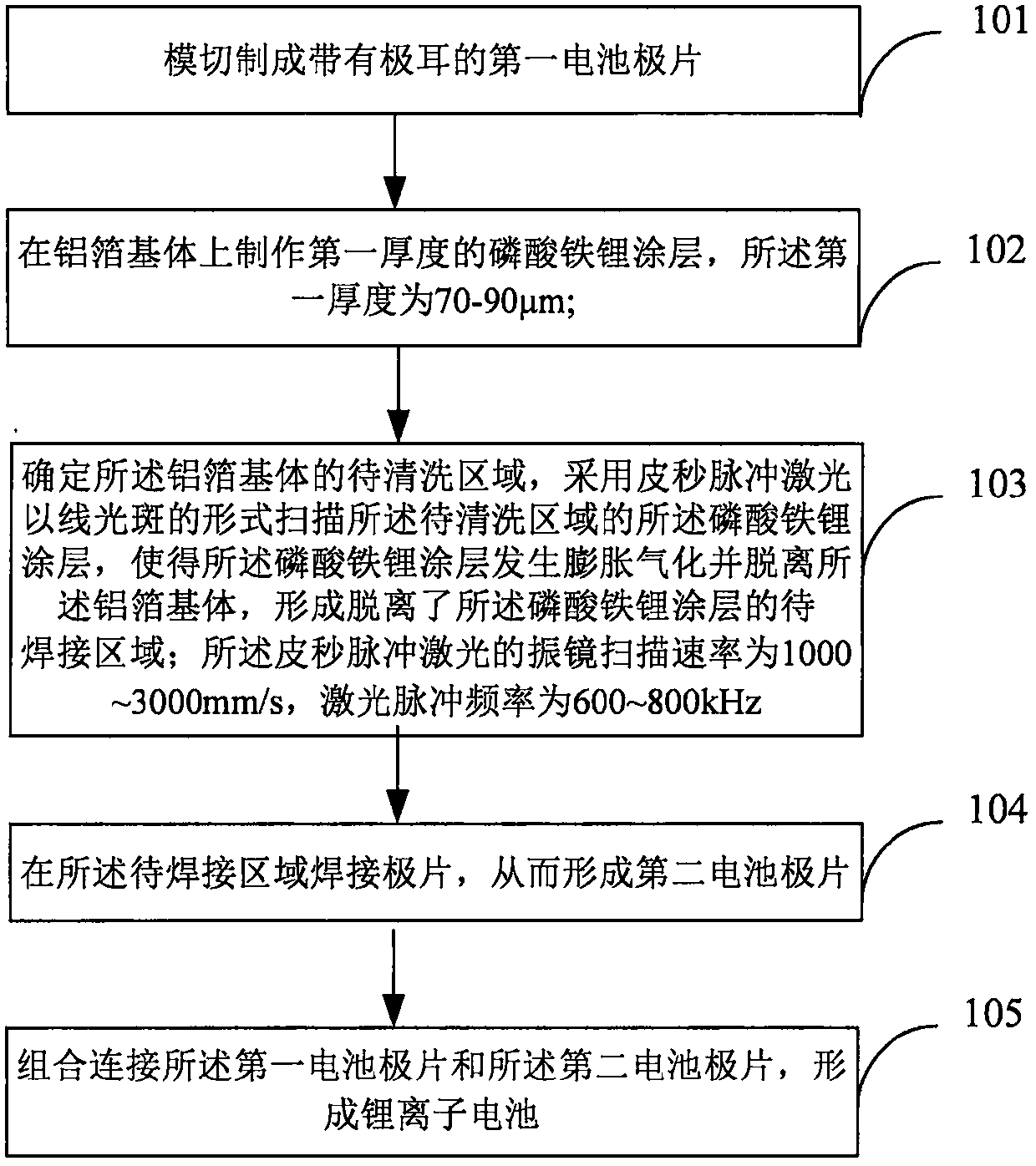

[0040] figure 1 It is a flow chart of the steps of the method embodiment of the present invention, such as figure 1 As shown, the present invention provides a kind of laser manufacturing method of lithium ion battery, comprising:

[0041] Step 101, die-cutting to form the first battery pole piece with tabs;

[0042] Step 102, making a first thickness of lithium iron phosphate coating on the aluminum foil substrate, the first thickness being 70-90 μm;

[0043] Step 103, determine the area to be cleaned of the aluminum foil substrate, and scan the lithium iron phosphate coating in the area to be cleaned by using a picosecond pulse laser in the form of a line spot, so that the lithium iron phosphate coating expands and gasifies And detached from the aluminum foil substrate to form a region to be welded detached from the lithium iron phosphate coating; the scan rate of the galvanometer of the picosecond pulse laser is 1000-3000mm / s, and the laser pulse frequency is 600-800kHz; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| power | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com