Piezoelectric catalytic film used in air purifier and preparation method thereof

An air purifier and catalytic membrane technology, applied in chemical instruments and methods, catalyst activation/preparation, physical/chemical process catalysts, etc., can solve problems such as complex implementation conditions, and achieve the effect of good piezoelectric catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Example 1 Preparation and Power Generation Performance of Piezoelectric Catalytic Film

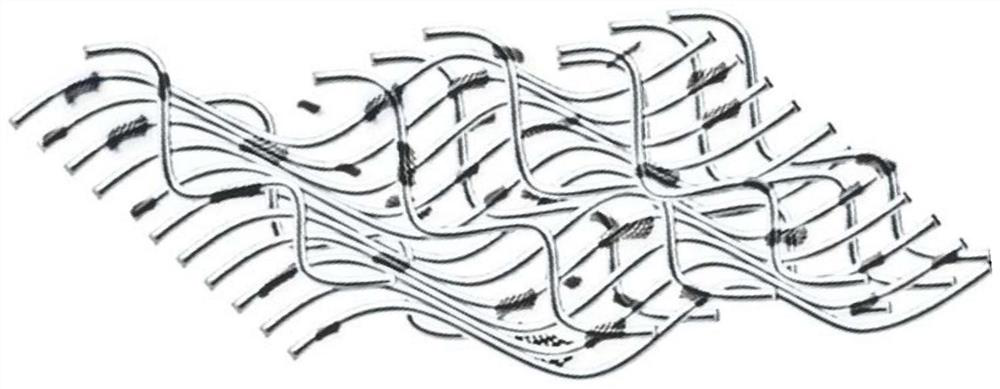

[0028] Attached below figure 1 Embodiments of the present invention are further described:

[0029] First prepare the precursor mixed solution: weigh 0.0204~0.1111g of carbon black (or graphene or carbon nanotubes) and 1g of polyvinylidene fluoride-hexafluoropropylene particles into 5-10ml of acetone, dissolve and disperse at room temperature for 6 hours, to obtain the spinning solution; weigh 0.0204~0.1111g carbon black (or graphene or carbon nanotubes) and 1g polyvinylidene fluoride-hexafluoropropylene particles into 10-20ml acetone, dissolve at room temperature, add 1 -3ml of water to obtain a phase-separated spray solution.

[0030] Porous membrane preparation on fabrics by electrospinning or phase-separation spray coating.

[0031] Then stand at room temperature for 24 hours to obtain a porous polyvinylidene fluoride-hexafluoropropylene composite membrane;

[0032] The comp...

Embodiment 2

[0033] Embodiment 2 Piezoelectric catalytic membrane catalytic performance

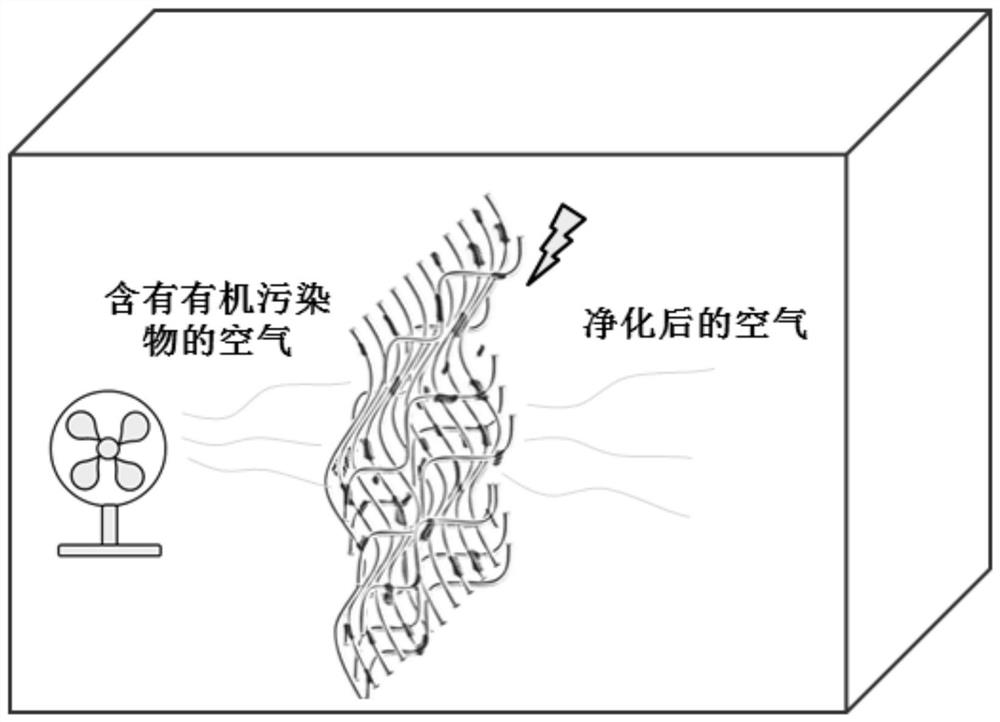

[0034] Attached below figure 2 Embodiments of the present invention are further described:

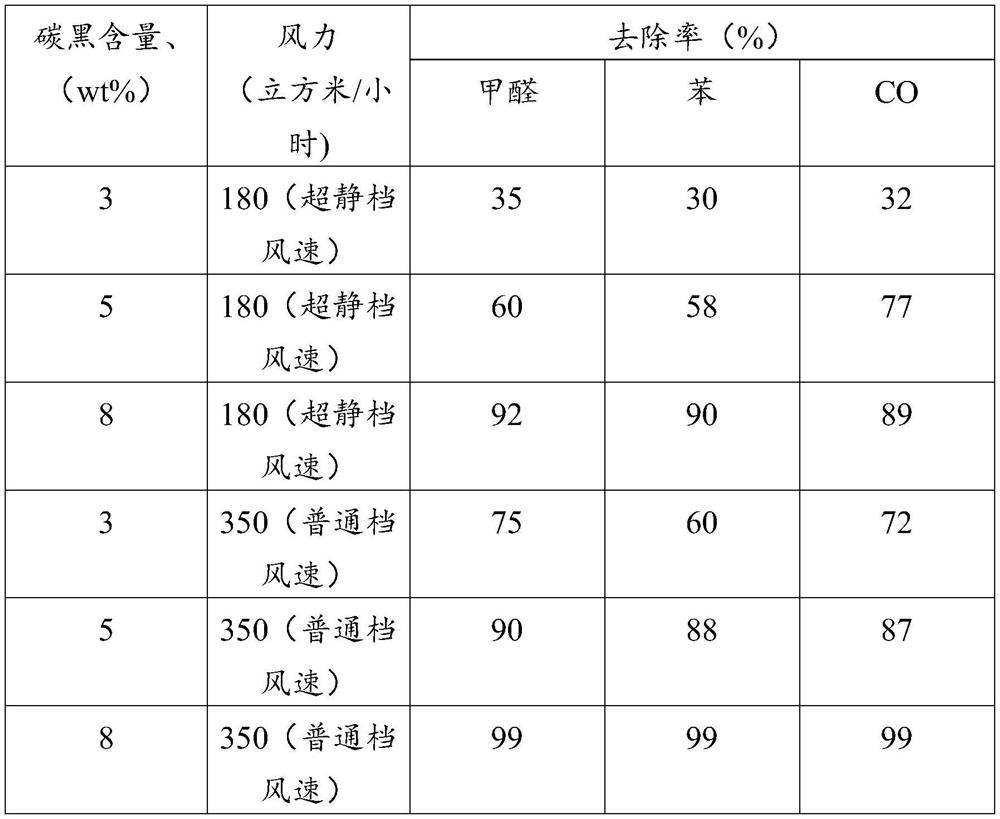

[0035] Prepare porous polyvinylidene fluoride-hexafluoropropylene composite films (3, 5, 8wt%) with different carbon black contents on commercial filter screens of the same area. The commercial filter screen has only filtering function and no catalytic function. After the ethylene-hexafluoropropylene composite porous piezoelectric catalytic membrane, the effects of carbon black content and wind force on the removal rate of indoor organic pollutants were tested. Table 1 shows the removal effects of different carbon black contents and wind power on formaldehyde, benzene, and CO. The test conditions were 30 flat indoor environments, and the purification was performed for 1 hour.

[0036] Table 1 The removal effect of different carbon black contents and wind power on formaldehyde, benzene and CO

[0037]

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com