Steam jet flow type tank car cleaning method and device thereof

A jet-type, tanker technology, applied in cleaning methods and utensils, chemical instruments and methods, cleaning hollow objects, etc., can solve the problems of large equipment investment, high energy consumption, and damage to workers' health, and achieve a wide cleaning range and high temperature , the effect of saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

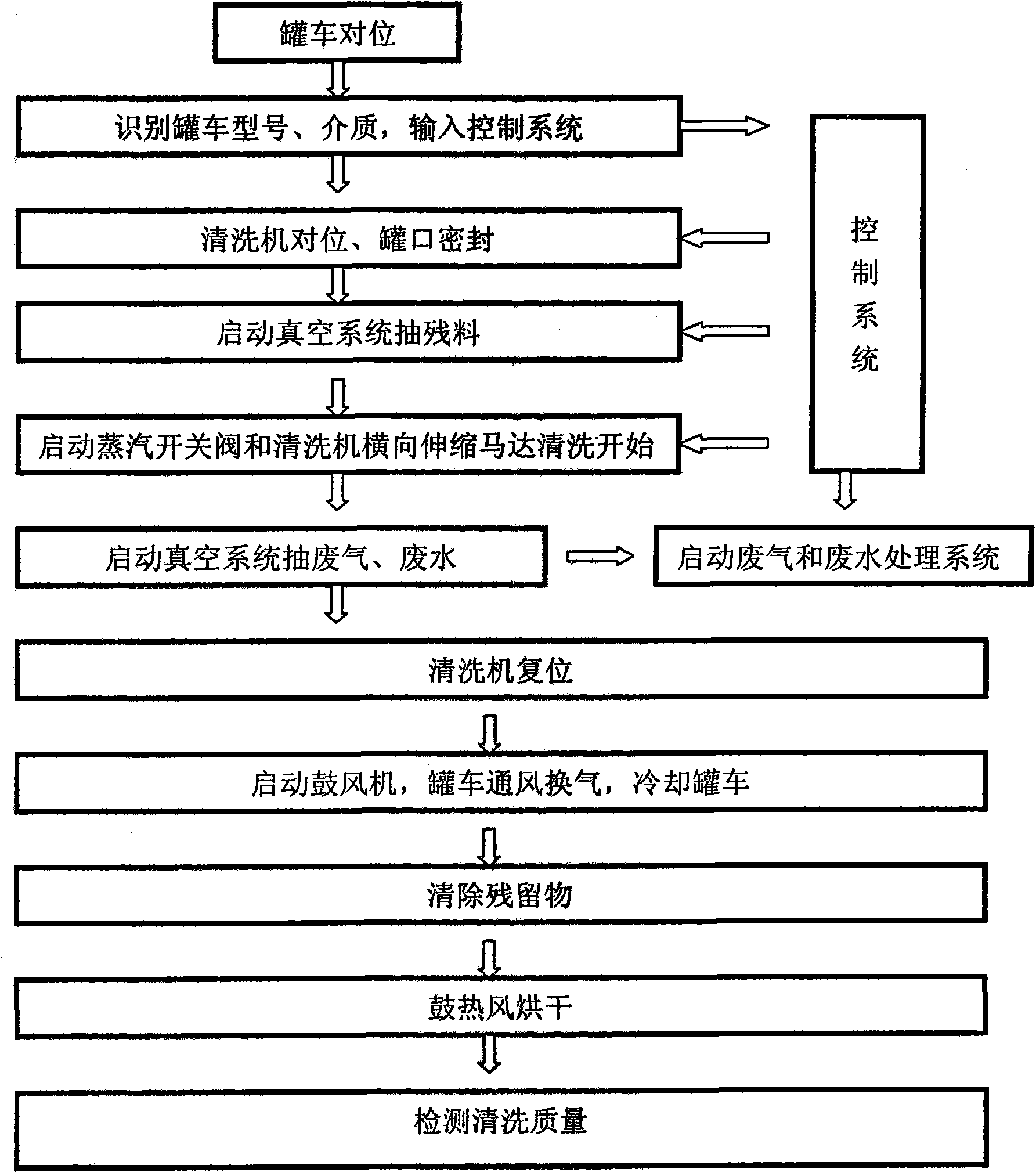

[0020] The specific implementation method of steam jet tank car cleaning is as follows (see figure 1 ):

[0021] 1. Alignment of the tank car to be cleaned;

[0022] 2. Identify the model and vehicle type of the tank car, and input the data of the long end and short end of the tank car into the control system; determine the cleaning time according to the medium condition of the inner wall of the tank car and input it into the control system;

[0023] 3. Start the vacuum system to extract the residual material;

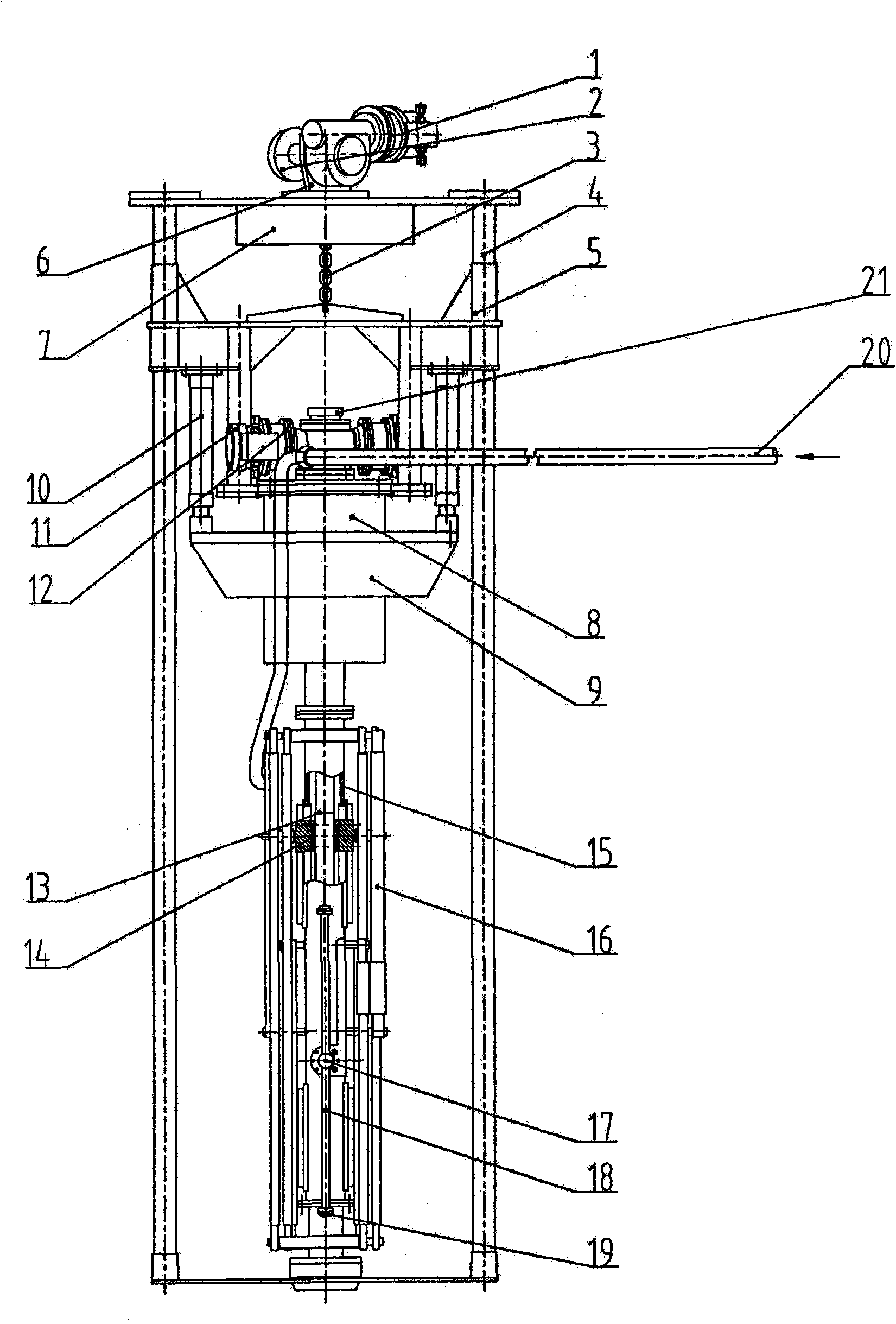

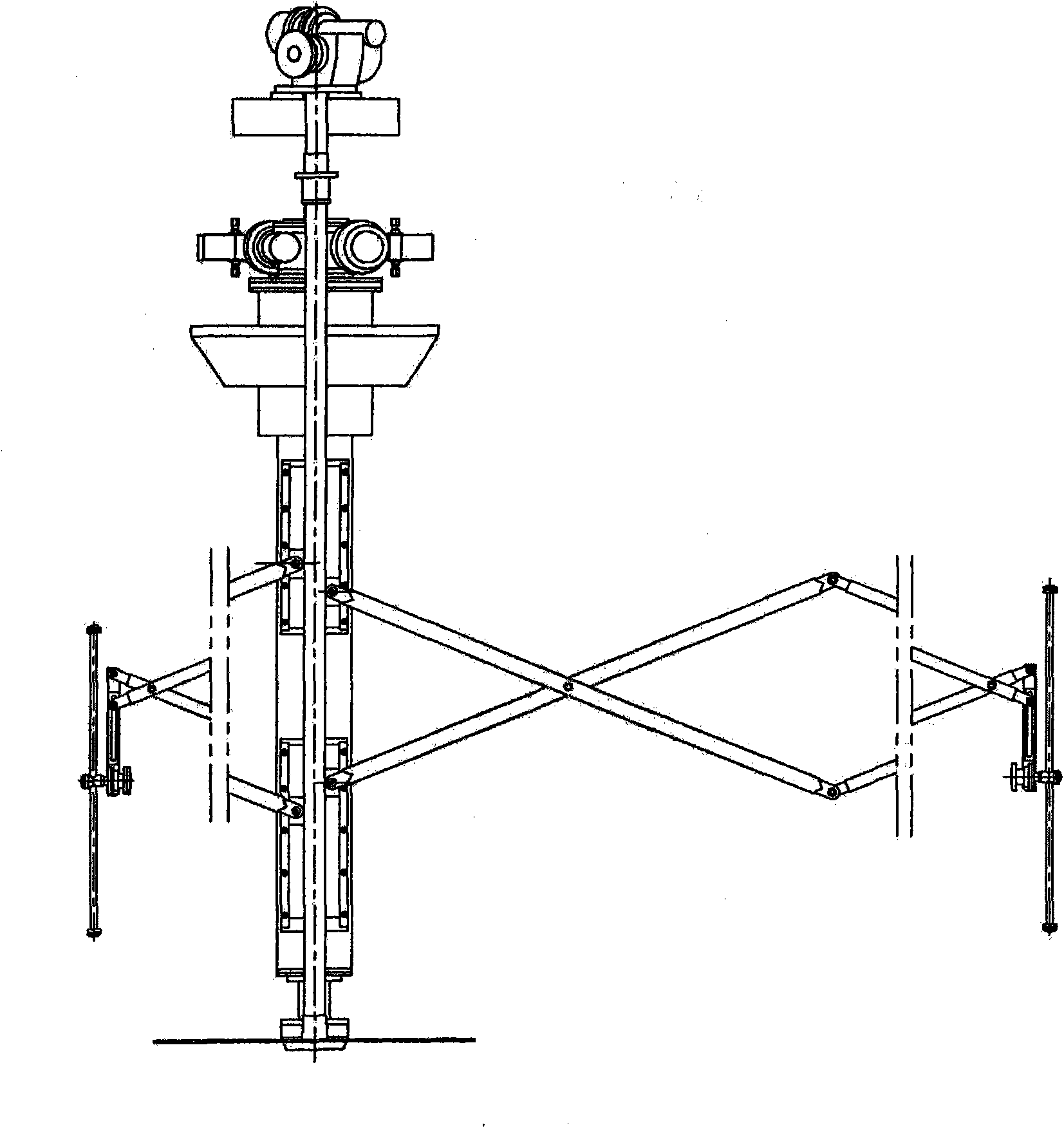

[0024] 4. The cleaning machine and the tank mouth of the tanker are aligned, the motor starts the cleaning machine’s upper and lower telescopic mechanism, the positioning guide sleeve goes down along the positioning guide rail, the conical sealing cover enters the tank opening of the tanker, the telescopic cylinder works, and the conical sealing cover is moved to the tank. Tighten the mouth of the tank;

[0025] 5. Start the steam switching valve and the horizontal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com