Laser cleaning method for marine paint

A technology for laser cleaning and ship paint, applied in cleaning methods and appliances, chemical instruments and methods, and dust removal, etc., can solve problems such as poor cleaning effect, environmental pollution, environmental pollution, etc., and achieve accurate cleaning areas, high adaptability, wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

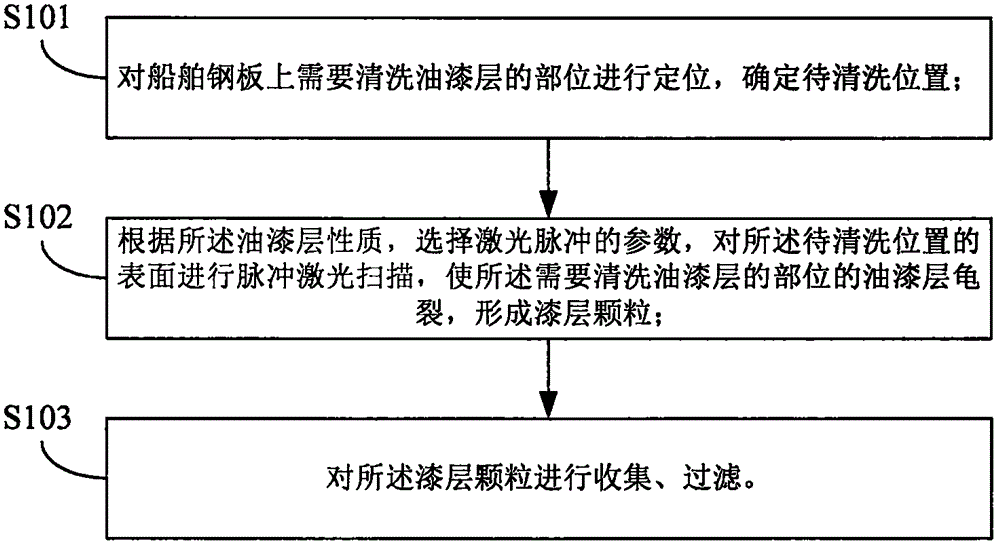

[0036] figure 1 A flow chart of the steps of the laser cleaning method for marine paint of the present invention is shown.

[0037] Such as figure 1 As shown, the embodiment of the present invention provides a laser cleaning method for ship paint, comprising the following steps:

[0038] S101, locating the part on the steel plate of the ship that needs to clean the paint layer, and determining the position to be cleaned;

[0039] S102. According to the properties of the paint layer, select the parameters of the laser pulse, and perform pulse laser scanning on the surface of the position to be cleaned, so that the paint layer at the position where the paint layer needs to be cleaned is cracked to form paint layer particles;

[0040] S103, collecting and filtering the paint layer particles.

[0041] Among them, in the laser cleaning method of ship paint of the present invention, the paint layer on the ship steel plate substrate is subjected to laser ablation and undergoes the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com