Preparation method of mass type formaldehyde sensor based on functionalized SBA-15

A technology of SBA-15 and formaldehyde sensor, which is applied in the field of preparation of quartz crystal microbalance formaldehyde sensor, can solve the problems of unsatisfactory low concentration detection and pollution, and achieve the effect of easy integration, good repeatability and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

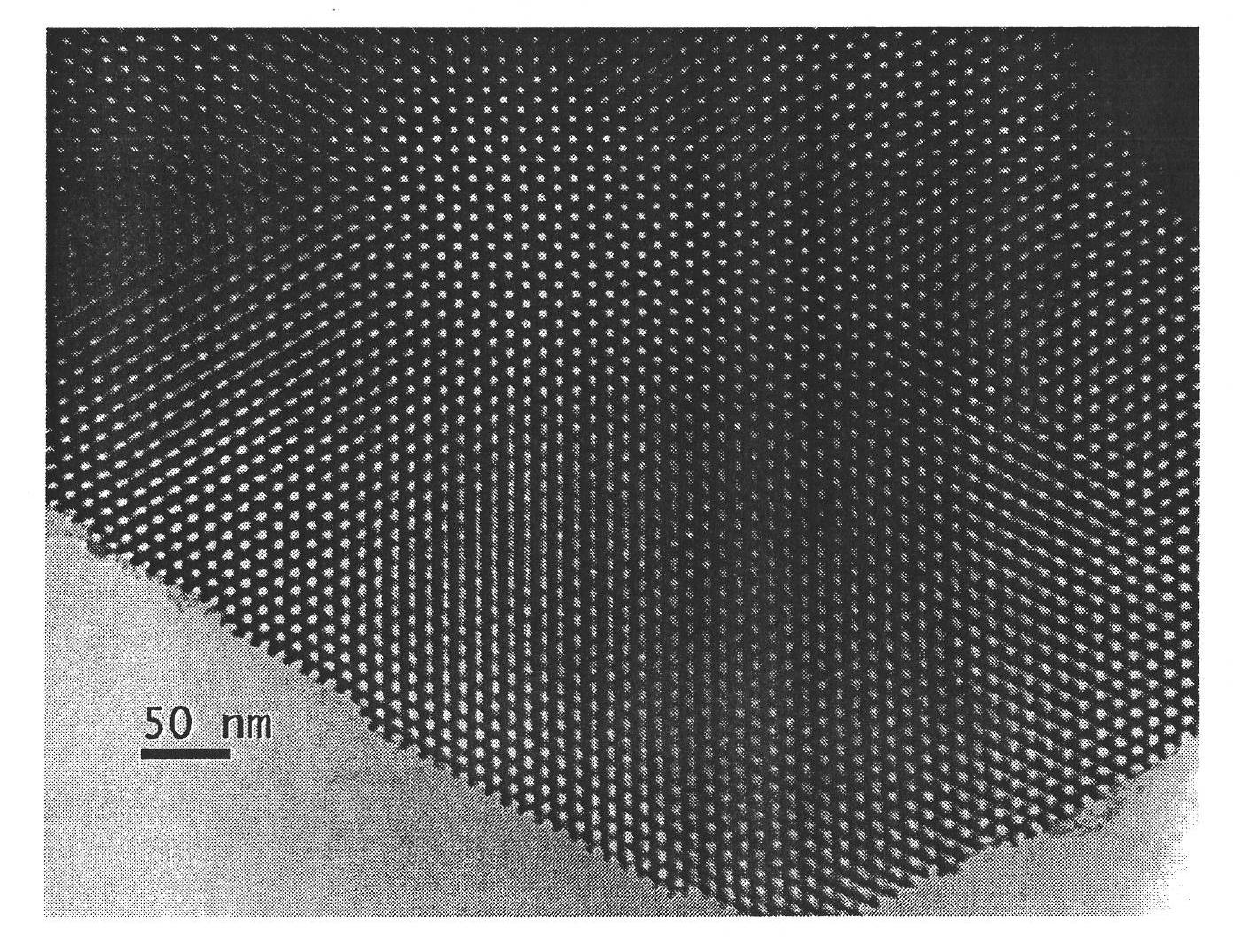

[0022] The preparation method of the amine-based functionalized mesoporous material SBA-15 quartz crystal microbalance formaldehyde sensor (QCM), the process and steps are as follows:

[0023] (1) Preparation method of amino-functionalized SBA-15: Weigh 0.3g of ordered mesoporous material SBA-15 and calcinate and activate it at 80℃ for 3h, and then add 2.2mL of silylation reagent β-carboxyethyltrimethoxy Silane was added to 4 mL of toluene solvent, mixed thoroughly, stirred at a constant speed under reflux for 20 hours, and then repeatedly washed with toluene organic solvent, filtered and dried, and the product obtained was cooled to room temperature to obtain the amino-functionalized SBA- 15.

[0024] The obtained amine functionalized SBA-15 was ultrasonically dispersed in ethanol for 30 minutes to obtain a coating solution; it was uniformly coated on the sensor electrode of a quartz crystal microbalance (QCM), and dried at 80-120°C for 3 hours. Finally, a formaldehyde sensor is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com