Multi-element composite high-pressure water jet cleaning device

A technology of high-pressure water jet and cleaning device, which is applied in the direction of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc. The aging of seals and other problems can be solved, and the effect of fast speed, guaranteed jet pressure and jet speed, and cost saving can be achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

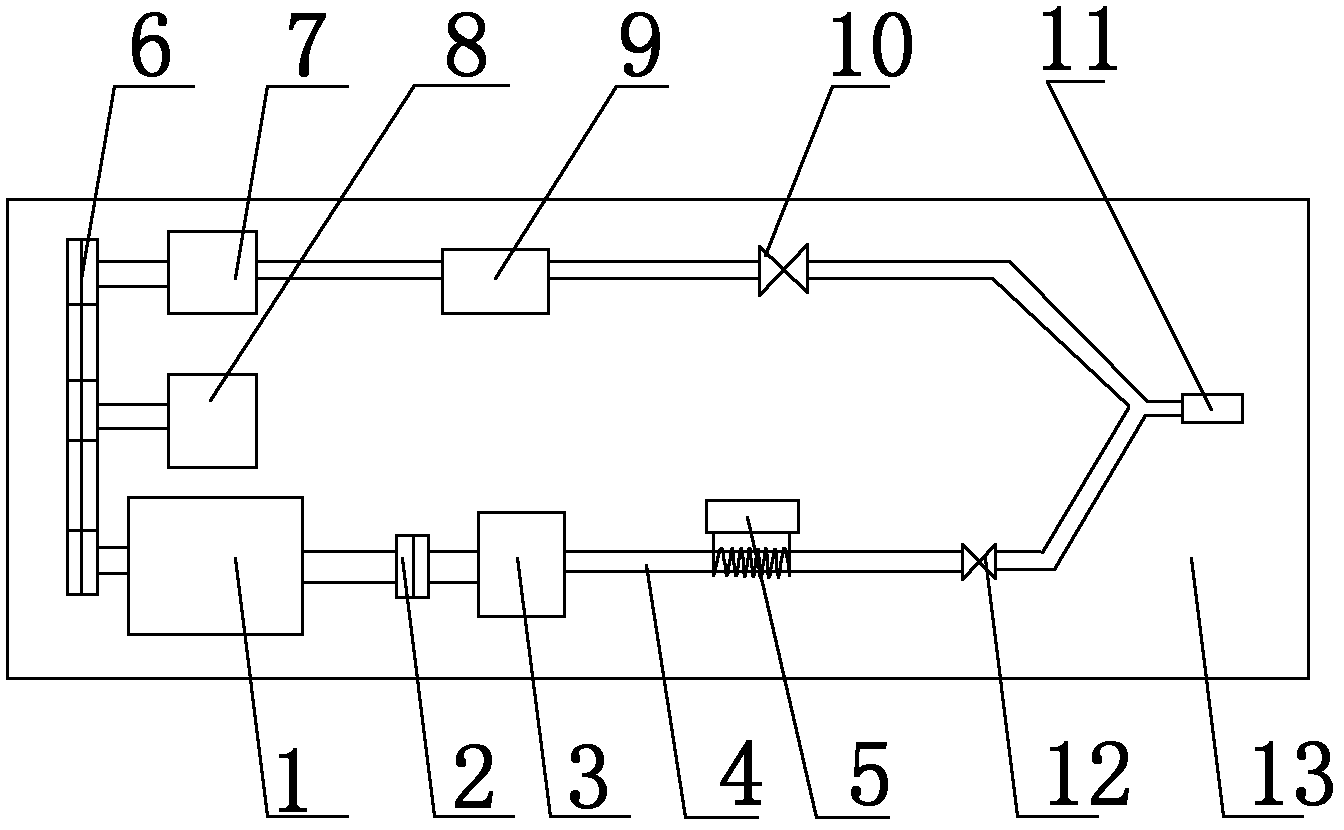

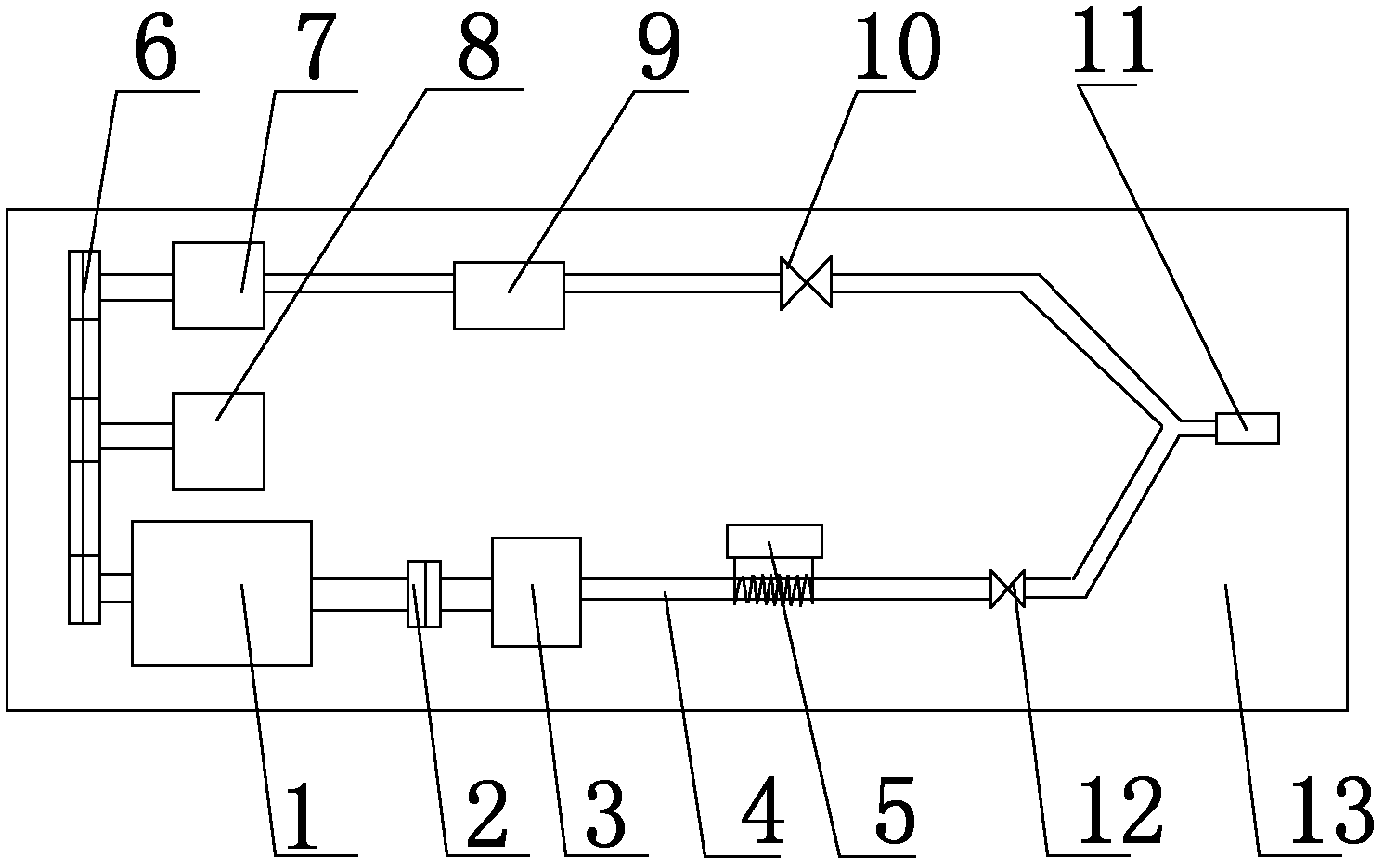

[0009] The present invention will be further described below in conjunction with accompanying drawing:

[0010] Depend on figure 1 As shown, the multi-component composite high-pressure water jet cleaning device mainly includes a diesel engine 1, a high-pressure cleaning pump 3, a numerically controlled electromagnetic heating system 5, a generator 8, an air pump 7, and a pulse control system 9. The diesel engine 1 is used as a power source and connected through a clutch 2. High-pressure cleaning pump 3, the water outlet end of high-pressure cleaning pump 3 is connected to high-pressure check valve 12 through high-pressure steel pipe 4, wherein, the high-pressure steel pipe 4 between the high-pressure cleaning pump 3 and high-pressure check valve 12 passes through numerical control electromagnetic heating system 5 , so that the high-pressure water in the high-pressure steel pipe 4 forms a high temperature to improve the cleaning effect; the output shaft at the rear end of the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com