Rinse tank for rinsing semiconductor wafer

A technology for cleaning tanks and semiconductors, applied in the field of cleaning tanks, which can solve problems such as incomplete cleaning of 800 particles on a wafer, etc., and achieve the effects of strong cleaning ability, wide cleaning surface, and increased output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The implementation of the present invention will be described in detail below in conjunction with the drawings and examples, so that the realization process of how to use technical means to solve technical problems and achieve technical effects in the present invention can be fully understood and implemented accordingly.

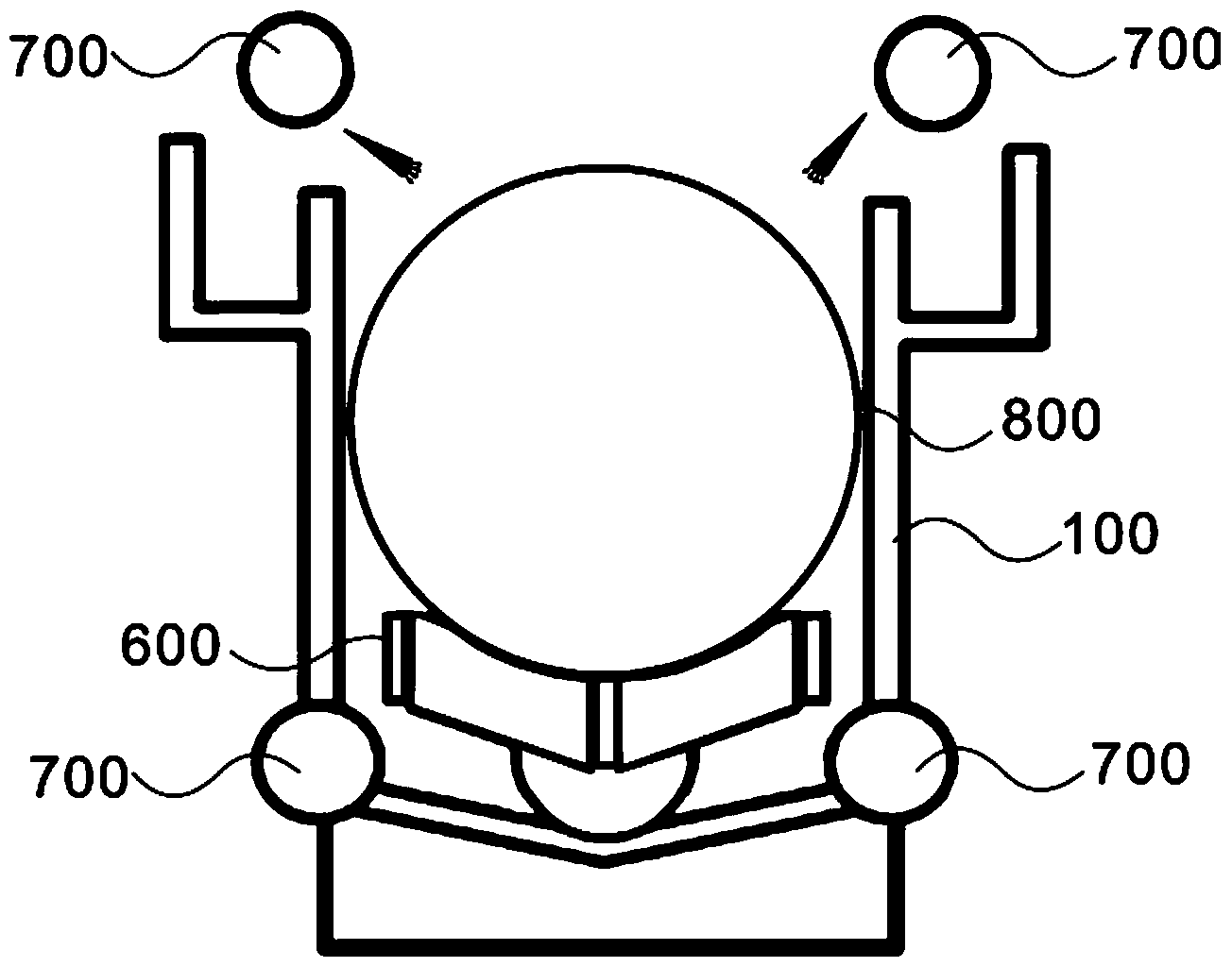

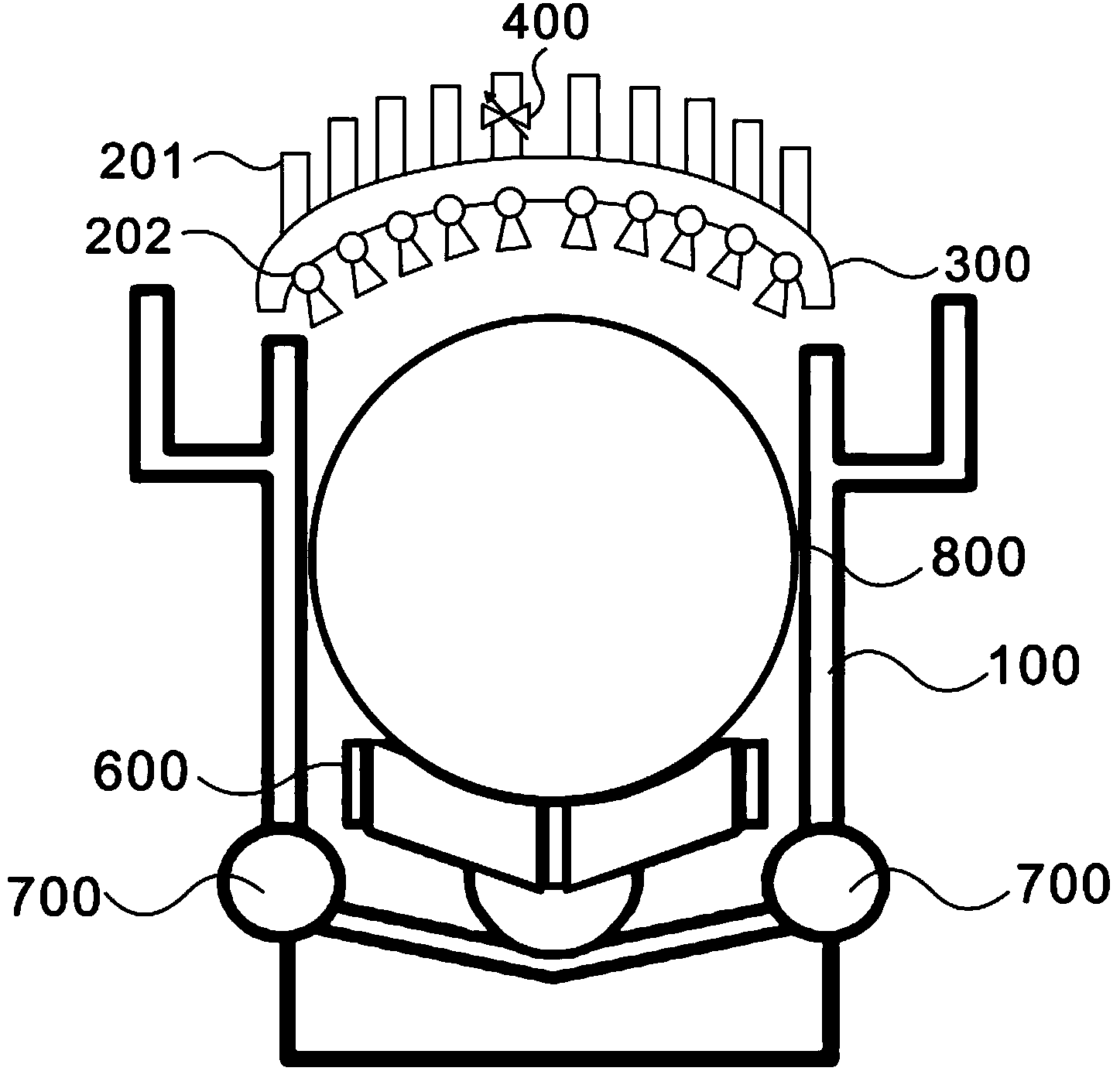

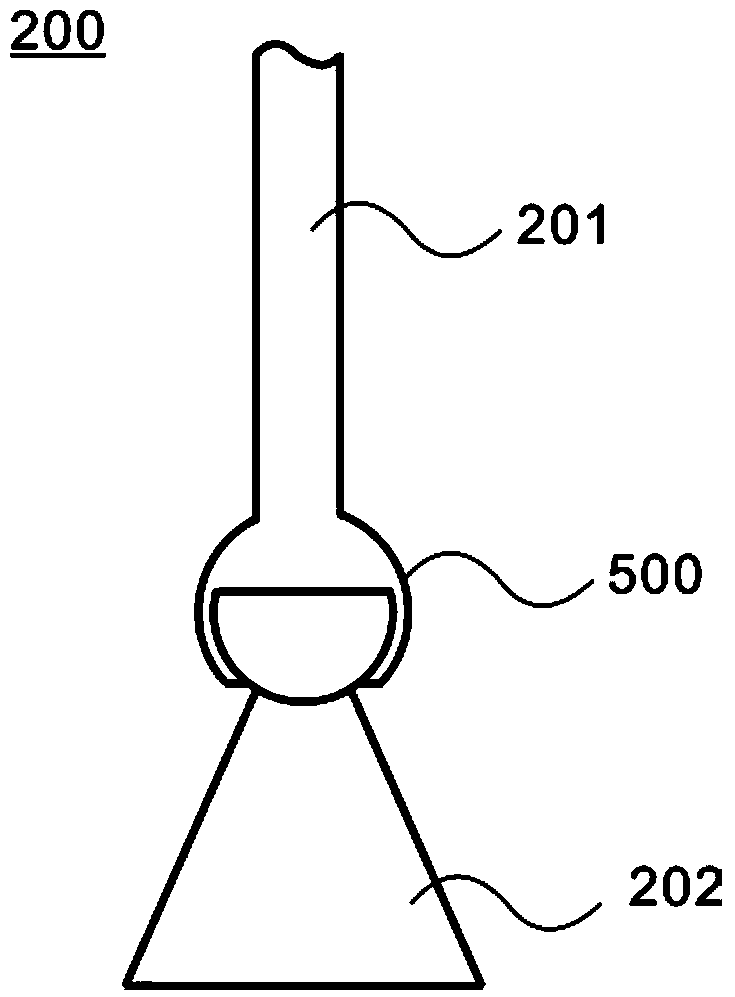

[0023] Such as figure 2 as shown, figure 2 It is a structural schematic diagram of a cleaning tank for cleaning semiconductor wafers in the present invention. The present invention provides a cleaning tank for cleaning semiconductor wafers, including a cleaning tank body 100, a spray device 200, and a top of the cleaning tank body 100. There is a tank cover 300 for closing the cleaning tank body 100, and the tank cover 300 is provided with a spray device 200 for cleaning wafers; the spray device 200 includes several spray pipes 201 and several nozzles 202 connected thereto, the nozzles 202 are evenly distributed in a matrix on the tank cover 300 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com