Device for cleaning ceramic tile wall

A technology for cleaning devices and walls, used in cleaning equipment, cleaning machinery, carpet cleaning, etc., can solve the problems of complex structure, large total wall area, general cleaning effect, etc., and achieve good cleaning effect, wide cleaning range, and good cleaning effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

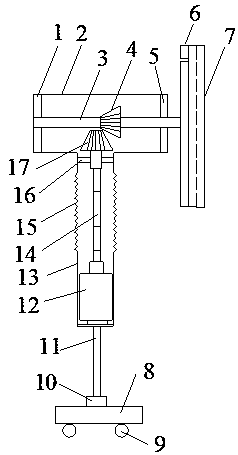

[0031] like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, a ceramic tile wall cleaning device includes a base 8, a traveling wheel 9 is arranged at the bottom of the base 8, and a braking device is provided on the traveling wheel 9. A hydraulic cylinder 10 is embedded on the base 8 , and the end of the output shaft 11 of the hydraulic cylinder 10 is fixedly connected to the bottom of the motor housing 13 . In this embodiment, the hydraulic cylinder 10 and its output shaft 11 serve as a height adjustment device.

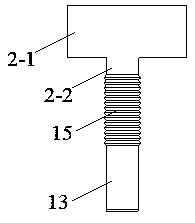

[0032] The upper part of the motor housing 13 is threaded to the telescopic housing 15, and the upper part of the telescopic housing 15 is threaded to the T-shaped housing 2, and the T-shaped housing 2 includes a horizontal part 2-1 and a vertical part 2-2. In this embodiment, the flexible casing 15 adopts bellows.

[0033] Motor 12 is fixedly arranged in motor housing 13, and the drive shaft of motor 12 is vertical; The telescopic shaft 14 ...

Embodiment 2

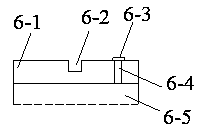

[0042] In addition to the structural features of Embodiment 1, such as Figure 6 As shown, two sets of lifting devices are arranged between the base 8 and the horizontal part 2-1 of the T-shaped housing 2, and the two sets of lifting devices are respectively the second hydraulic cylinder 18 and the second hydraulic cylinder located on both sides of the motor housing 13. The cylinder output shaft 19 and the third hydraulic cylinder 20 and the third hydraulic cylinder output shaft 21 . This arrangement facilitates the expansion and contraction of the telescopic housing 15 and the telescopic shaft 14 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com