Preparation method and application of nanoscale Co3O4 (at) Pt

A nano-scale, nano-particle technology, which is applied in the preparation of carboxylate, chemical instruments and methods, and the preparation of organic compounds, etc., can solve the problem of affecting the catalytic activity and cycle stability of catalysts, different sizes, weak interaction, etc. problem, to achieve good flexibility and adaptability, low cost and short time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

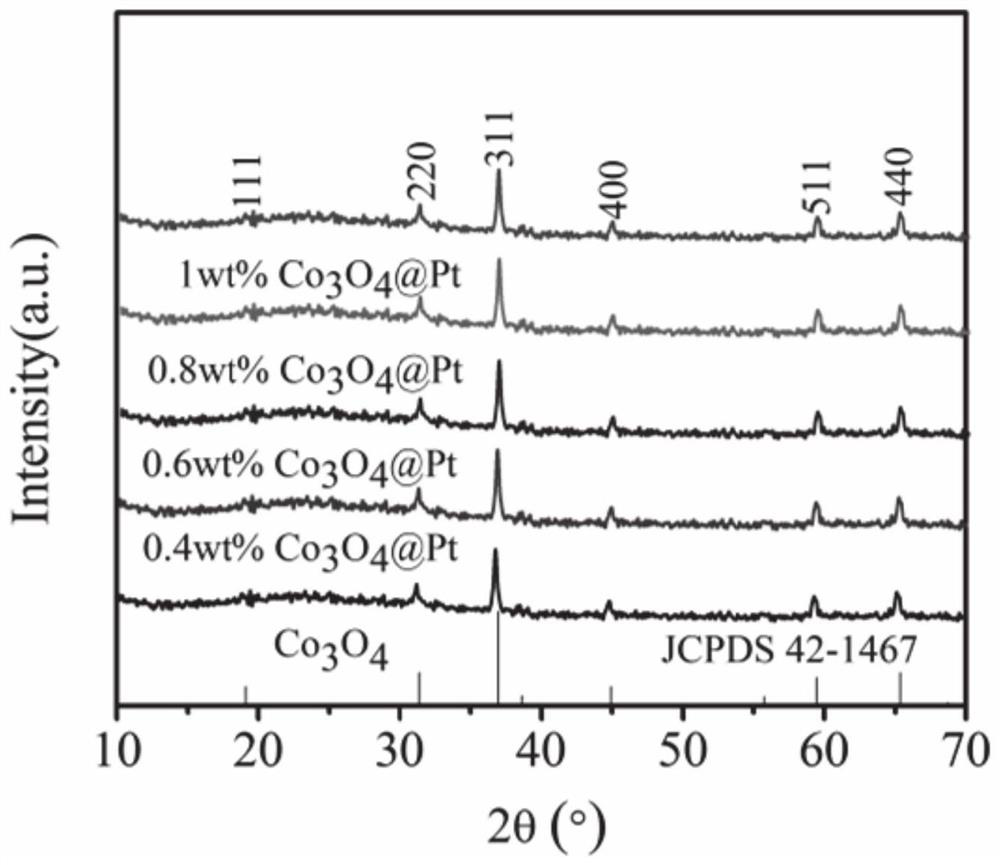

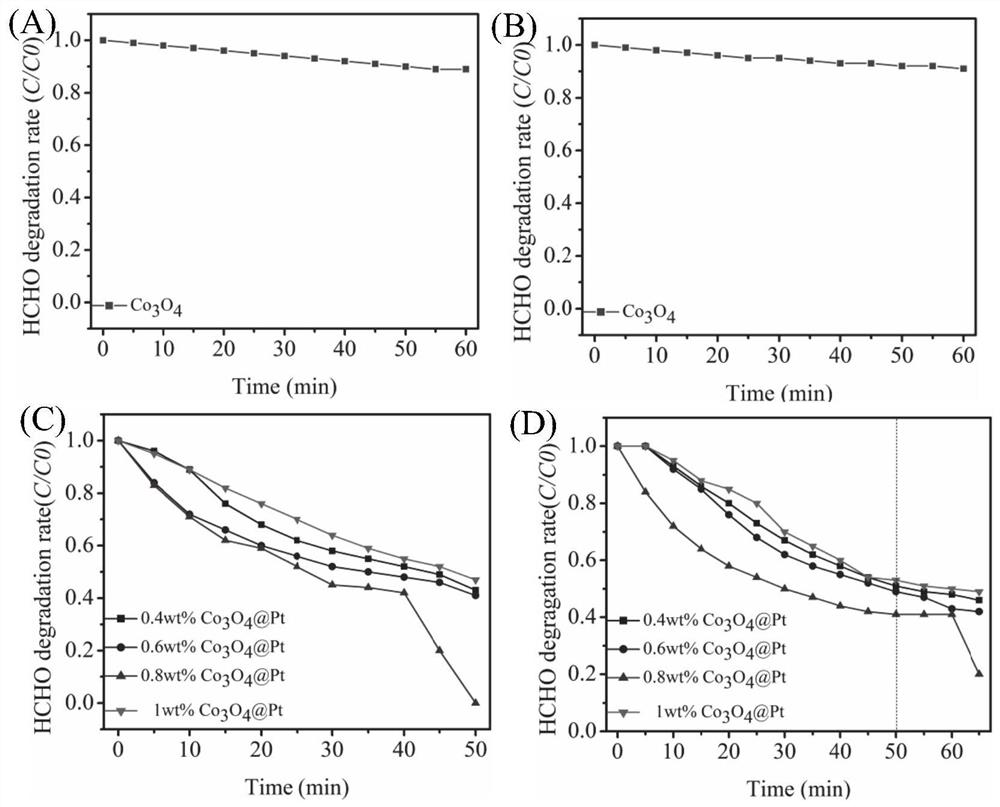

[0023] In the first aspect of the present disclosure, there is provided a nanoscale Co 3 o 4 @Pt redox preparation method, including: to nano-scale Co 3 o 4 Adding a solution containing Pt in a non-zero oxidation state, a redox reaction occurs between Co(II) and Pt in a high oxidation state, so that the reduction product Pt nanoparticles are loaded on the nanoscale Co 3 o 4 s surface.

[0024] In a typical embodiment, the solution containing Pt in a non-zero oxidation state is a chloroplatinic acid solution, and its solution concentration is 0.5-2 mg / L; further, chloroplatinic acid and nano-scale Co 3 o 4 The mass ratio is 1:30~100.

[0025] In a typical implementation, the preparation method is specifically: to the prepared Co 3 o 4 Add H to the suspension 2 PtCl 6 ·6H 2 After the O solution was mixed evenly, the Co was obtained after separation, washing and drying. 3 o 4 @Pt heterojunction nanomaterials.

[0026] Further, the loading amount of Pt is 0.4wt%-1wt%...

Embodiment 1

[0056] (1) 0.05g cobalt nitrate hexahydrate (Co(NO 3 ) 2 ·6H 2 O) and 0.02g of urea were dissolved in 3.5mL of ethylene glycol and 13.5mL of distilled water mixed in a homogeneous solution, vigorously stirred for 2 hours;

[0057] (2) Put it into a 30mL polytetrafluoroethylene autoclave. Then put the polytetrafluoroethylene reaction kettle in a digital display blast drying oven at 180°C, and conduct a hydrothermal reaction for 40 minutes;

[0058] (3) Naturally cool to room temperature, wash with deionized water and ethanol three times respectively, and finally put the washed product into an oven at 80° C. to dry overnight;

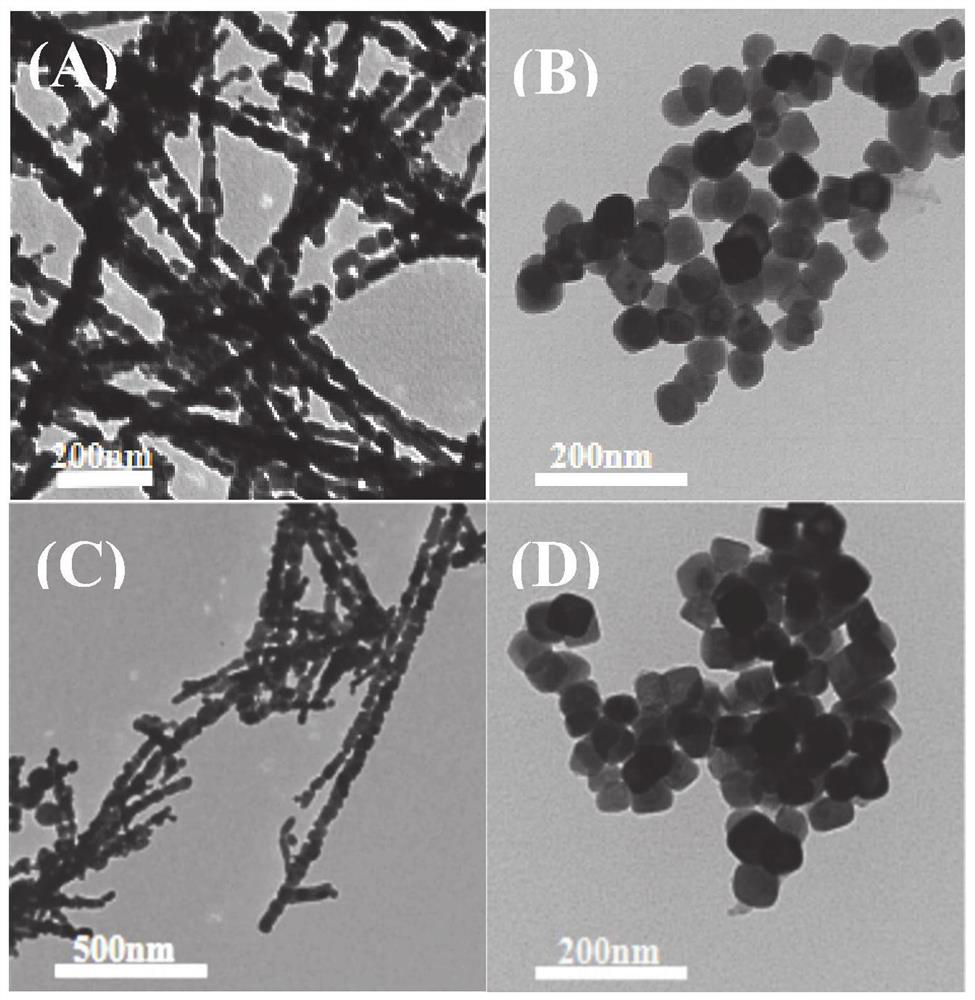

[0059] (4) The precursors prepared above were calcined and placed in air at 400 °C at a heating rate of 2 °C / min for 2 hours to obtain rod-shaped Co 3 o 4 .

Embodiment 2

[0061] (1) 0.0728g cobalt nitrate hexahydrate (Co(NO 3 ) 2 ·6H 2 O) Dissolve in 10 mL of deionized water, then slowly add 10 mL of 0.1M NH 3 ·H 2 O, the color changed from pink to blue, stirred on a magnetic stirrer for 15min and mixed evenly, then turned dark green, then washed the precipitate with deionized water and centrifuged for 6 times, then added 20mL (V 甲醇 :V 水 =1:1) methanol aqueous solution, finally add 0.3g NaNO 3 Mix evenly and transfer to polytetrafluoroethylene reactor;

[0062] (2) Put the polytetrafluoroethylene reaction kettle in a 220°C digital display blast drying oven, and perform a hydrothermal reaction for 27 hours;

[0063] (3) After naturally cooling to room temperature, pour out the supernatant in the reaction kettle to obtain a black precipitate; respectively wash and centrifuge 3 times with deionized water and ethanol ultrasonically;

[0064] (4) Finally, put the washed product in an oven at 60°C and dry it overnight to obtain spherical Co 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Quality | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com