Cold volatilization type formaldehyde removal device and working principle thereof

A volatile and formaldehyde-based technology, which is applied in gas treatment, transportation and packaging, and dispersed particle filtration, etc. It can solve the problems of dependence and the effect of removing aldehydes to be discussed, and achieve no consumable loss, low mold opening cost, and better results. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

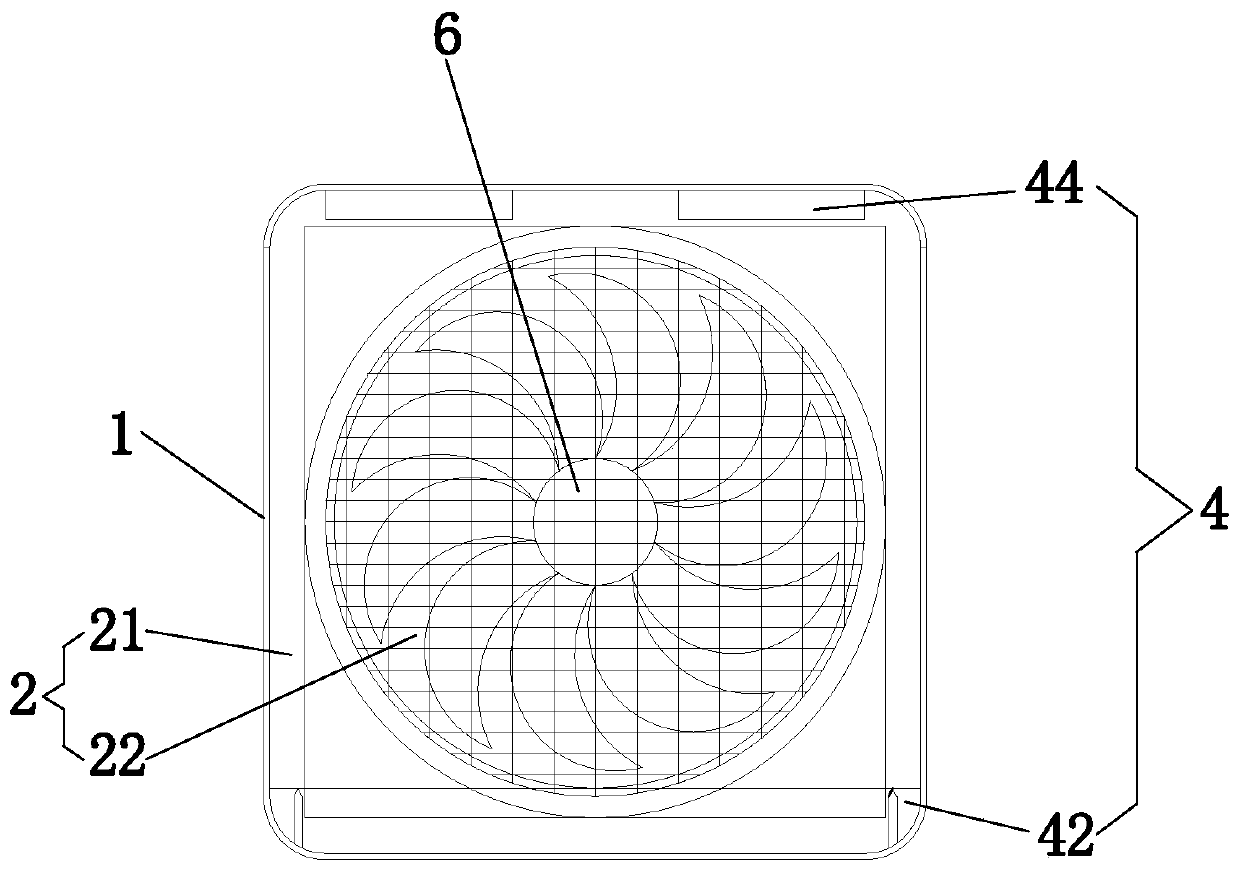

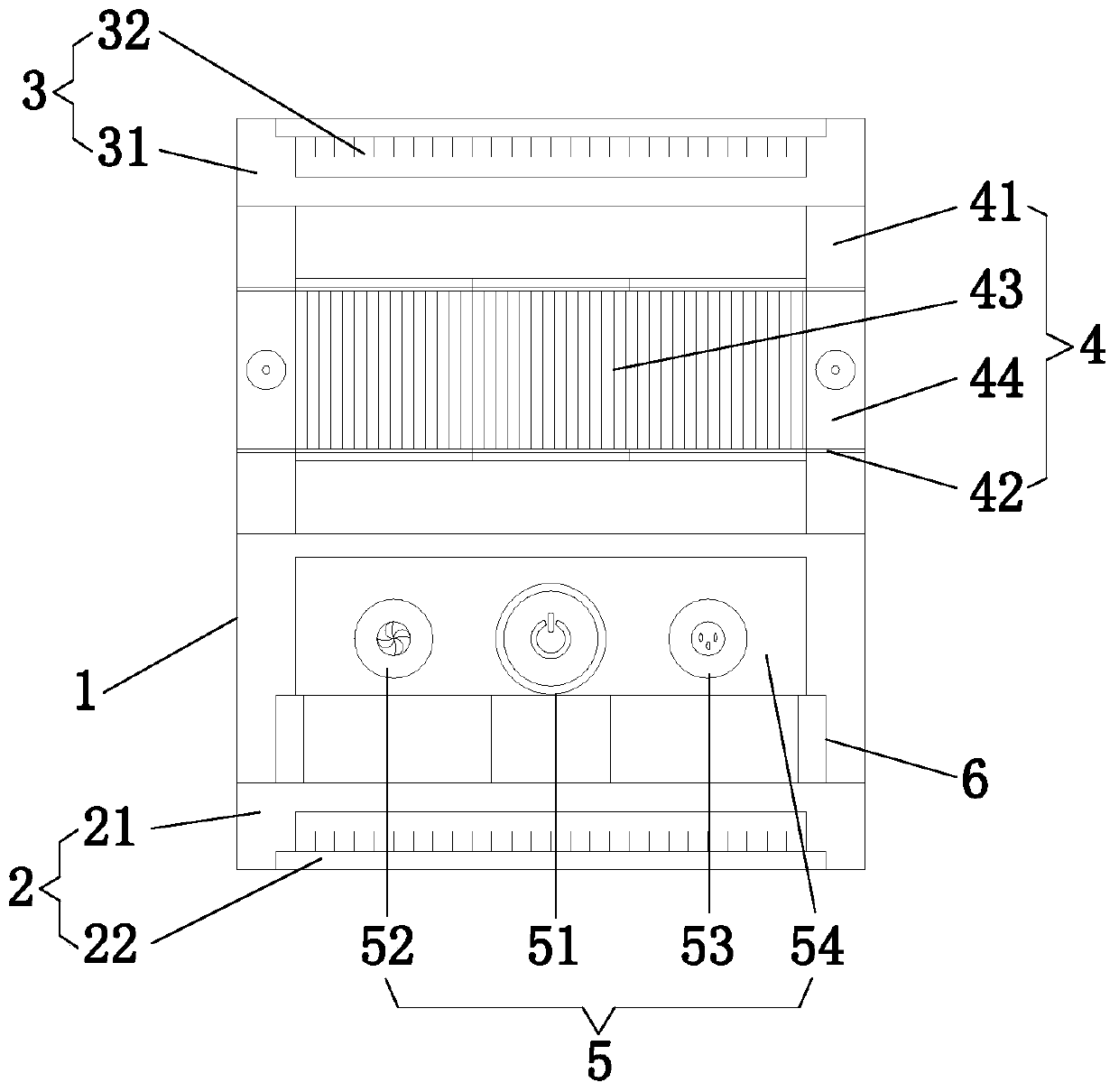

[0046] The specific operation is as follows:

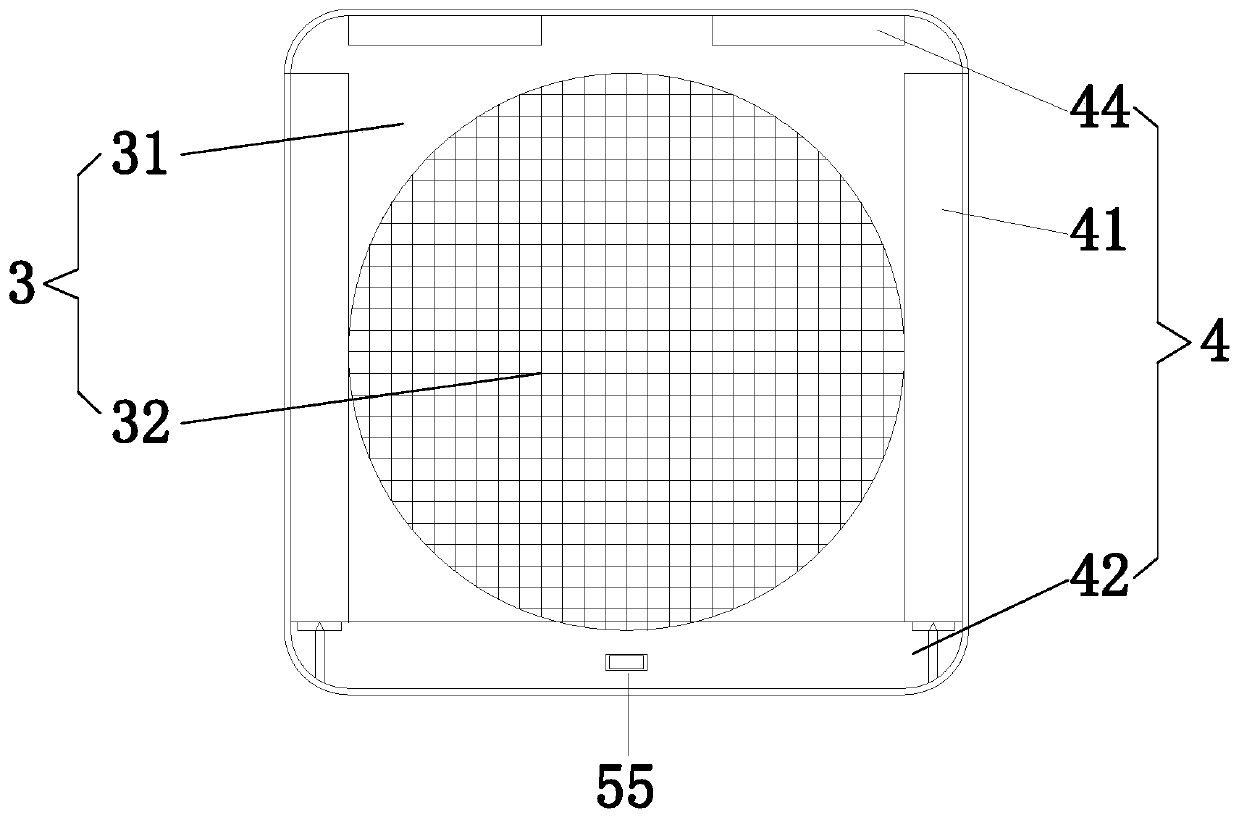

[0047] 1) Remove the cover plate 44 from the equipment, take out the water tanks 41 on both sides, add 100 mL of formaldehyde-removing active liquid (compound amino acid active liquid, aqueous solution, solid content 9%) to the left water tank, and add 100 mL of purified water to the right;

[0048] 2) Insert the water tank 41 into both sides of the equipment, that is, place it on both ends of the water storage tank;

[0049] 3) Place the wet curtain 43 vertically on the water storage tank, cover the cover plate 44, and wait for 10 minutes to get wet;

[0050] 4) Insert the power cord into the power socket, and place the device in a formaldehyde concentration of 1.012mg / m 3 3m 3 In the environmental chamber, connect the power cord to the power supply, click the power button to turn on the power (the power symbol on the power button is lit at this time), and click the air volume adjustment button to adjust the air volume to the m...

Embodiment 2

[0054] The specific operation is as follows:

[0055] 1) Remove the cover plate 44 from the equipment, take out the water tanks 41 on both sides, pour out the liquid in the two water tanks, and add 100 mL of formaldehyde-removing active liquid (compound amino acid active liquid, aqueous solution, solid content 6%) to both water tanks;

[0056] 2) Remove the remaining liquid in the water storage tank 42, and insert the water tank 41 containing the active liquid into both sides of the equipment, that is, place it on both ends of the water storage tank;

[0057] 3) Take an unused wet curtain 43 and place it vertically on the water storage tank 42, cover it with a cover plate 44, and wait for 10 minutes to get wet;

[0058] 4) Insert the power cord into the power socket, and place the device in a formaldehyde concentration of 1.124mg / m 3 3m 3 In the environmental chamber, connect the power cord to the power supply, click the power button to turn on the power (the power symbol on...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Horizontal spacing | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com