A household formaldehyde remover

A cleaner and formaldehyde technology, applied in the direction of gas treatment, chemical instruments and methods, separation methods, etc., can solve the problems of dust adhesion and difficult cleaning of ventilation pipes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

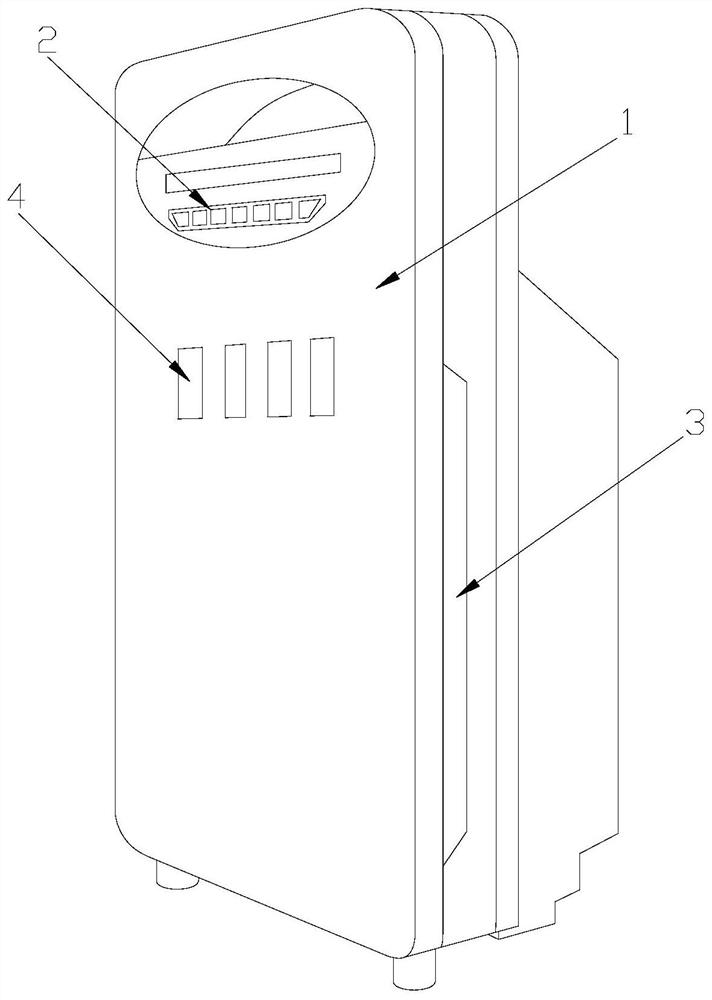

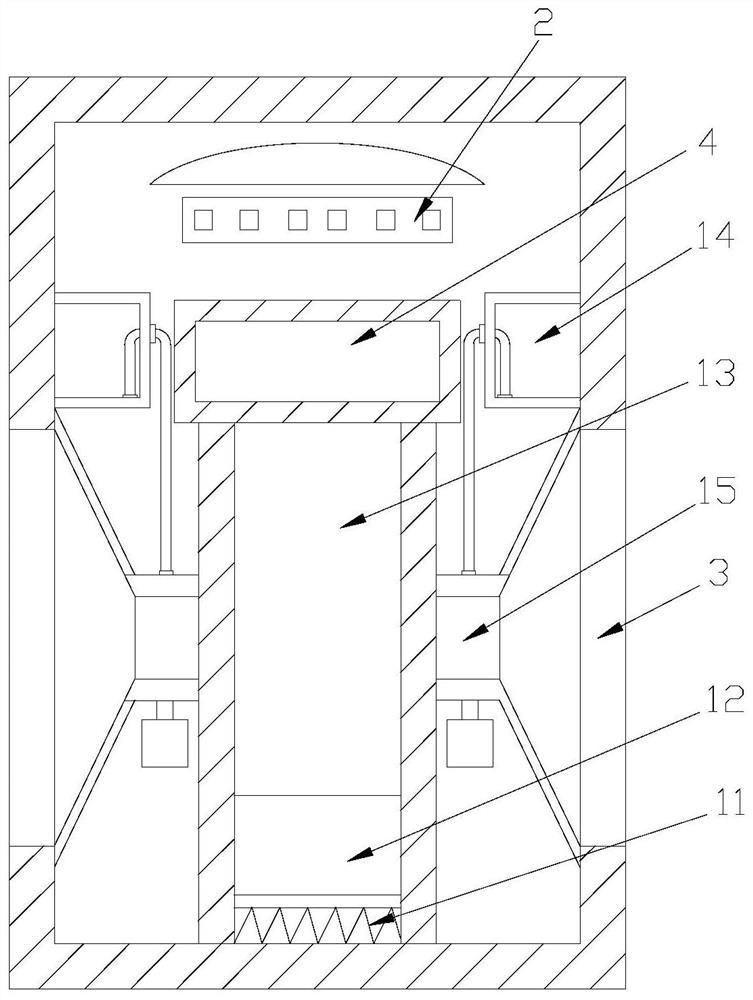

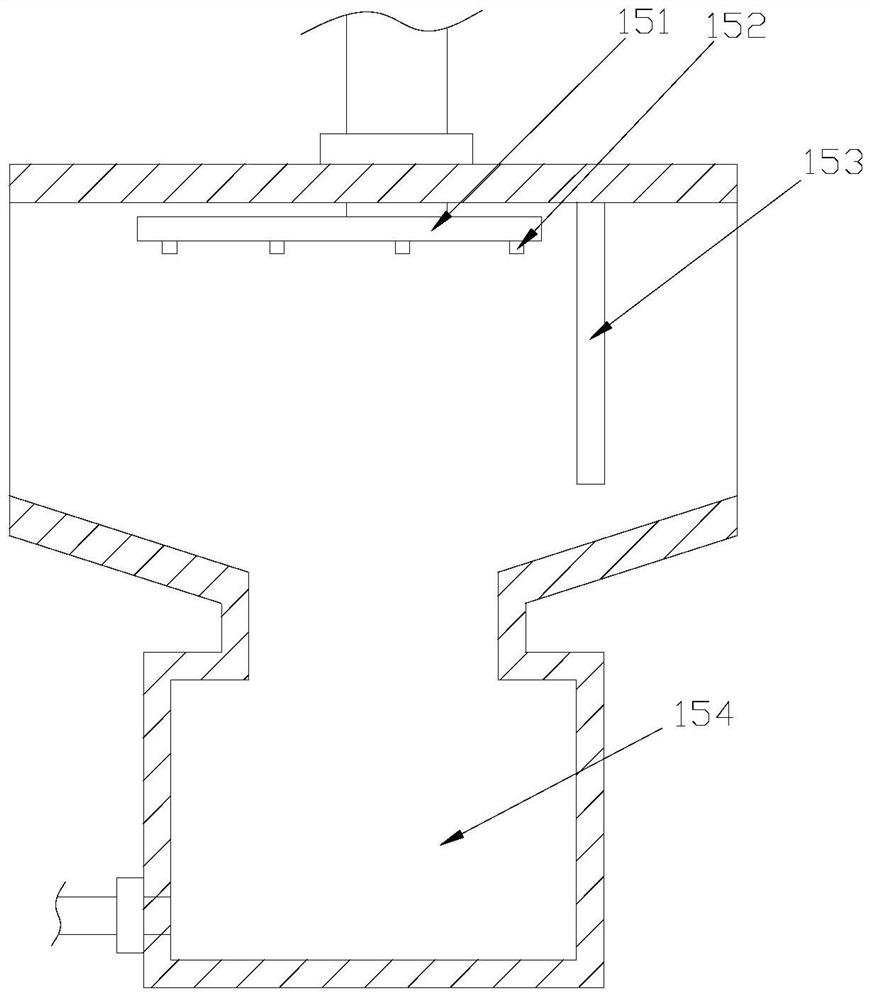

[0024] Example 1: Please refer to Figure 1-Figure 4 The specific embodiment of the present invention is as follows: its structure includes a main body 1, a control panel 2, an air inlet 3, and an air outlet 4, the upper front end of the main body 1 is provided with a control panel 2, and the air inlet 3 is arranged on the side The air outlet 4 is located directly below the control panel 2. The main body 1 includes a heating wire 11, an oxidant storage tank 12, a ventilation pipe 13, a water tank 14, and a vent 15. The heating wire 11 is installed on the main body 1. In the middle of the bottom, the oxidant storage tank 12 is arranged on the top of the heating wire 11, the ventilation pipe 13 is nested on the upper end of the oxidant storage tank 12, and two water tanks 14 are provided, and the water tanks 14 are respectively arranged on the main body 1, the vent 15 is located at the side end of the vent pipe 13, the vent 15 is provided with two, and the vent 15 is respectivel...

Embodiment 2

[0028] Example 2: Please refer to Figure 5-Figure 7 The specific embodiment of the present invention is as follows: the baffle a3 includes a support block a31, a dust shield a32, and a first spring a33, the inner side of the support block a31 is engaged with a dust shield a32, and the first spring a33 is installed In the support block a31, the first spring a33 is movably matched with the dust shield a32, which is beneficial for the first spring a33 to support the dust shield a32 to shield the through hole a2 from dust.

[0029] The dust shield a32 is composed of a first plate body b1, a sliding groove b2, a second spring b3, a second plate body b4, a third spring b5, and a clamping rod b6, and a sliding groove is provided on the inside of the first plate body b1 b2, the second spring b3 is installed inside the sliding groove b2, the second plate b4 is arranged at the side end of the first plate b1, and the bottom of the side end of the second plate b4 is connected with the th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com