A kind of protein clay composite formaldehyde purification material and preparation method thereof

A technology of formaldehyde purification and protein clay, which is applied in the direction of chemical instruments and methods, separation methods, and other chemical processes, can solve the problems of poor formaldehyde affinity, saturated adsorption capacity of formaldehyde, and low purification efficiency, and achieve simple and large-scale preparation process. Application value, effect of mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] The specific implementation steps are as follows:

[0019] (1) Prepare an aqueous ethanol solution with anhydrous ethanol and pure water at a mass ratio of 1:1;

[0020] (2) Add protein clay powder to the ethanol solution described in step (1) in a mass ratio of 1:8, stir and disperse to form a suspension;

[0021] (3) adding the pre-hydrolyzed aminosilane solution to the suspension prepared in step (2) for graft modification, the amount of gamma-aminopropyltrimethoxysilane is 36% of the protein soil quality, and the modification temperature is 90 ℃, the modification time is 1h.

[0022] (4) washing and filtering the reaction product obtained in step (3) with ethanol and water, and drying at 60°C for 12 hours;

[0023] (5) Grinding the dried product obtained in step (4) until 97% passes through a 200-mesh sieve. That is, the protein soil composite formaldehyde purification material is obtained.

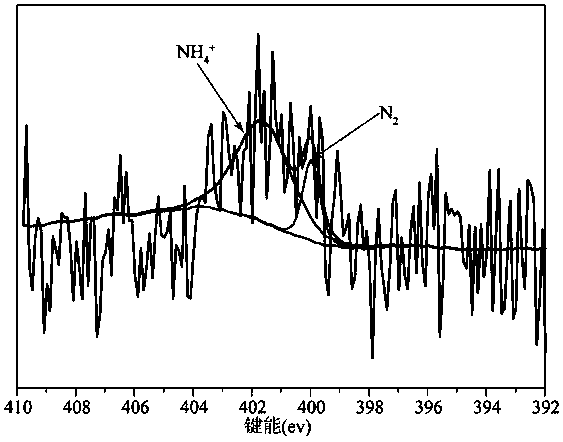

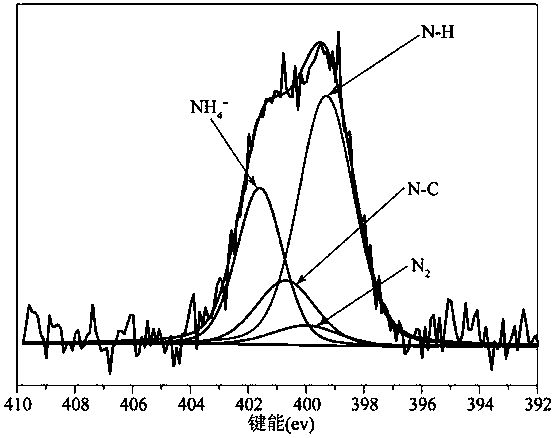

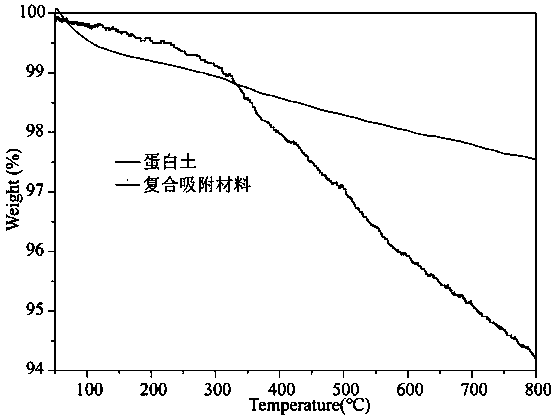

[0024] The XPS and TG figures of the protein soil composite formaldehy...

Embodiment 2

[0026] The steps are the same as those in Example 1, except that: in step (2), the protein soil powder is added to the ethanol solution described in step (1) at a mass ratio of 1:7 to stir and disperse; in step (3), the amount of silane used is protein The soil mass is 27%, the modification temperature is 80°C, and the modification time is 2h; the drying temperature in step (4) is 70°C, and the drying time is 11h.

Embodiment 3

[0028] The steps are the same as those in Example 1, except that: in step (2), the protein soil powder is added to the ethanol solution described in step (1) at a mass ratio of 1:6 to stir and disperse; in step (3), the amount of silane used is protein 18% of the soil mass, the modification temperature is 70°C, and the modification time is 3h; the drying temperature in step (4) is 80°C, and the drying time is 10h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com